Method for preparing aromatic plant essential oil by using subcritical CO2 fluid extraction technology

An extraction technology, a technology of aromatic plants, applied in the field of preparation of essential oils, can solve problems such as lack of systematic research on fluid technology, lack of attention, and loss of "top aroma"

Inactive Publication Date: 2014-01-29

符波 +2

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the common method of producing these two essential oils is still the steam distillation method, which has the disadvantages of loss of "top aroma" and easy oxidation of heat-sensitive substances.

Subcritical CO 2 The application of fluid technology has not been paid attention to due to the lack of systematic research

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0016] Examples 2-5: The ratios of ethanol-ethyl acetate mixed solvent in Example 1 are respectively: 1:0, 1:1, 1:9, 0:1.

Embodiment 2~5

[0017] Embodiment 6: In embodiment 1, add 3.0% (weight ratio) ethanol-ethyl acetate mixed solvent (9: 1) in extractor.

Embodiment 6

[0018] Example 7: The extraction time in Example 1 was increased to 5 hours.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

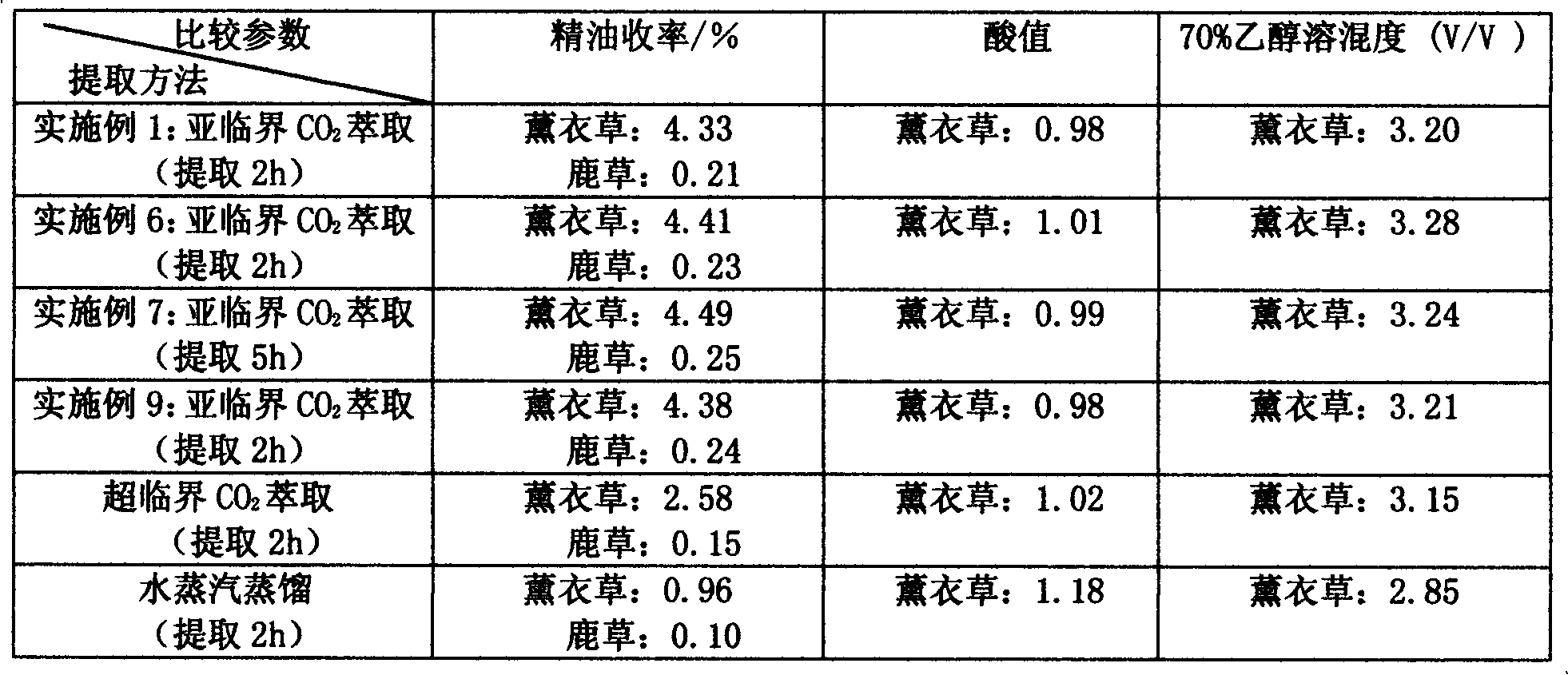

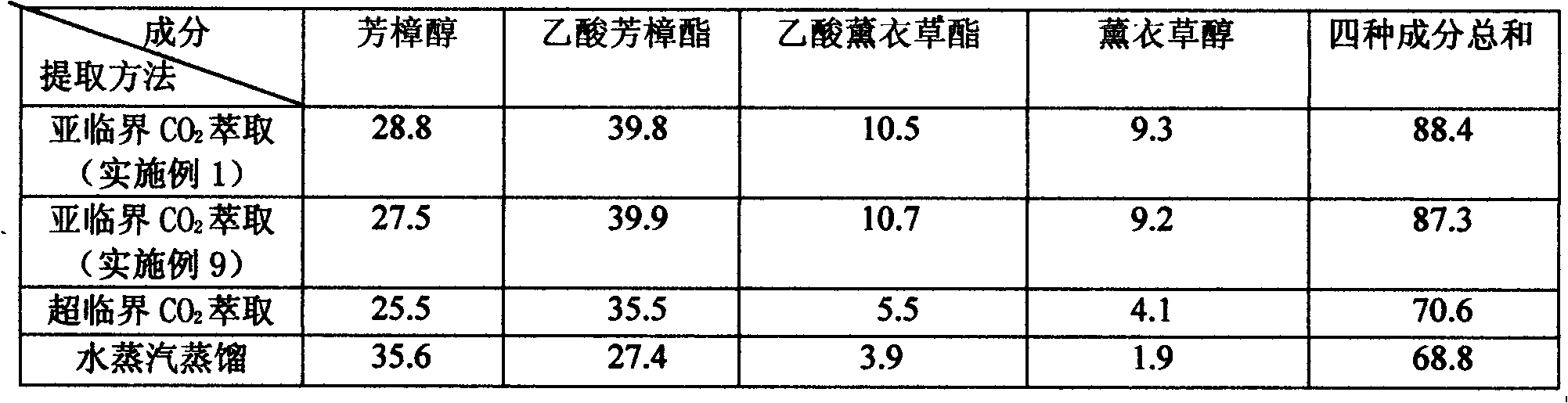

The invention relates to a method for preparing aromatic plant essential oil by using a subcritical CO2 fluid extraction technology. The method is characterized in that 0.5-5% of polar solvent is added to subcritical CO2 fluid (40 DEG C, 250 bar) so as to serve as a carrying agent, so that the formed subcritical CO2 fluid extraction technology realizes the preparation of the essential oil under the conditions of room temperature and low pressure (20-30 DEG C, 100-200 bar), the product is high in yield and has good quality, wherein the essential oil prepared by the subcritical CO2 fluid extraction technology preferably using an ethyl alcohol and ethyl acetate mixed solvent as the carrying agent has the advantages that the extraction rate of SFE (Supercrtical Fluid Extraction) lavender essential oil can be increased from 2.58% to 4.33% and the extraction rate of SFE rhaponticum carthamoides essential oil can be increased from 0.15% to 0.21%. The total content of the four marking components (linalyl acetate, lavandayl acetate and lavandulol) in the Sinkiang lavender essential oil is increased and reaches above 87%.

