Air intake structure for internal combustion engine

A technology of internal combustion engine, construction, applied in the direction of fuel air intake, internal combustion piston engine, combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

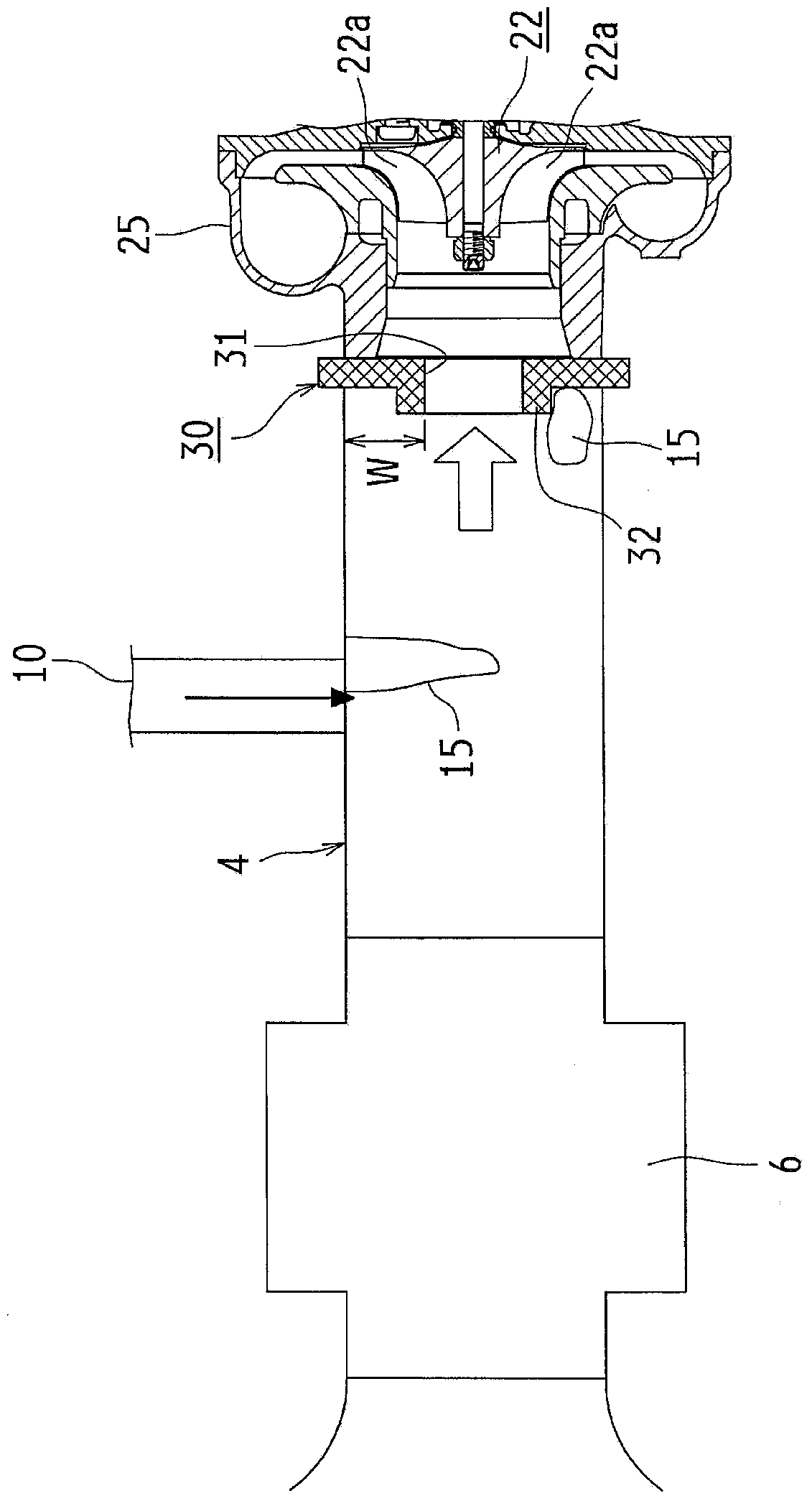

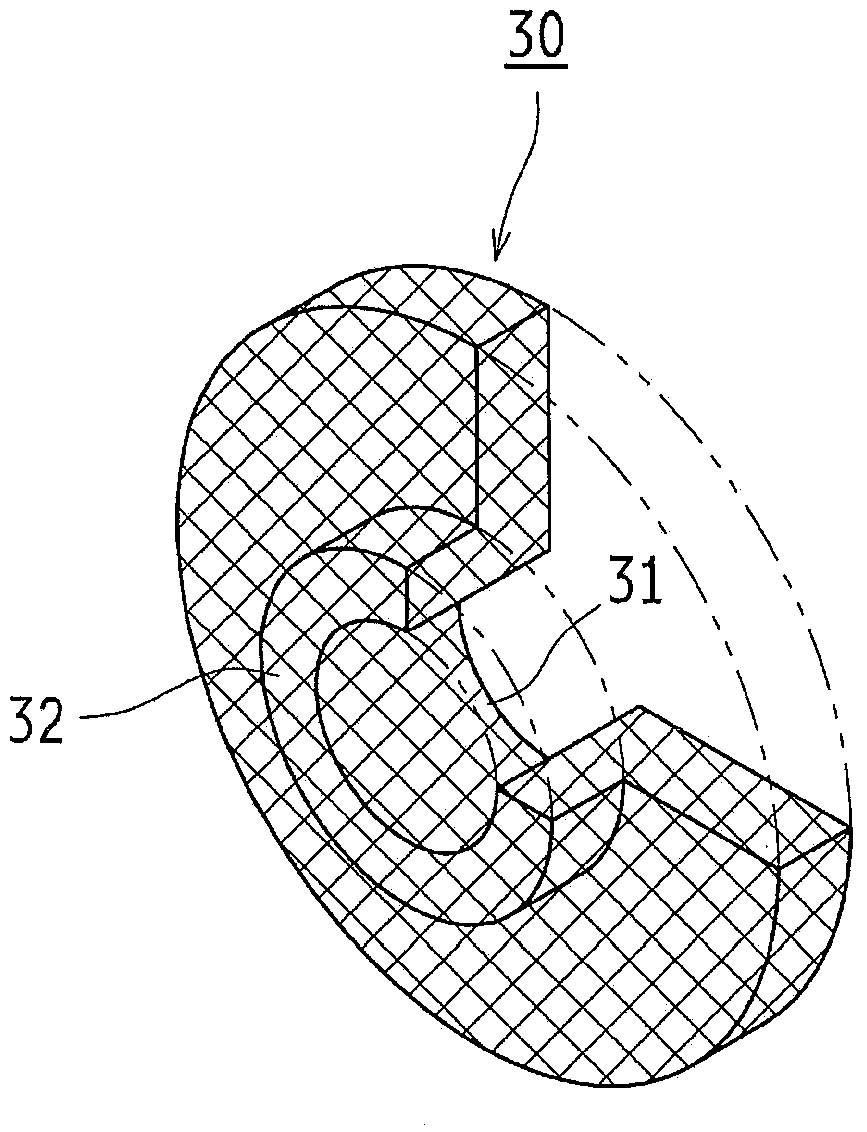

[0037] Hereinafter, preferred embodiments for carrying out the present invention will be described in detail with reference to the drawings.

