High temperature plugging and regulating equipment and high temperature blocking and regulating method for steam flooding in super heavy oil reservoirs

A super-heavy oil and steam flooding technology, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problem of high requirements for construction technology and reservoir cognition, permanent pollution of oil layers, and lack of options In order to achieve the effect of prolonging the effective period of blocking adjustment, reducing interfacial tension and reducing engineering risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

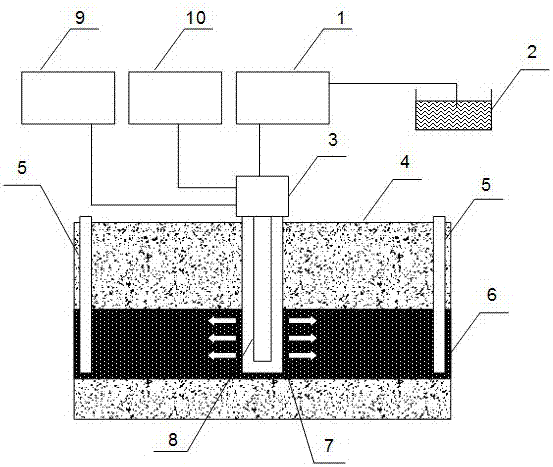

[0038] like figure 1 as shown, figure 1 It is a structural diagram of high-temperature blockage and adjustment equipment for steam flooding of super-heavy oil reservoirs of the present invention. The high-temperature blockage and adjustment equipment for steam flooding in super-heavy oil reservoirs consists of injection equipment 1, liquid distribution pool 2, thermal recovery steam injection wellhead 3, casing 7, heat-insulated tubing 8, nitrogen injection equipment 9 and steam injection equipment 10. Injection equipment 1 is located in the high-temperature and high-pressure area of the well site of the steam drive well, and is connected to the small four-way port 3 of the thermal recovery steam injection wellhead 3, and is used to inject gel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com