Frictional infinitely variable speed device with double-intermediate-roller steering reducing mechanism

A continuously variable speed change mechanism, roller technology, applied in electromechanical devices, transmission devices, mechanical equipment, etc., can solve the problems of affecting transmission efficiency, low bearing capacity, large friction coefficient, etc., and achieve easy operation, low friction resistance, and low wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

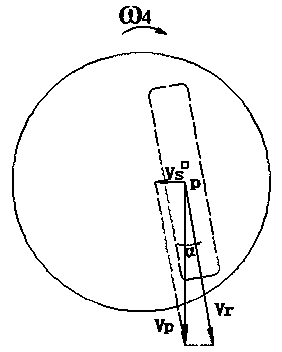

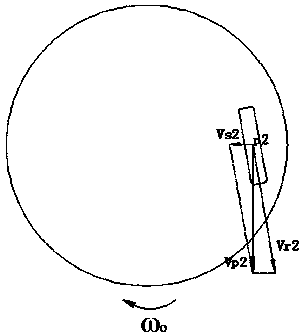

Method used

Image

Examples

Embodiment Construction

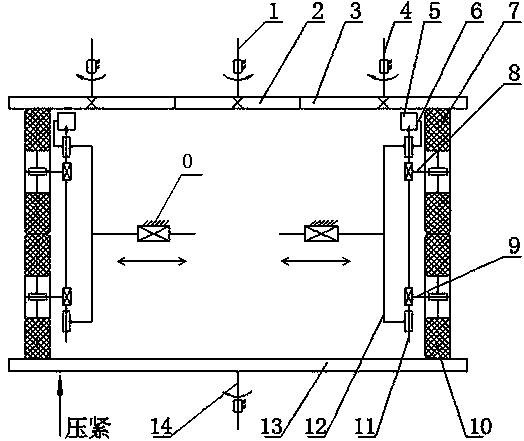

[0032] Please refer to the accompanying drawings for a further description of the present invention.

[0033] Such as figure 1 As shown, the present invention provides a friction type continuously variable transmission device with a double intermediate roller steering diameter reducing mechanism, including an input shaft 1, an input shaft gear 2, an input friction disc 3, an intermediate shaft 4, a small motor 5, and a motor base 6. The first intermediate roller 7, the first roller shaft 8, the second roller shaft 9, the second intermediate roller 10, the main pin 11, the reducing bracket 12, the output friction disc 13 and the output shaft 14.

[0034] The specific motion sub-relationships are as follows:

[0035]The input shaft gear 2 is fixedly connected to the input shaft 1, there is no relative movement between the two, the input shaft 1 is connected with the rotating pair of the frame 0, the input shaft gear 2 and the input shaft 1 can only rotate around the axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com