Processed cheese and preparation method thereof

A technology for processed cheese and natural cheese, which is applied in cheese substitutes, dairy products, applications, etc., can solve the problems of poor thermal stability, softening and melting, and structural damage of processed cheese, and achieves excellent texture properties and Taste, easy to operate, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

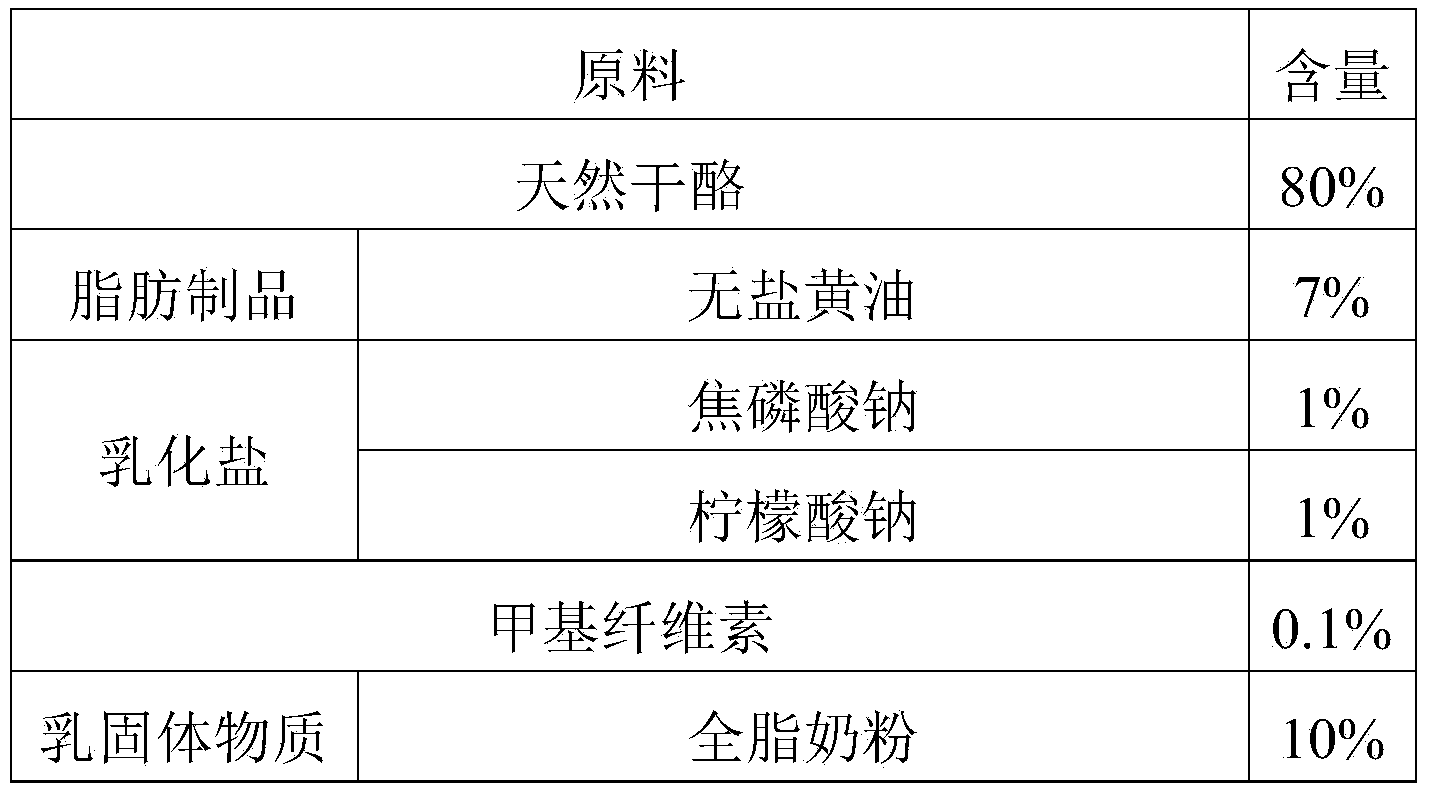

[0041] raw material:

[0042]

[0043]

[0044] Described percentage is the mass percentage that accounts for raw material;

[0045] The preparation method comprises the following steps:

[0046] (1) Mix the above-mentioned raw materials evenly, shear pre-mixing, the stirring speed of shearing pre-mixing is 1000rpm, and the temperature of shearing pre-mixing is 20°C; heat and stir, the temperature of heating and stirring is 85°C, and the stirring speed Be 800rpm, time is 5min; Obtain premix;

[0047] (2) Pasteurize the premix, the pasteurization temperature is 95°C, and the pasteurization time is 5s; stir emulsification, the stirring emulsification temperature is 90°C, the stirring speed is 600rpm, and the time is 5min, the end point of stirring and emulsification is until the viscosity of the obtained material is 4500pa / s; forming;

[0048] (3) Rapid cooling to -20°C within 20 minutes.

[0049] The main indexes of the prepared processed cheese are as follows: moistu...

