Wet-method atmospheric oxidation method of cerium in rare earth hydroxides

A rare earth hydroxide and air oxidation technology, applied in the direction of improving process efficiency, can solve the problems of time-consuming, labor-intensive and large consumption, and achieve the effect of reducing water consumption and avoiding dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare a rare earth nitrate solution with a concentration of 25g / L, add NaOH to adjust the alkalinity of the mixed slurry to 0.1mol.L -1 , Add sodium fluoride according to F / TCeO=1, and pass in 1L / min of compressed air at 80℃. After 4h, the oxidation rate of Ce(III) in the solution reaches 96.13%.

Embodiment 2

[0033] Prepare a rare earth chloride solution with a concentration of 50g / L, add NaOH to adjust the alkalinity of the mixed slurry to 0.5mol.L -1 , Add ammonium fluoride according to F / TCeO=3, and pass in 4L / min of compressed air at 100℃. After 10h, the oxidation rate of Ce(III) in the solution reaches 96.90%.

Embodiment 3

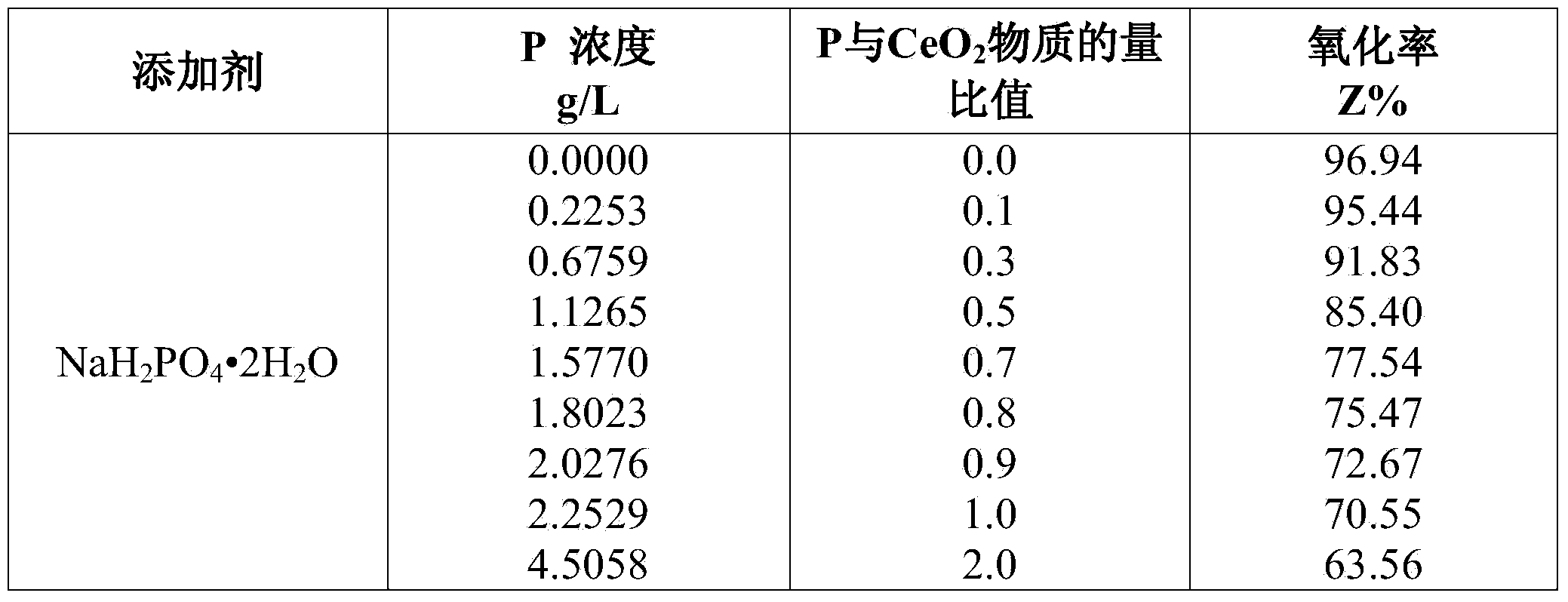

[0035] Prepare a rare earth nitrate solution with a concentration of 10g / L, and add NaOH to adjust the alkalinity of the mixed slurry to 1.0mol.L -1 , Add sodium dihydrogen phosphate according to P / TCeO=0.3, and pass in 0.5L / min of compressed air at 25℃. After 0.5h, the oxidation rate of Ce(III) in the solution reaches 89.58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com