Cold rolling strip steel plate shape dynamic variable gain control method

A control method and strip-steel shape technology, applied in contour control and other directions, can solve the problems of difficult to obtain satisfactory control effect, unsatisfactory control effect, etc. awesome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

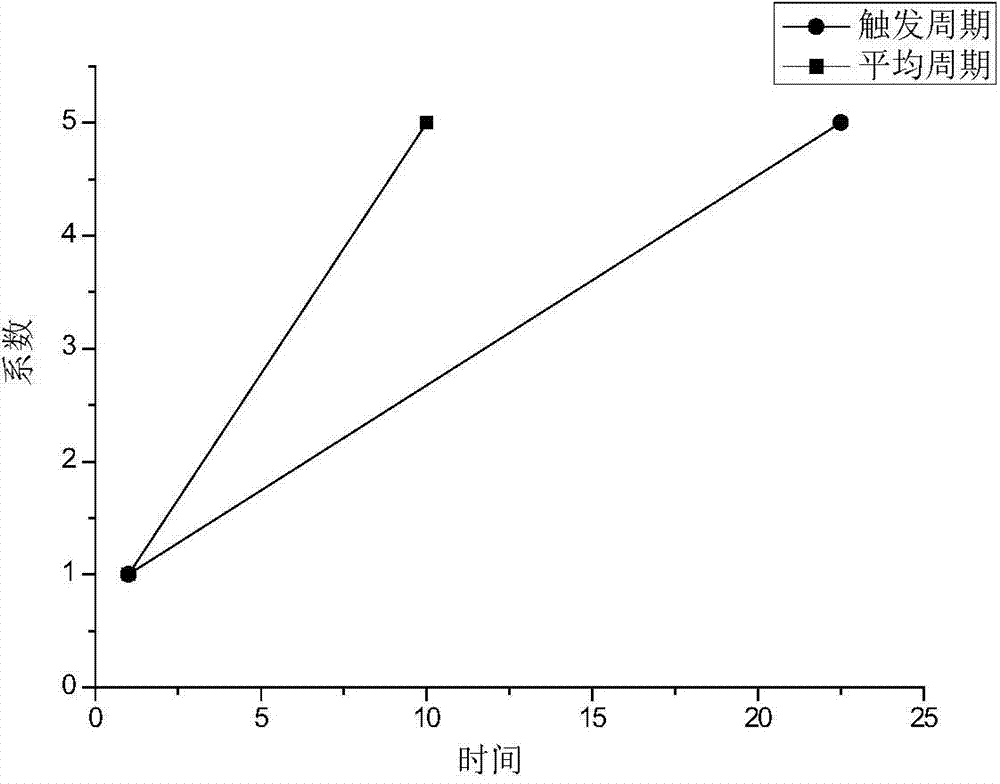

[0061] Step 1 Calculation of speed gain coefficient:

[0062] The speed gain is calculated, and the lag time is determined according to the trigger cycle of the shape measurement roller.

[0063] τ = l 2 πR

[0064] Values of control parameters: R is the radius of the shape measuring roll, which is 0.175m; l—the distance between the shape meter and the exit of the rolling mill, which is 4m.

[0065] The speed gain factor is:

[0066] kp _ v [ n ] = k _ fact [ n ] × t _ trig × t _ cycle t _ delay [ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com