Oxidation ditch system with synergistic interaction of spiral-flow aeration and plug flow nozzles

A technology of synergistic efficiency and oxidation ditch, applied in the field of oxidation ditch system, can solve the problems of inability to directly measure the oxygen mass transfer efficiency of aerators, difficult working conditions of impellers, and heavy maintenance workload, so as to improve the effect of oxygen supply. , The effect of preventing activated sludge precipitation and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

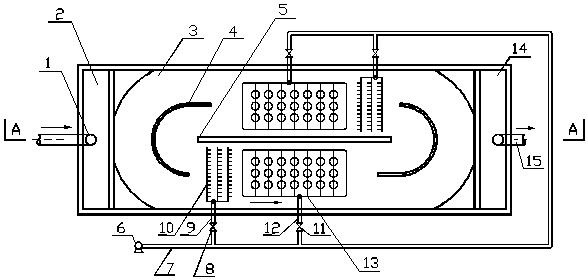

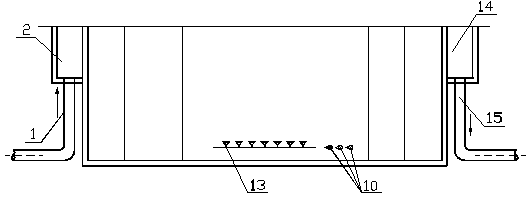

[0012] Such as figure 1 As shown, an embodiment of the present invention includes an inlet ditch 2 and an outlet ditch 14 arranged at both ends of the oxidation ditch 3 and communicated with the oxidation ditch 3; the bottom of the inlet ditch 2 and the outlet ditch 14 are respectively provided with an inlet pipe 1 and an outlet pipe 15. A partition wall 5 is arranged in the oxidation ditch 3 along the water flow direction, and an arc-shaped island 4 is arranged in the oxidation ditch at both ends of the partition wall 5; A push flow nozzle 10 and a swirl shear bubble aerator 13 are provided in sequence, and each of the push flow nozzle 10 and the swirl shear bubble aerator 13 communicates with the air supply main pipe 7 through an air supply branch pipe 9,12 , the air supply main pipe 7 communicates with the blower 6, and the air supply branch pipes 9, 12 are provided with control and regulating valves 8, 11.

[0013] The working process of the synergistic oxidation ditch sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com