Combination type sealing gasket

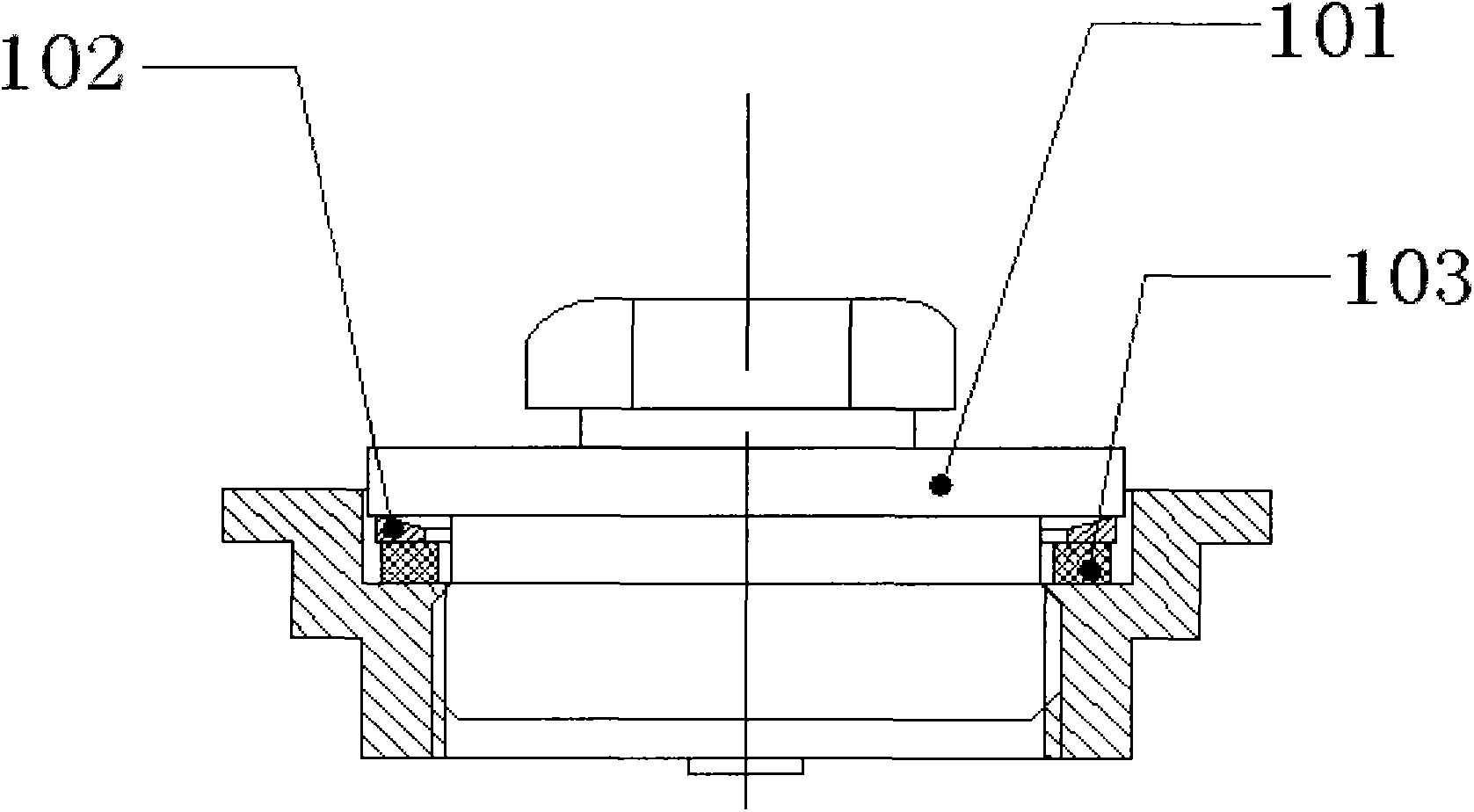

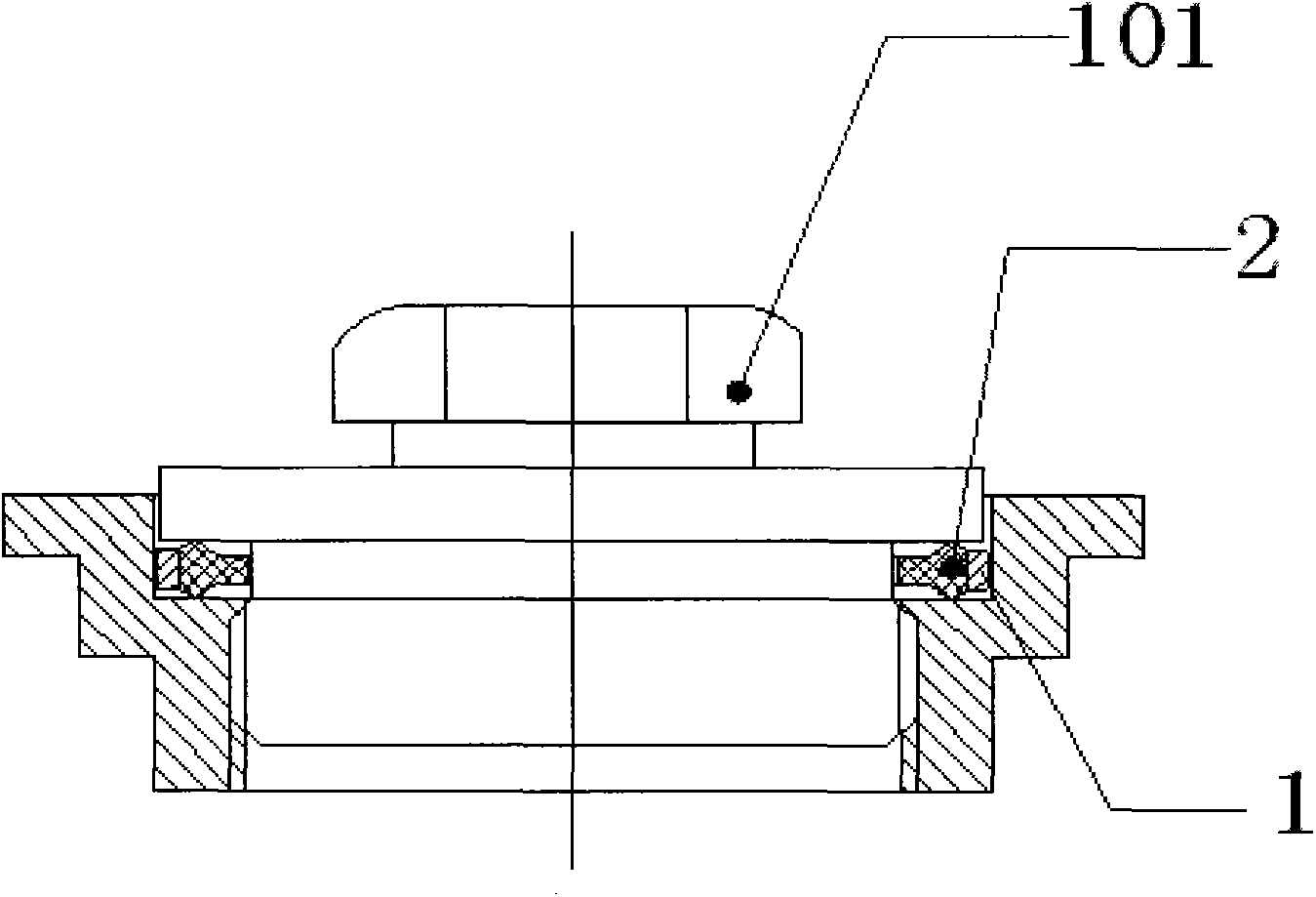

A kind of sealing gasket and combined technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of excessive compression, easy loss of the sealing gasket of the expansion water tank, etc., to achieve good sealing, good heat dissipation effect, and improve work reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] In this embodiment, the material selection and setting details of the combined sealing gasket are described in detail in combination with the requirements of specific working conditions.