Description

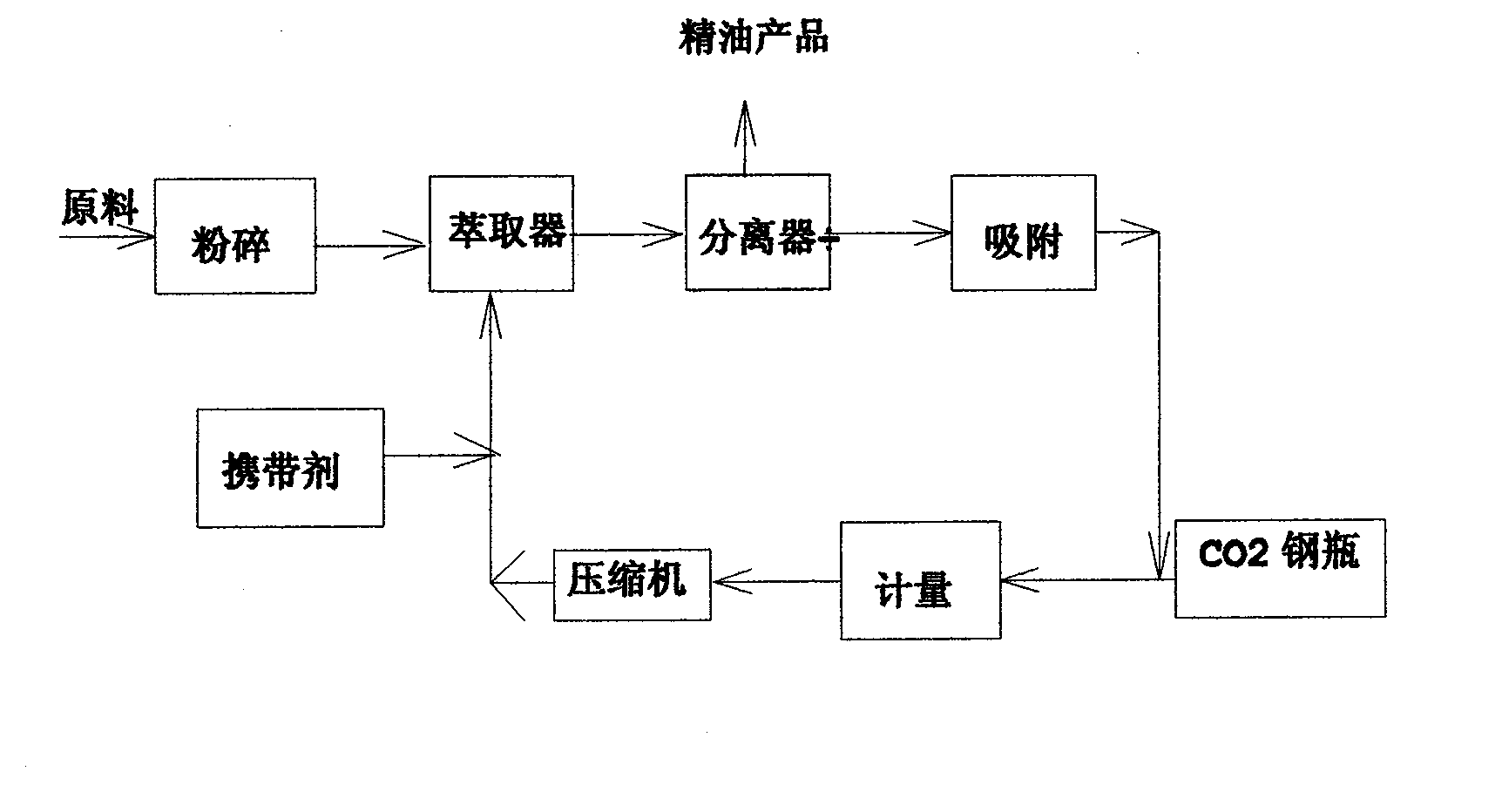

technical field [0001] The present invention relates to a kind of using subcritical CO 2 Fluid extraction technology is a method for preparing essential oil from aromatic plants Lamiaceae Lavender and Asteraceae Lavender as raw materials. Background technique [0002] Aromatic plant essential oils have been widely used in medicine, smoked tea, cosmetics, washing, food and other industries in recent years due to their unique aroma and physiological activity. Western countries have long been committed to the extraction of aromatic plant essential oils. To this day, many methods of extracting essential oils have been formed. Extracting essential oils from aromatic plants has been followed by steam distillation, pressing and organic solvent extraction. The steam distillation method needs to heat the raw materials, which is not suitable for the extraction of chemically unstable components; the yield of the squeezing method is low; the organic solvent extraction method will cau...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C11B9/02

Inventor 符波唐卿唐凯王力

Owner 符波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com