Embodiment 2

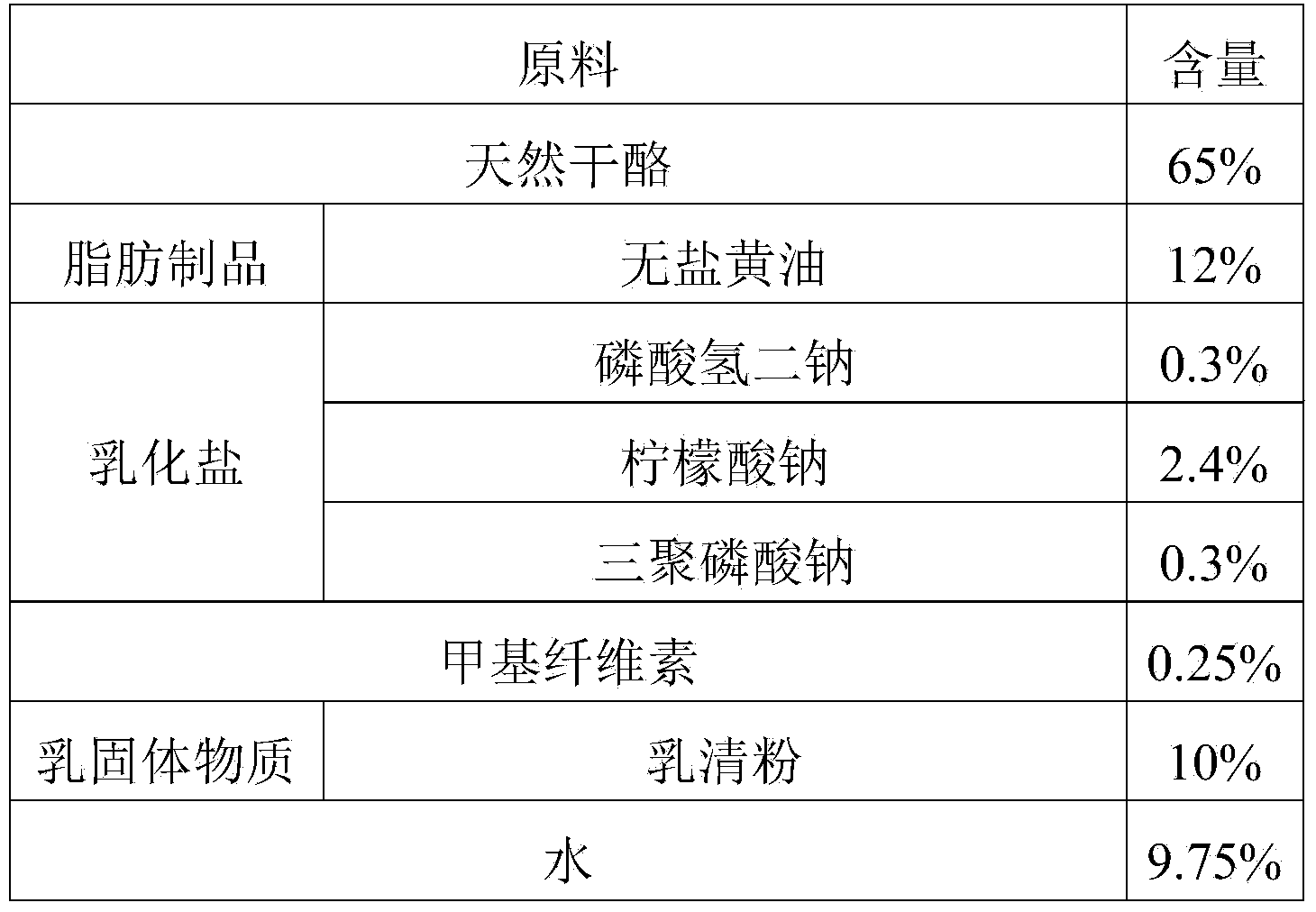

[0051] raw material:

[0052]

[0053] Described percentage is the mass percentage that accounts for raw material;

[0054] The preparation method comprises the following steps:

[0055] (1) Mix the above-mentioned raw materials evenly, shear pre-mixing, the stirring speed of shearing pre-mixing is 500rpm, and the temperature of shearing pre-mixing is 20°C; heating and stirring, the temperature of heating and stirring is 85°C; heating and stirring The stirring speed is 500rpm, and the heating and stirring time is 5min; the premix is obtained;

[0056] (2) Pasteurize the premix, the pasteurization temperature is 95°C, and the pasteurization time is 5s; stir emulsification, the stirring emulsification temperature is 90°C, the stirring speed is 600rpm, and the time is 5min, the end point of stirring and emulsification is until the viscosity of the obtained material is 4500pa / s; forming;

[0057] (3) Rapid cooling to -30°C within 20 minutes.

[0058] The main indexes of t...

Embodiment 3

[0060] raw material:

[0061]

[0062] The preparation method comprises the following steps:

[0063] (1) Mix the above-mentioned raw materials evenly, shear pre-mixing, the stirring speed of shearing pre-mixing is 1000rpm, and the temperature of shearing pre-mixing is 25°C; heat and stir, the temperature of heating and stirring is 85°C, and the stirring speed 500rpm, the time is 4min ~ 12min5min; get the premix;

[0064] (2) Pasteurize the premix, the pasteurization temperature is 95°C, and the pasteurization time is 5s; stir emulsification, the stirring emulsification temperature is 90°C, the stirring speed is 600rpm, and the time is 2min~10min5min, the end point of stirring and emulsification is until the viscosity of the obtained material is 4500pa / s; post-molding;

[0065] (3) Rapid cooling to -30°C within 20 minutes.

[0066] The main indexes of the prepared processed cheese are as follows: moisture 40%; fat 32.5%; protein 20.0%; pH=5.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com