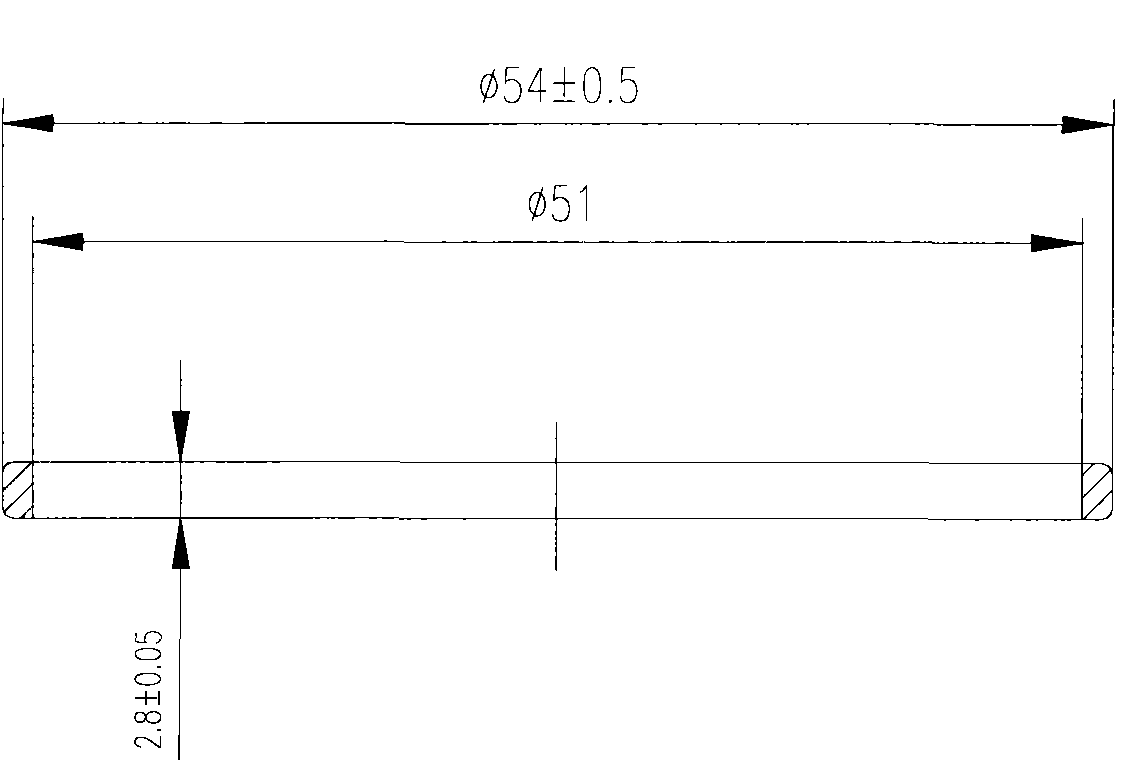

[0027] First of all, according to the characteristics of the selected rubber material, the calculation of the size chain of the water inlet cover and the water inlet seat, the optimal thickness of the rubber ring is 1.1mm, and the thickness of the steel ring is 2.8mm, such as image 3 shown.

[0028] Secondly, 8 internal teeth are designed on the inner side of the apron, and the diameter of the internal teeth is calculated to be ¢42 according to the size of the relief groove of the water inlet cover, which prevents it from falling off from the water inlet cover and facilitates maintenance and replacement, such as Figure 4 shown.

[0029] Finally, sand blast the inner surface of the steel ring, and vulcanize the rubber and the inside of the steel ring together in the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com