Microbubble-generating device, microbubble-generating method, and gas-liquid reaction method using same

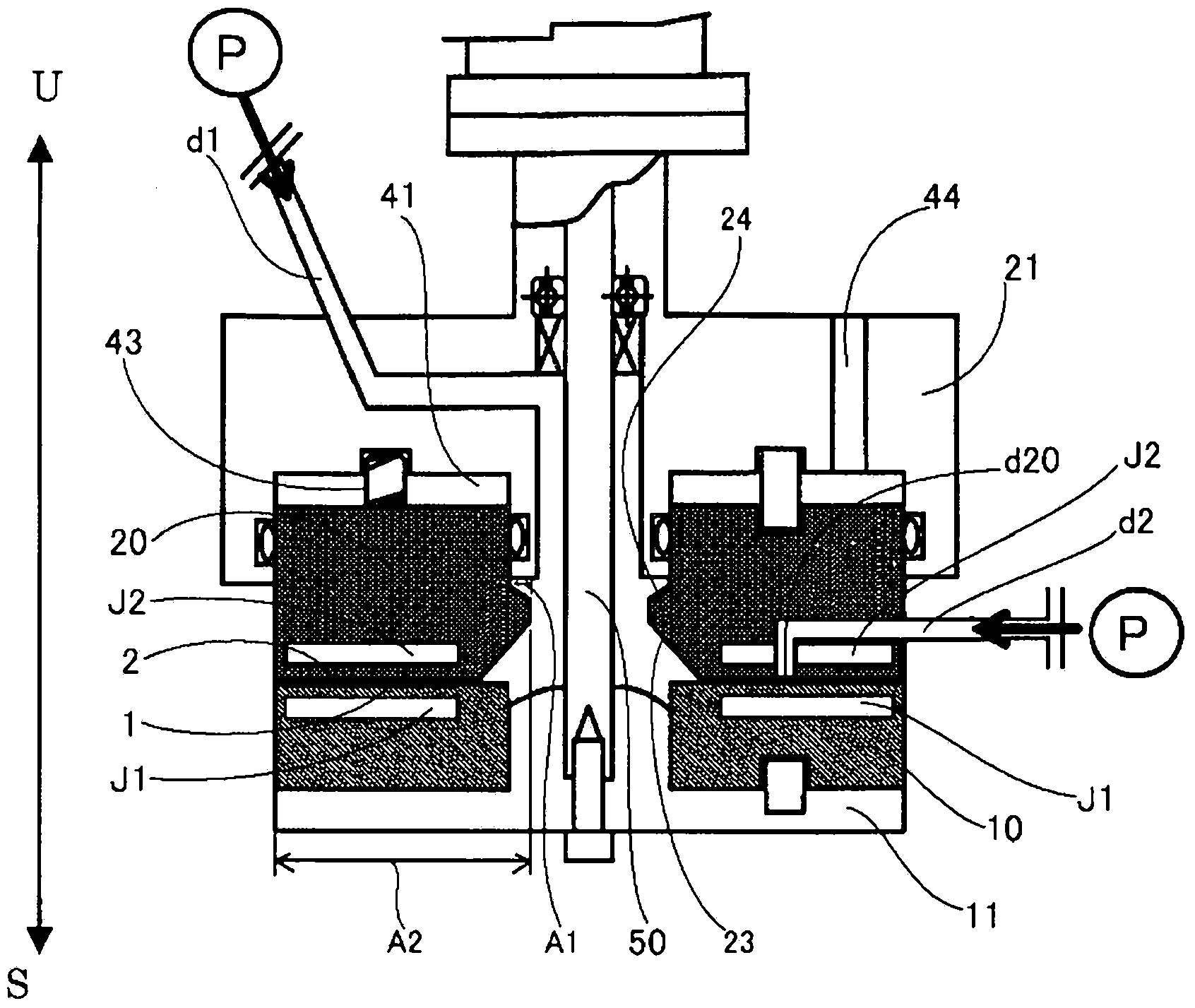

A bubble generating device and technology for generating bubbles, which are applied in the direction of film-type liquid-gas reaction, gas/vapor and liquid mixing, mixers with rotary stirring device, etc. Efficiency effect of gas-liquid reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

