Mass flow meter based detection method for remaining ammonia amount of solid ammonia storage system

A technology of mass flowmeter and detection method, which is applied in the direction of exhaust gas treatment, electrical components, and electric control of exhaust gas treatment devices, etc., which can solve the problems of reduced NH3 adsorption, low adsorption and desorption efficiency, and affecting the use effect, etc. Achieve effects that are conducive to emission reduction, high practical value, reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Prepare a stainless steel pressure-resistant storage tank with an effective volume of 32L, fill 15kg of solid ammonia storage material into the storage tank, and complete the ammonia filling, weighing system, the ammonia filling volume is 14.7kg; purchase commercially available pressure sensors, temperature sensors and Ammonia gas mass flowmeter, purchase the display controller with built-in PID control program, according to the analog parameter of the flowmeter used is the voltage of 0~5V, when the flow rate of ammonia gas is 0L / min, the corresponding analog parameter is 0V, when When the flow rate of ammonia gas is 20L / min, the corresponding analog parameter is 5V, and the calculation program of a) b) c) three flow accumulations are programmed into the board of the display controller, and the green lights corresponding to the three states, Yellow light and red light display table; complete the wiring and connection between the above units; connect the antifreeze heatin...

Embodiment 2

[0024] Using the ammonia storage and release ammonia control metering system prepared in Example 1, start the mass flow meter and the display controller, continue heating and releasing ammonia, the ammonia flow rate is 5SLP (that is, standard liters per minute), and when the ammonia release time is 0min, the display The controller displays a green light; when the ammonia release time is 3326 minutes, the green light turns into a yellow light. At this time, the cumulative amount of ammonia released by the mass flowmeter is 12.64kg; the control accuracy is within the required range.

Embodiment 3

[0026] Continue to adopt the ammonia storage and release ammonia control metering system tested in Example 2, continue to carry out continuous heating and release ammonia, and the ammonia gas flow rate is 5SLP. When the ammonia release time is 3719 minutes, the display controller displays a red light; at this time, the cumulative amount of ammonia release by the mass flowmeter is 14.13kg;

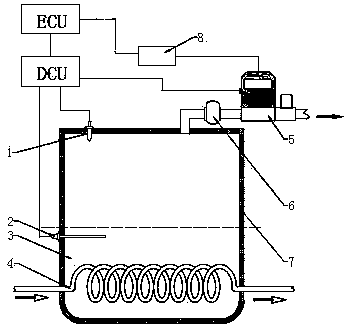

[0027] In the relevant inventions that have been given, for the pressure sensor 1, the temperature sensor 2, the solid ammonia storage material 3, the antifreeze conduit 4, the ammonia gas inlet and outlet 6 and the ammonia storage tank 7 have been described; the innovation of the present invention is Introduced the combined control and metering method of ammonia gas mass flow meter 5 and display controller 8;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com