Preparation method of high thermal conductivity natural flexible graphite film

A flexible graphite, high thermal conductivity technology, applied in the direction of chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of corrosion and residue of contact parts, and achieve the effect of poor high temperature oxidation resistance and low tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

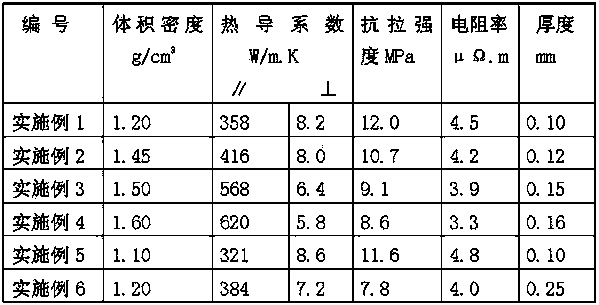

Examples

Embodiment 1

[0017] HClO 4 : HNO 3 : The natural flake graphite is mixed according to the weight ratio of 65:5:30. During the mixing process, the HClO 4 Pour into HNO 3 In a container, then the natural flake graphite is added in the above-mentioned mixed acid and stirred for 1.5min. The above natural flake graphite has an average particle size of 32 meshes, a carbon content of 99.95wt.%, the concentration of nitric acid used is 65wt.%, and the concentration of perchloric acid is 70wt.%. The stirred mixture was heated to 60° C. and reacted at this temperature for 10 min to obtain a perchloric acid / graphite intercalation compound. The resulting perchloric acid / graphite intercalation compound was then washed with deionized water to a pH of 5.8. Put the laundry into a drying oven, heat it to 80°C for drying treatment, and the drying time is 4 hours. After drying, take it out of the furnace and cool it down to room temperature naturally, then put the dried material into a high-temperature...

Embodiment 2

[0019] HClO 4 、HNO 3 It is mixed with natural flake graphite according to the weight ratio of 62.5:3.5:34. During the mixing process, the HClO 4 Pour into HNO 3 In the container, then join natural flake graphite in the above-mentioned mixed acid and stir 2min. The above natural flake graphite has an average particle size of 40 meshes, a carbon content of 99.98wt.%, the concentration of nitric acid used is 66wt.%, and the concentration of perchloric acid is 71wt.%. The stirred mixture was heated to 50° C., and reacted at this temperature for 20 min to obtain a perchloric acid / graphite intercalation compound. The resulting perchloric acid / graphite intercalation compound was then washed with deionized water to a pH of 6.0. Put the laundry into a drying oven, heat it to 90°C for drying treatment, and the drying time is 3 hours. After drying, take it out of the furnace and cool it down to room temperature naturally, then put the dried product into a high-temperature puffing f...

Embodiment 3

[0021] HClO 4 、HNO 3 It is mixed with natural flake graphite according to the weight ratio of 65:2:33. During the mixing process, the HClO 4 Pour into HNO 3 In the container, then join natural flake graphite in the above-mentioned mixed acid and stir 3min. The above natural flake graphite has an average particle size of 32 meshes, a carbon content of 99.92wt.%, the concentration of nitric acid used is 67wt.%, and the concentration of perchloric acid is 70wt.%. The stirred mixture was heated to 70° C., and reacted at this temperature for 30 minutes to obtain a perchloric acid / graphite intercalation compound. The resulting perchloric acid / graphite intercalation compound was then washed with deionized water to a pH of 6.5. Put the laundry into a drying oven, heat it to 95°C for drying treatment, and the drying time is 2 hours. After drying, take it out of the oven and cool it down to room temperature naturally, then put the dried product into a high-temperature expansion fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com