Self-healing latex cementing cement slurry and its preparation and application

A cementing slurry, self-healing technology, applied in wellbore/well components, drilling composition, earth-moving drilling, etc., can solve the problem of lack of self-healing ability, improvement of the integrity and durability of cementing cement sheath It has limited effect and cannot meet the requirements of anti-gas channeling, anti-corrosion and anti-damage of complex wells and gas storage wells, and achieves the effect of good performance and good self-healing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

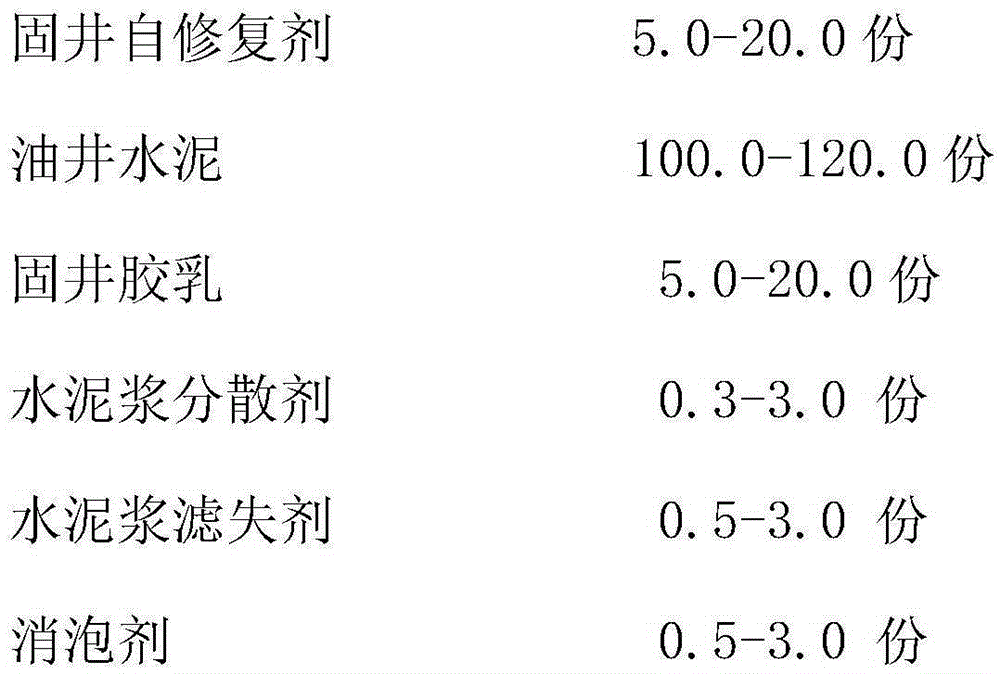

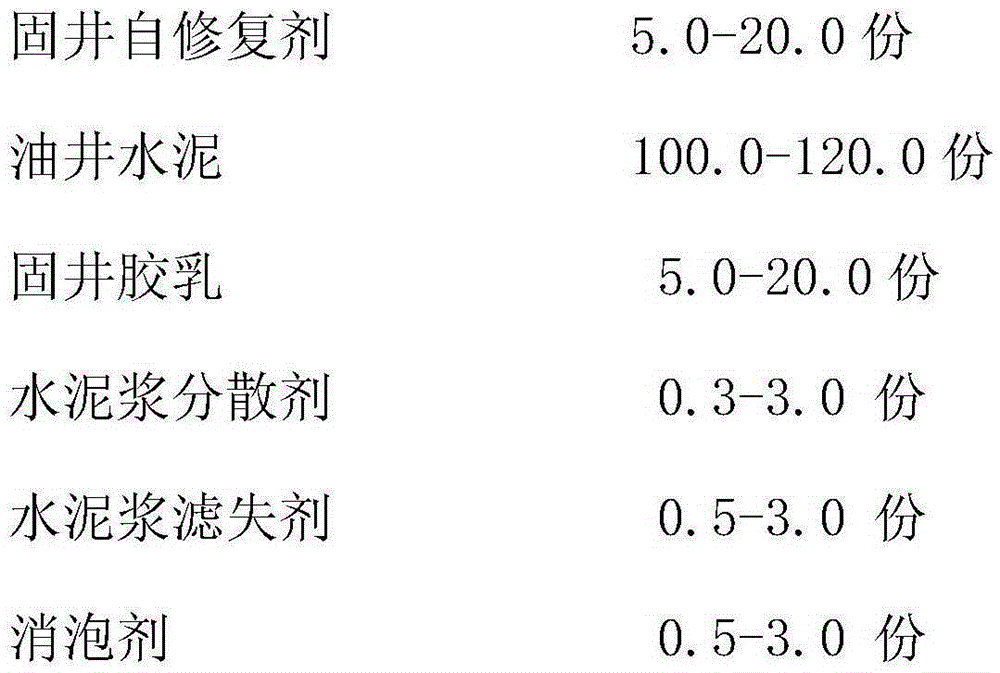

[0041] A self-healing latex cementing cement slurry system consists of the following components (parts by weight):

[0042]Rare earth coordination type oil and gas well cementing cement sheath self-repair agent (self-made) 10 parts; oil well cement (product grade: G grade, product source: Sichuan Jiahua Cement Co., Ltd.) 100 parts; cementing latex (product code: JR , product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 6 parts; cement slurry dispersant (product code: SXY-2, product source: Chengdu Chuanfeng Chemical Engineering Co., Ltd.) 1.6 parts; cement slurry fluid loss agent ( Product code: BS100-2, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 1 part; cement slurry fluid loss agent (product code: BS100, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 1 part; 0.5 parts of defoamer (product code: BP-1B, product source: Chongqing Ho...

Embodiment 2

[0053] A self-healing latex cementing cement slurry system consists of the following components (parts by weight):

[0054] Rare earth coordination type oil and gas well cementing cement sheath self-repair agent (self-made) 15 parts; oil well cement (product grade: G grade, product source: Sichuan Jiahua Cement Co., Ltd.) 100 parts; cementing latex (product code: JR , product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 10 parts; cement slurry dispersant (product code: SXY-2, product source: Chengdu Chuanfeng Chemical Engineering Co., Ltd.) 1.6 parts; cement slurry fluid loss agent ( Product code: BS100-2, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 1 part; cement slurry fluid loss agent (product code: BS100, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 1 part; 0.5 parts of defoamer (product code: BP-1B, product source: Chongqing ...

Embodiment 3

[0058] A self-healing latex cementing cement slurry system consists of the following components (parts by weight):

[0059] 10 parts of cement-based permeable crystalline waterproof material masterbatch (CCCW); 100 parts of oil well cement (product grade: G grade, product source: Sichuan Jiahua Cement Co., Ltd.); cementing latex (product code: JR, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 10 parts; cement slurry dispersant (product code: SXY-2, product source: Chengdu Chuanfeng Chemical Engineering Co., Ltd.) 1.6 parts; cement slurry fluid loss agent (product code: BS100 -2, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 1 part; cement slurry fluid loss agent (product code: BS100, product source: Chongqing Hongsheng Oil and Gas Field Exploitation Technology Service Co., Ltd.) 1 part; defoamer ( Product code: BP-1B, product source: Chongqing Hongsheng Oil and Gas Field Explo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com