Automatic removing method of vehicle-mounted laser point cloud noisy point based on angle and intensity

A vehicle-mounted laser and intensity technology, applied in the field of photogrammetry and 3D laser, can solve the problems of large workload, easy filtering, low efficiency, etc., and achieve the effect of high degree of automation, high processing efficiency, simple and effective operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

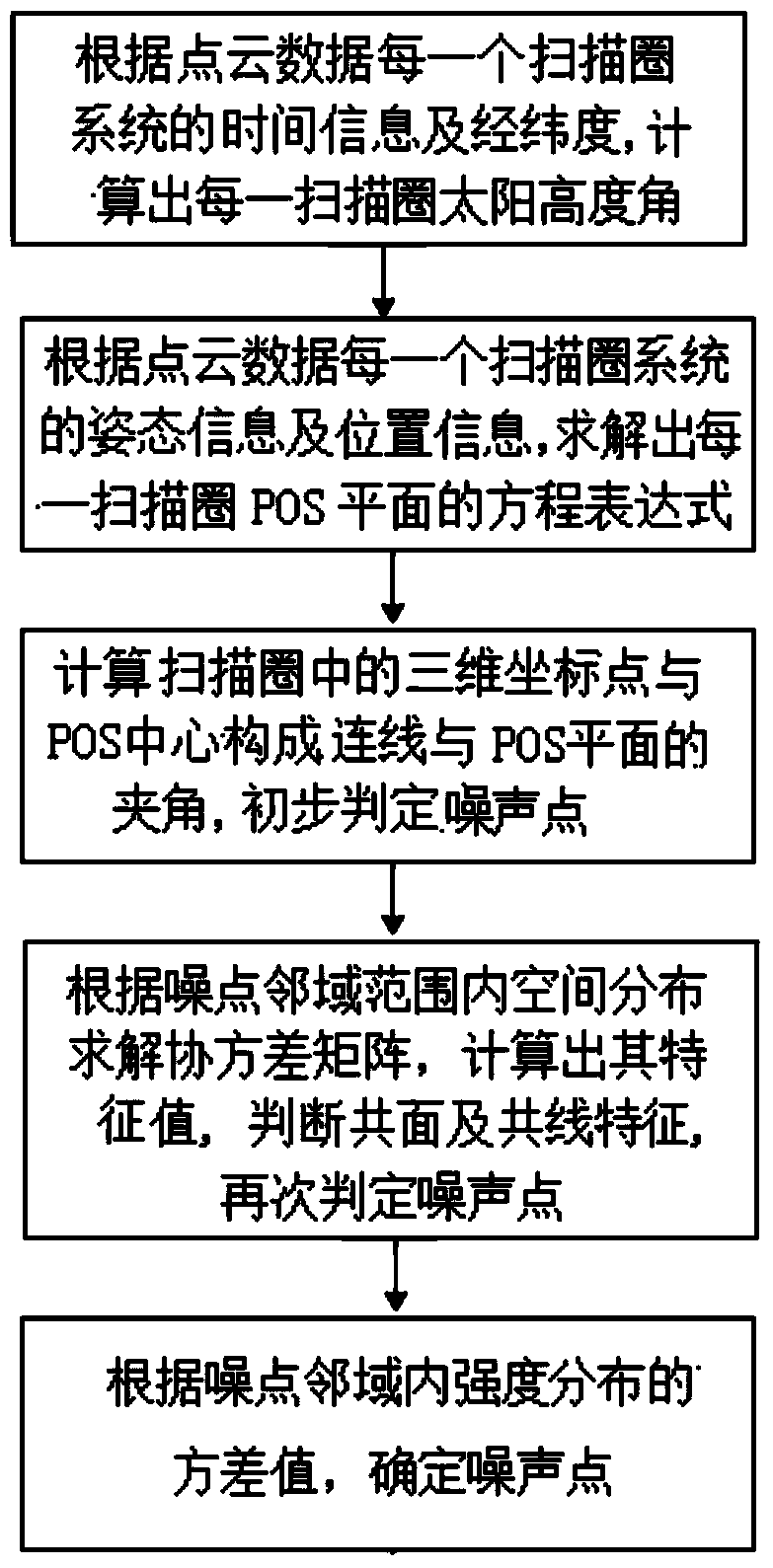

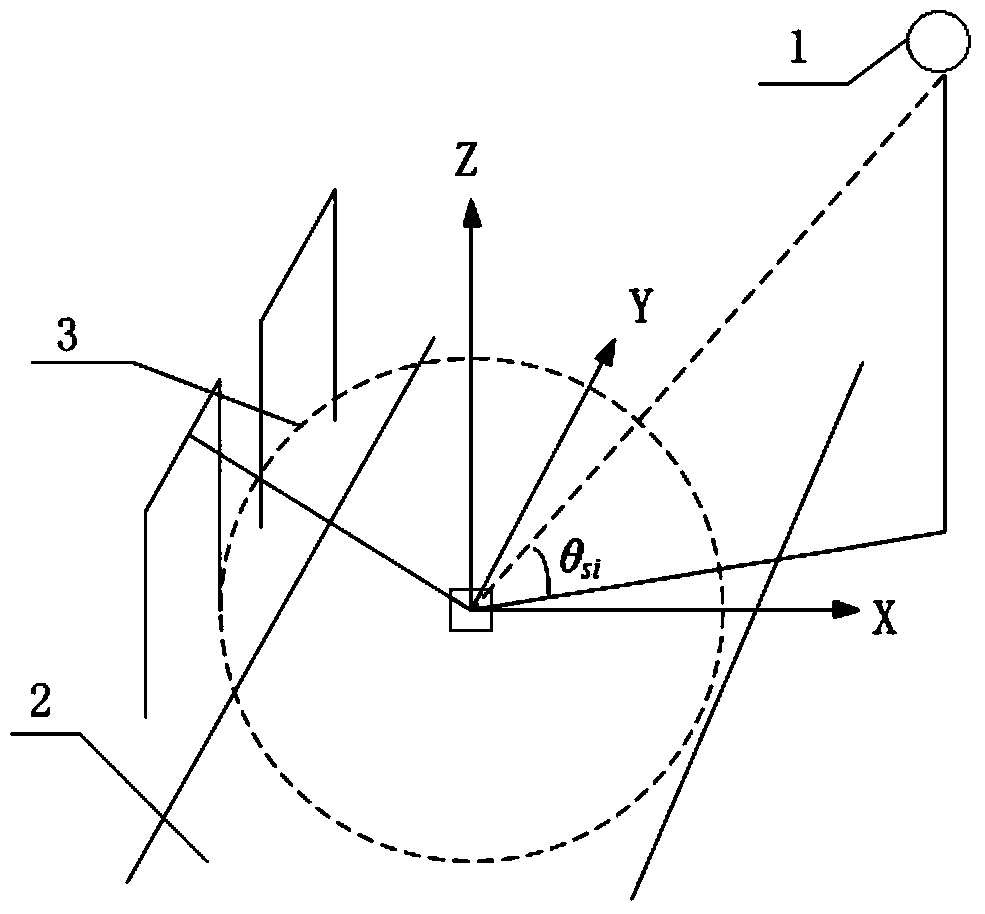

