Detection and quality judgment method for strip steel weld surface appearance

A surface topography, strip weld technology, applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of inaccurate judgment, lack of test result analysis function, and inability to judge the fracture resistance of welds Edge defects and other problems to achieve the effect of preventing broken belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

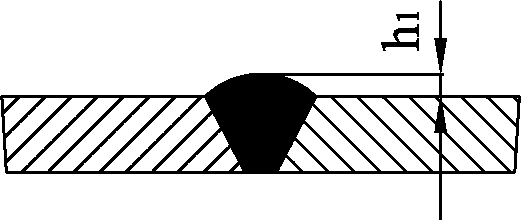

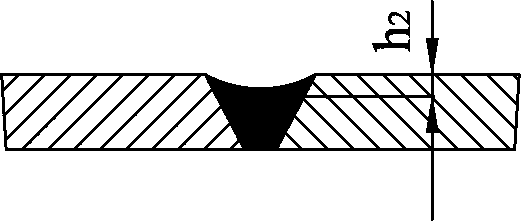

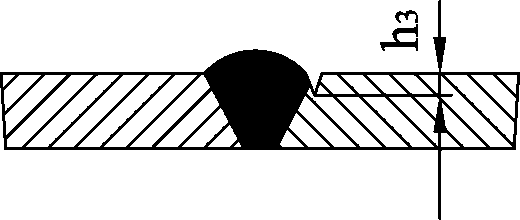

Image

Examples

Embodiment 1

[0047] Rolling process of automotive sheet in cold rolling line.

[0048] 1) The weld detection system consists of a laser, a trigger switch, an upper industrial computer and a lower PC. The laser, trigger switch, and upper industrial computer are fixed on the welding machine and move with the welding machine during the detection process. The lower PC is placed In the operating room, a weld evaluation system is installed in the lower computer.

[0049] 2) The linear laser adopts CC3000-30 from American Bytewise Company to complete the scanning of the weld seam shape. The scanning width range is 10mm, the height detection range is 30mm, and the detection accuracy is 0.015mm. The detected data are sent to the upper industrial computer in real time , The detection frequency is 30HZ. The upper industrial computer is responsible for the collection and processing of signals, filters the data collected by the laser, collects the data within the range of 3mm (10mm in total) on both s...

Embodiment 2

[0058] The composition of the system is the same as that of Example 1. For low-grade silicon steel, due to the high brittleness of the material, the evaluation index needs to be adjusted. The adjusted index is shown in Table 2. Using this index to evaluate low-grade silicon steel welds can control the broken belt rate below 1‰.

[0059] Table 2 Evaluation indicators for low-grade silicon steel

[0060] serial number

Embodiment 3

[0062] The composition of the system is the same as in Example 1. For medium-grade silicon steel, due to the high silicon content in the material and the high brittleness of the material, it is necessary to strictly limit the defect threshold. The adjusted indicators are shown in Table 3. Using this index to evaluate the weld seam of medium-grade silicon steel can control the broken belt rate below 1‰.

[0063] Table 3 Evaluation indicators for low-grade silicon steel

[0064] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com