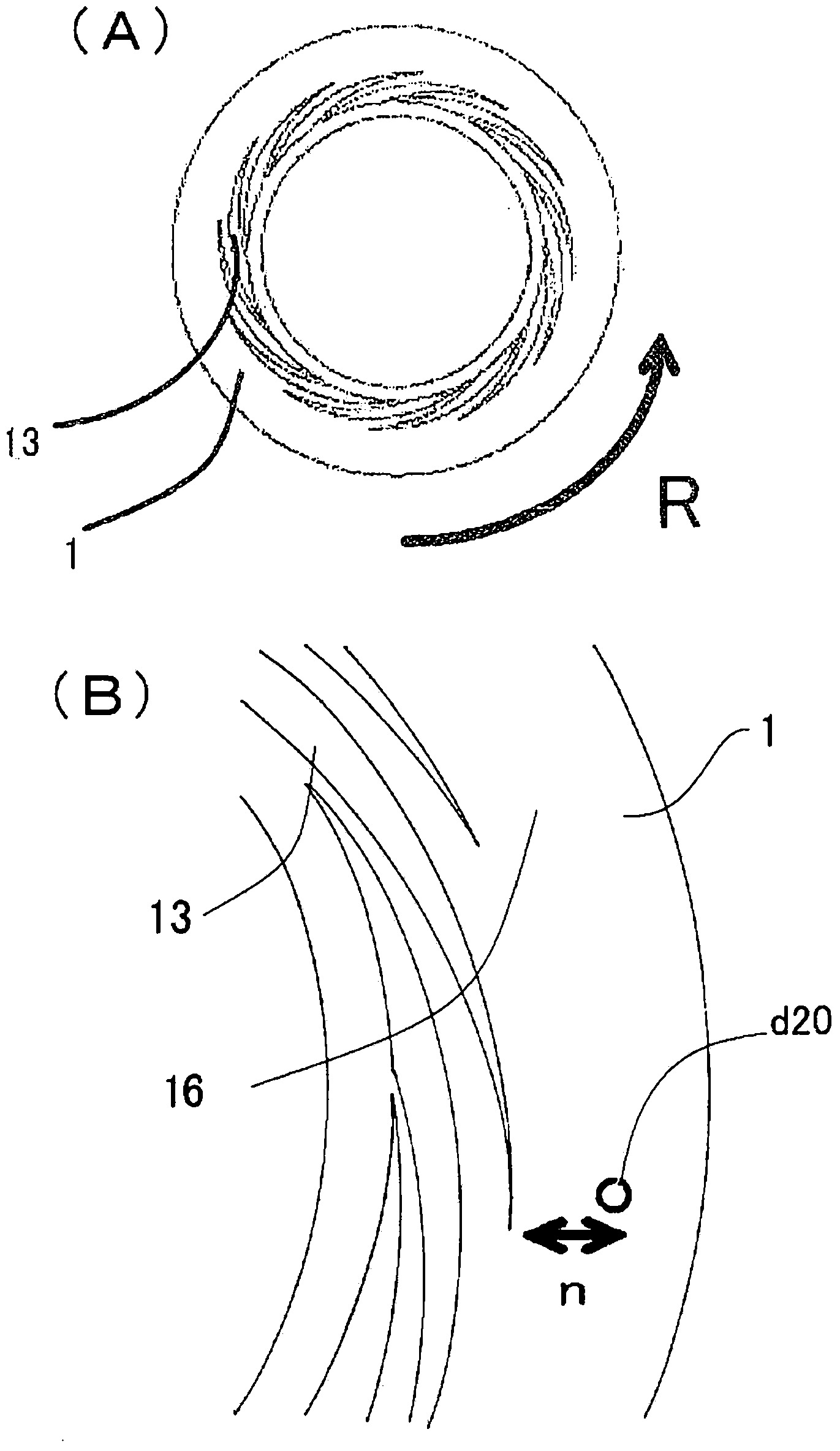

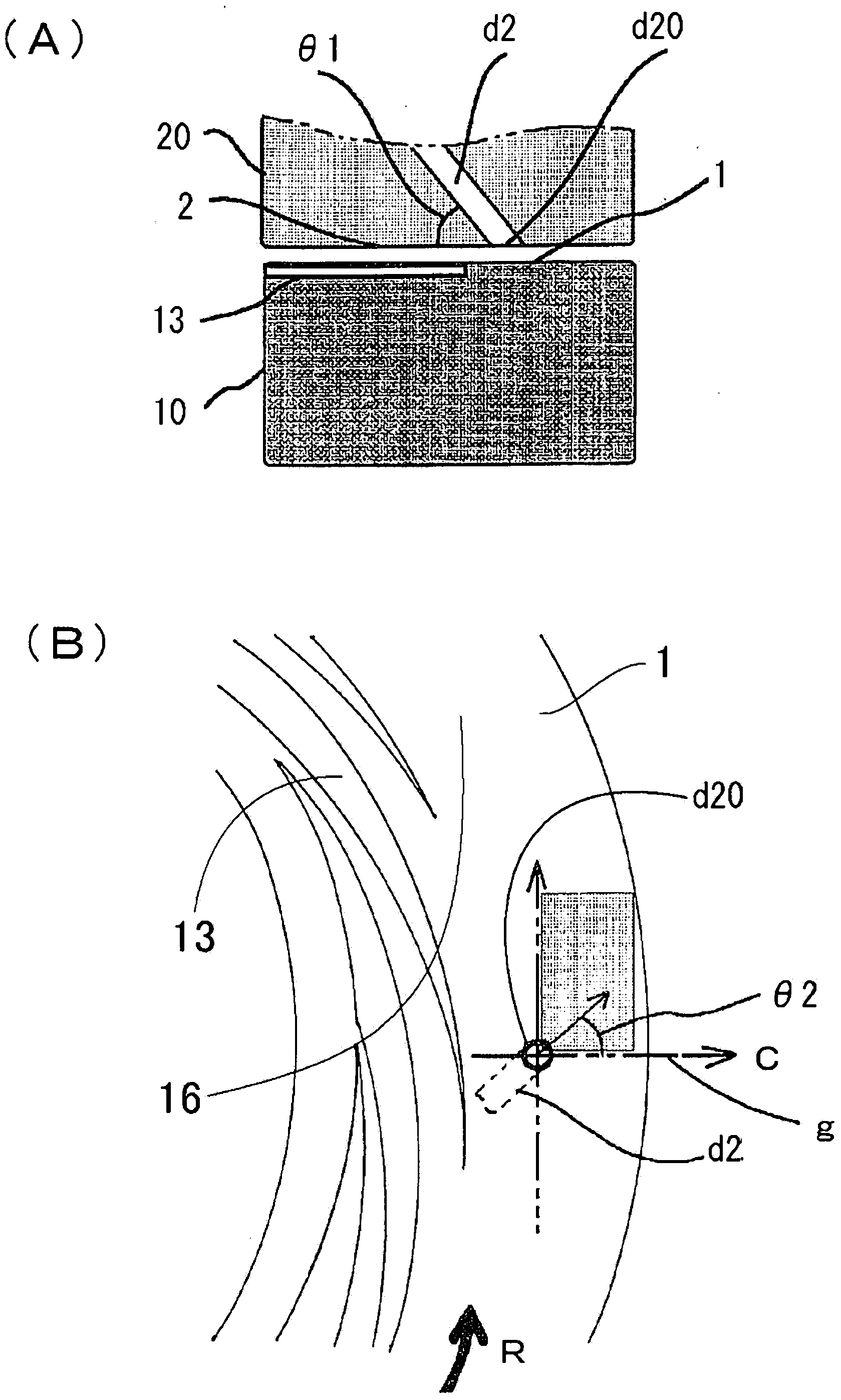

[0087] The liquid sodium hydroxide solution as the first fluid is fed from the center at the supply pressure = 0.30 MPaG and the rotation speed in Table 1, and at the same time, carbon dioxide gas (carbon dioxide gas) as the second fluid gas is introduced at 25°C. Between surfaces 1 and 2, the first fluid and the second fluid are mixed in the film fluid. The feeding temperatures of the first fluid and the second fluid were measured by measuring the respective temperatures of the first fluid and the second fluid immediately before being introduced into the processing apparatus (more specifically, immediately before being introduced between the processing surfaces 1 and 2). The liquid containing sodium bicarbonate is discharged from the treatment surfaces 1, 2. The liquid containing the discharged sodium bicarbonate was dried and solidified in an evaporator, and thermally decomposed to change the sodium bicarbonate into sodium carbonate. Thereafter, the amount of sodium carbona...

Embodiment 5~8

[0094] From the center, the SDS aqueous solution as the liquid of the first fluid is fed at the supply pressure = 0.30 MPaG and the rotation speed of Table 2, and at the same time, nitrogen gas as the gas of the second fluid is introduced at 25°C between the processing surfaces 1 and 2. The first fluid and the second fluid are mixed in the thin film fluid. The feeding temperatures of the first fluid and the second fluid were measured by measuring the respective temperatures of the first fluid and the second fluid immediately before being introduced into the processing apparatus (more specifically, immediately before being introduced into the space between the processing surfaces 1 and 2). The liquid containing fine bubbles of nitrogen gas is discharged from the processing surfaces 1 and 2 . The liquid containing the discharged nitrogen gas was observed with an optical microscope to confirm the bubble particle size of nitrogen gas.

[0095] [Table 2]

[0096]

[0097] As c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com