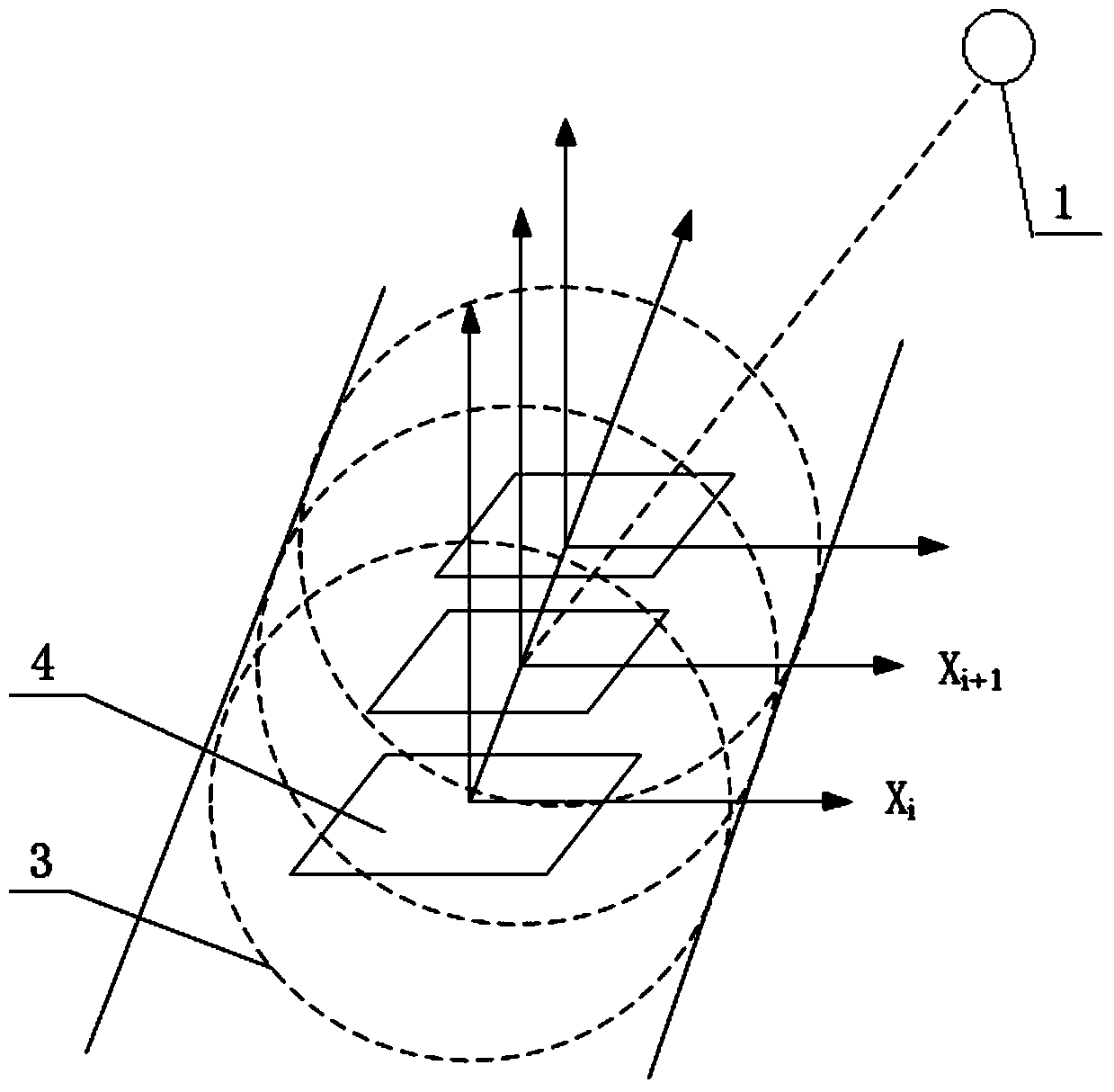

[0034] Embodiment 1: A kind of vehicle-mounted laser point cloud noise automatic removal method based on angle and intensity proposed by the present invention, its operation steps are as follows figure 1 shown. The specific operation is: first, use the vehicle-mounted 3D laser measurement system to collect data. The integrated components of the vehicle-mounted 3D laser mobile measurement system include vehicles, 3D laser scanners, GPS navigators, inertial guidance systems and panoramic cameras. The 3D laser scanner is used to obtain point cloud data, and the POS system composed of GPS navigator and inertial guidance system is used to obtain attitude and position information; the point cloud data is organized according to the circle index to obtain the 3D coordinates of each scanning circle Point set; according to the time alignment, according to the interpolation settlement of the collected POS information, the posture information and position information of each circle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com