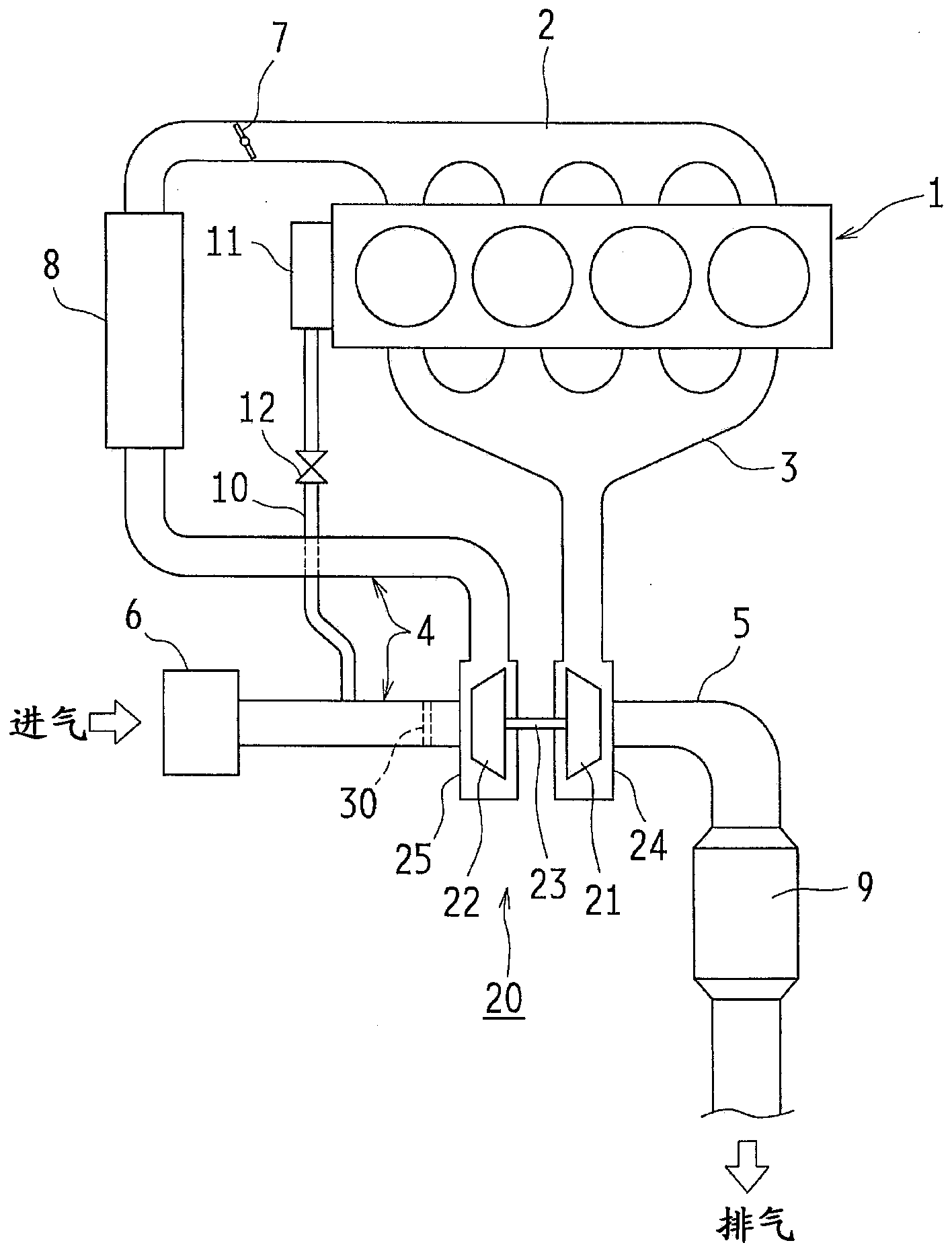

[0038] Figure 1 to Figure 3 One embodiment of the present invention is shown. The engine 1 illustrated in this embodiment is, for example, an inline four-cylinder. An intake manifold 2 for distributing and supplying intake air to each cylinder and an exhaust manifold 3 for collecting exhaust gas discharged from each cylinder are attached to a cylinder head (not shown) of the engine 1 .

[0039] An intake pipe 4 for taking in air from the atmosphere is connected to the intake manifold 2 . An air cleaner 6 is installed at the inlet of the intake pipe 4 . The intake manifold 2 and the intake pipe 4 constitute an intake passage.

[0040] In addition, a throttle valve 7 for adjusting the intake air amount of the engine 1 is provided on the intake manifold 2 on the upstream side in the flow direction of intake air. The throttle valve 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com