Preparation method of laser cladding forming composite material enhanced by nano materials

A nanomaterial and composite material technology, applied in the field of laser cladding forming composite material manufacturing, can solve the problems of poor fatigue and fracture properties, prone to cracks, and insufficient compactness inside the forming material, so as to shorten the manufacturing time, improve the efficiency, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

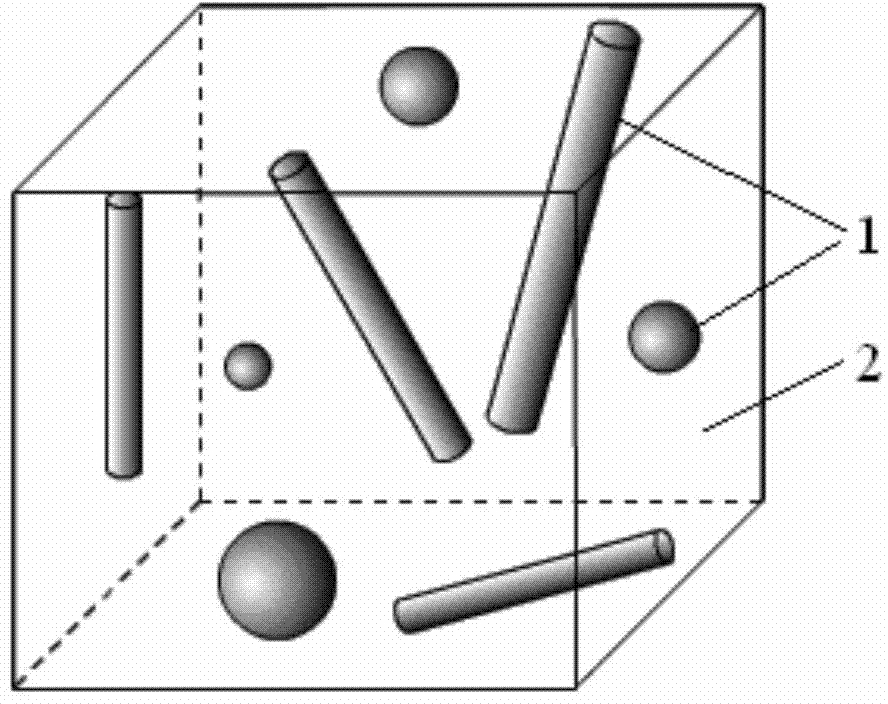

[0074] 1. Geometric description:

[0075] Composite material is 1 cube.

[0076] 2. The specific implementation method:

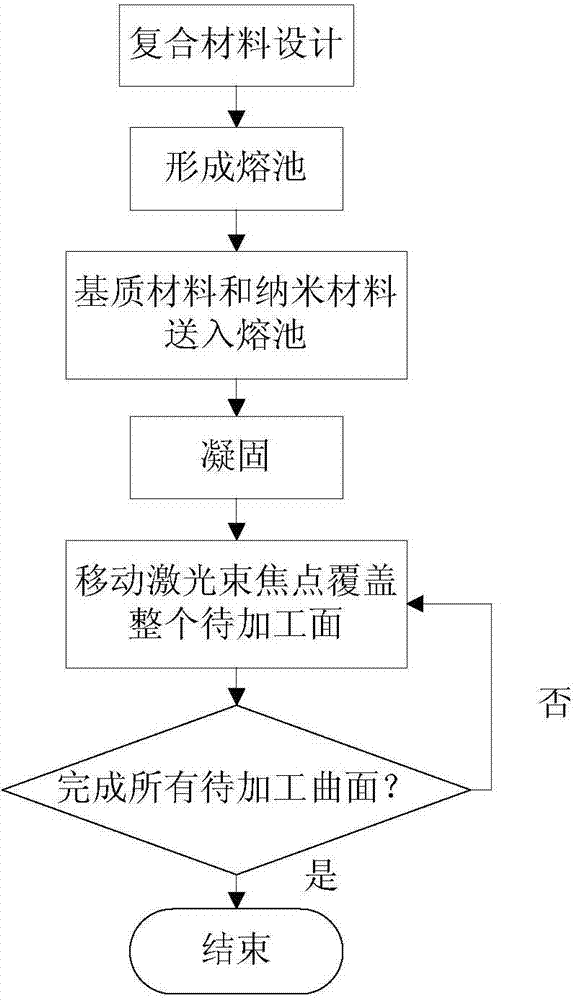

[0077] (1) Design the required composite material structure and decompose it into a series of curved surfaces with thickness to be processed;

[0078] Use CAD software to build a 10mm×10mm×10mm cube. In the cube, the matrix material is AerMet100 steel powder, and its chemical composition (mass fraction, %) is 13.47Co, 11.38Ni, 2.96Cr, 1.23Mo, 0.23C, 0.048Si, 0.014Mn, 0.0074Al, 0.0007S, < 0.005P, <0.005Ti, 0.0028O, Fe balance. The nanomaterials are football ene nanoparticles, which are evenly distributed. A right-handed rectangular coordinate system o-xyz is established with a vertex of the cube as the coordinate origin and three edges starting from the vertex as coordinate axes, and the cube is decomposed into 10 planes to be processed parallel to the xy plane, and the thickness of each plane 1mm, length and width are 10mm and 10mm respectively;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com