Wax for self-healing metalized capacitor

A metallized capacitor, self-healing technology, applied in the field of potting materials, can solve the problems of reducing wax shrinkage, unable to eliminate the shrinkage and swelling of solid wax, and unable to solve the problem of swelling and leakage of polypropylene film, etc., to achieve low temperature shrinkage small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

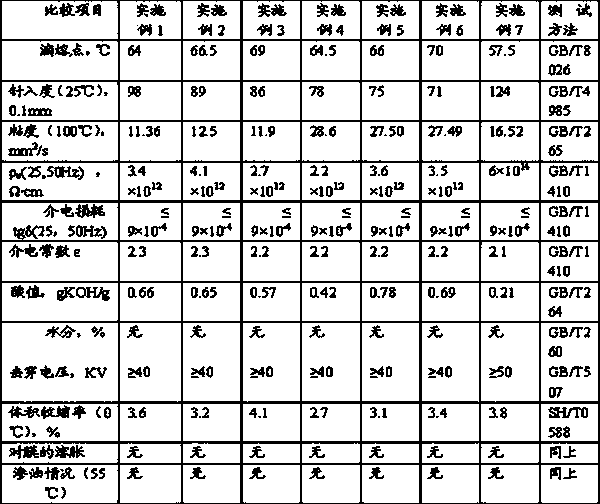

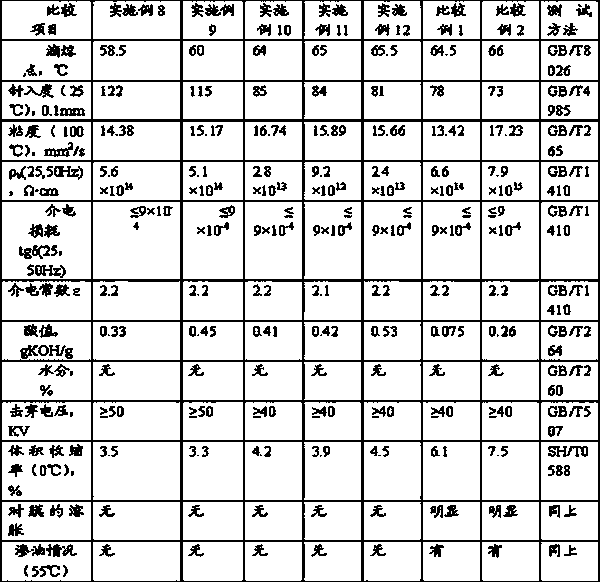

Examples

Embodiment 1

[0052] Step (1), pre-melt 10 parts of microcrystalline wax, add 0.1 part of hydrogenated styrene-butadiene rubber, control the temperature at 120±5°C, stir for 60 min, and the stirring speed is 60 r / min;

[0053] Step (2), add 4.9 parts of hydroxyl-terminated polybutadiene, control the temperature at 100±5°C, stir for 60 min, and the stirring speed is 60 r / min;

[0054] Step (3), add 5 parts of oil-gelling agent, control the temperature not lower than 90°C, stir for 60 min, and the stirring speed is 60 r / min;

[0055] Step (4), finally add 80 parts of vegetable oil slowly, control the temperature not lower than 90°C, stir for 60 min, and the stirring speed is 60 r / min;

[0056] Step (5), discharging, cooling and molding to obtain the wax for self-healing metallized capacitors.

Embodiment 2

[0058] Step (1), pre-melt 20 parts of microcrystalline wax, add 0.1 part of hydrogenated styrene-butadiene rubber, control the temperature at 120±5°C, stir for 70 min, and the stirring speed is 60 r / min;

[0059] Step (2), add 4.9 parts of hydroxyl-terminated polybutadiene, control the temperature at 100±5°C, stir for 70 min, and the stirring speed is 60 r / min;

[0060] Step (3), add 5 parts of oil-gelling agent, control the temperature not lower than 90°C, stir for 60 min, and the stirring speed is 60 r / min;

[0061] Step (4), finally slowly add 70 parts of vegetable oil, control the temperature not lower than 90°C, stir for 70 min, and the stirring speed is 60 r / min;

[0062] Step (5), discharging, cooling and molding to obtain the wax for self-healing metallized capacitors.

Embodiment 3

[0064] Step (1), pre-melt 30 parts of microcrystalline wax, add 0.1 part of hydrogenated styrene-butadiene rubber, control the temperature at 120±5°C, stir for 80 min, and the stirring speed is 60 r / min;

[0065] Step (2), add 4.9 parts of hydroxyl-terminated polybutadiene, control the temperature at 100±5°C, stir for 80 min, and the stirring speed is 60 r / min;

[0066] Step (3), add 5 parts of oil-gelling agent, control the temperature not lower than 90°C, stir for 60 min, and the stirring speed is 60 r / min;

[0067] Step (4), finally slowly add 60 parts of vegetable oil, control the temperature not lower than 90°C, stir for 60 min, and the stirring speed is 60 r / min;

[0068] Step (5), discharging, cooling and molding to obtain the wax for self-healing metallized capacitors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com