Metal self-lubrication piston ring

A self-lubricating and ring-expanding technology, applied in the field of ring-expanding and metal self-lubricating ring-expanding, can solve the problems of easy deformation, leakage of impurity particles, insufficient circulation of liquid in the trough, etc., and achieves improved elasticity, good heat dissipation, and improved sealing performance. and the effect of sealing surface lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

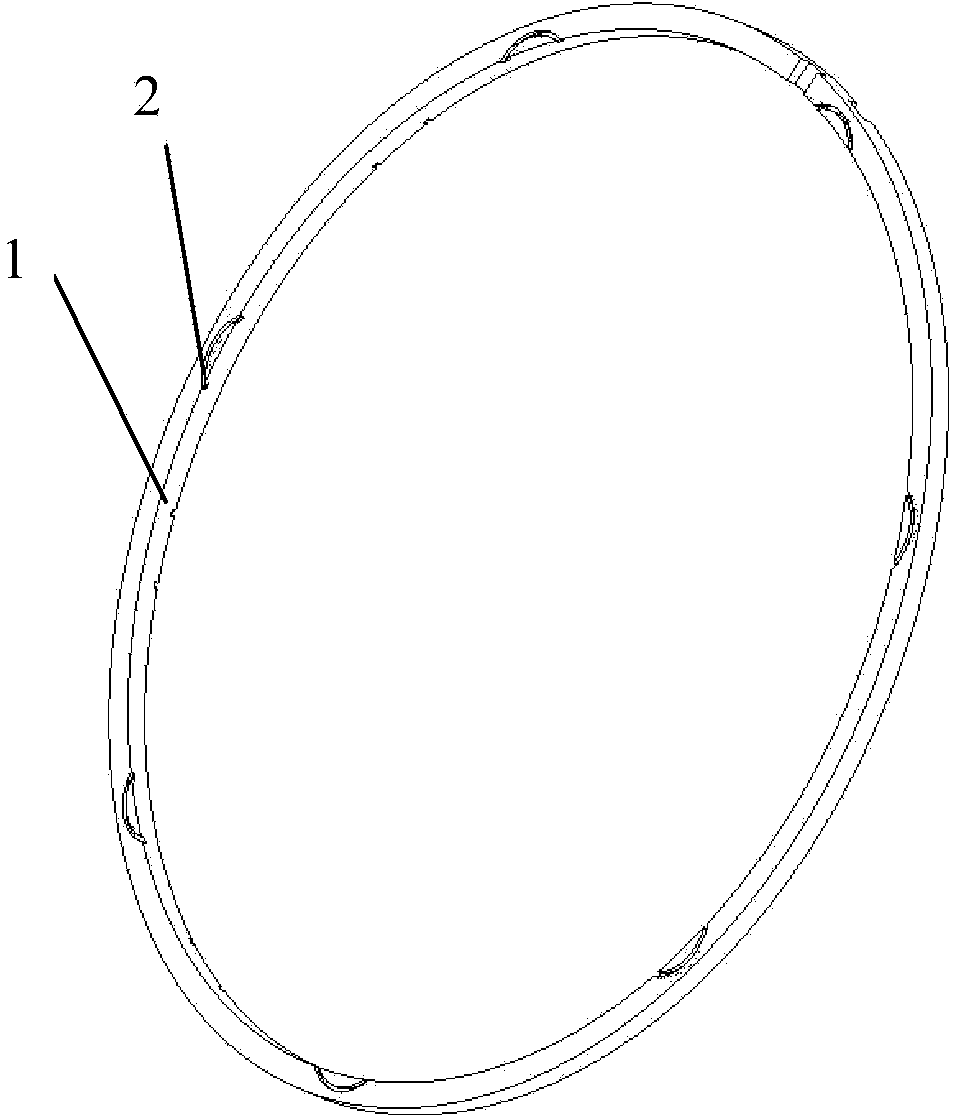

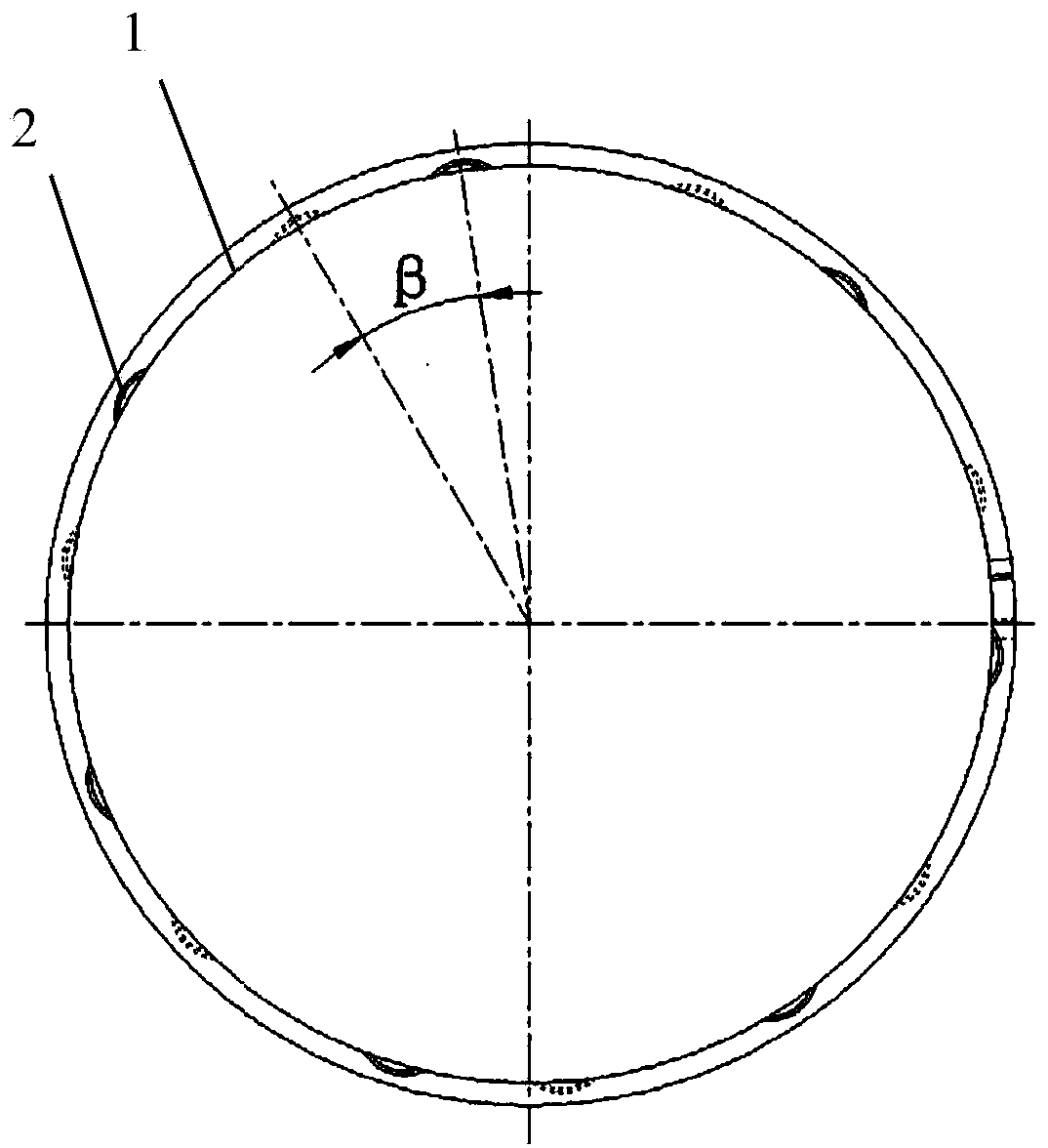

[0019] to combine figure 1 , figure 2 , the metal self-lubricating expansion ring proposed by the present invention is described in detail.

[0020] The present invention proposes a metal self-lubricating expansion ring, which includes an expansion ring body 1, and the expansion ring body 1 includes a positive sealing surface and a reverse sealing surface, wherein the positive sealing surface is provided with an arc groove 2, when the fluid passes through the arc groove 2. Generate thermohydrodynamic wedge effect, improve the sealing performance of the expansion ring and the lubrication of the sealing surface.

[0021] Preferably, in the case that the expansion ring needs to be sealed on both sides, the anti-sealing surface of the expansion ring is also provided with an arc groove 2 .

[0022] In order to improve fluidity and heat dissipation when using the expander ring, a plurality of circular arc grooves 2 are respectively arranged on the positive sealing surface and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com