High-frequency quenching process of n-type collision pin

A high-frequency quenching and process technology, applied in the field of high-frequency quenching, can solve problems such as ∏-shaped knock pin cracks, easy to break, and easy to cause traffic accidents, and achieve the effects of improving efficiency, improving safety performance, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

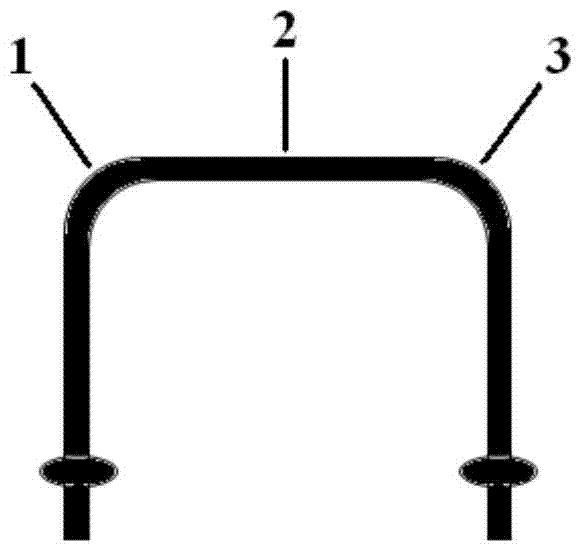

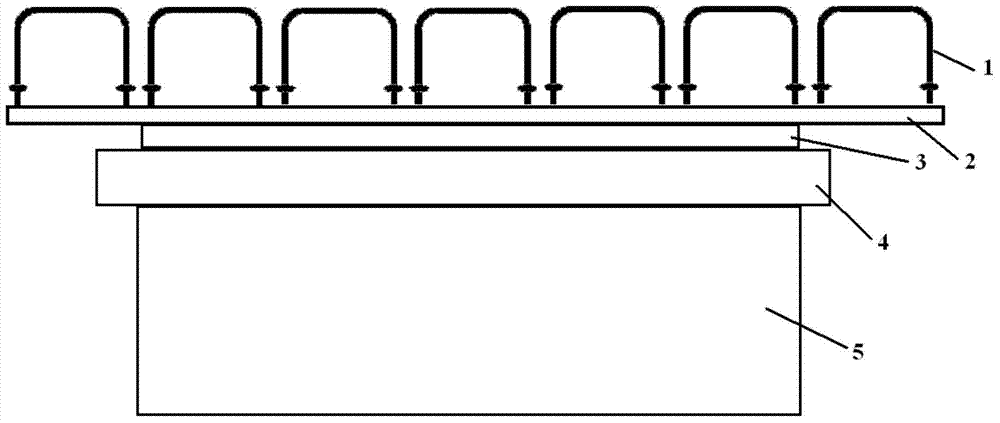

[0011] The production equipment model of the present invention is GGC80-2A for high-frequency quenching of ∏-shaped striker pins, the frequency is 250kHz, and the process flow is: placement→heating→oil quenching→tempering. Placement: Up to 7 parts can be placed on the quenching machine for high-frequency quenching at the same time. The schematic diagram of placement is as follows figure 2 shown. Heating: The temperature is 880-900°C, the ascent speed of the quenching machine is 125mm / min, the cathode voltage is 7.5kV, the anode current is 5A, and the grid current is 0.5A. When the sensor rises to the two fillets, it stays for 0.1s. To ensure even heating when heated to this place. Oil Quenching: Cool the heated parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com