Preparation method of cancrinite molecular sieve membrane catalyst

A molecular sieve and cancryptite technology, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as toxic equipment, increased process costs, and corrosion, and achieve strong adaptability, low cost, and The effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

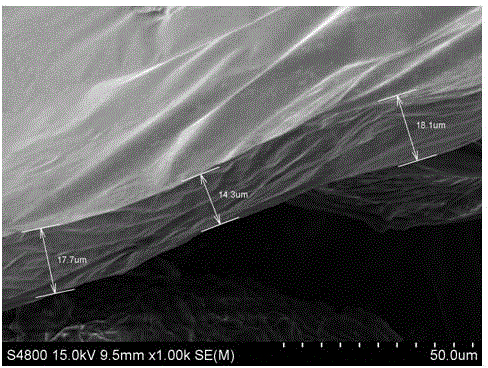

[0030] 1. Support body preparation: select ceramic Raschig rings as the support body, first polish the surface smooth, boil in NaOH solution for a period of time, and then ultrasonically rinse with deionized water.

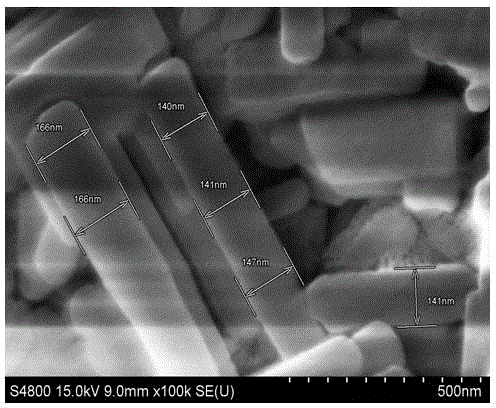

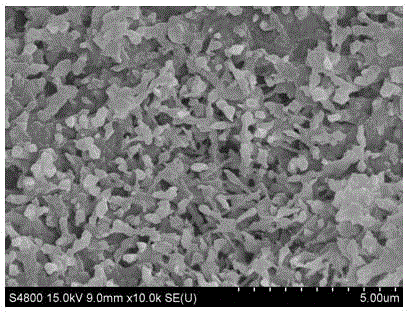

[0031] 2. Preparation of cancryptite molecular sieve crystal seeds: Weigh 6.0 g NaOH and dissolve it in 60.0 mL of deionized water, stir to dissolve it completely, add 3.0 g of sodium aluminate to the above NaOH solution and stir until completely dissolved, then Dissolve 52.0g of sodium silicate nonahydrate in the above mixture, stir for about 10-20min, and mix well. The above solution was transferred to a three-necked flask, stirred and reacted in a water bath at a constant temperature of 80 °C, and the pH value was adjusted to 14 with sulfuric acid, and the reaction was maintained for 3 hours. The obtained material was transferred into an autoclave and placed in a dry oven for crystallization at 170 °C for 3 h. The crystallized product was taken out, filtered, ...

Embodiment 2

[0044] 1. Preparation of the support body: select a glass sheet as the support body, first wash it with ethanol ultrasonically, then wash it with deionized water and then dry it.

[0045] 2. Preparation of cancryptite molecular sieve crystal seeds: Weigh 6.0 g NaOH and dissolve it in 60.0 mL of deionized water, stir to dissolve it completely, add 3.0 g sodium aluminate to the above NaOH solution and stir until completely dissolved, then Dissolve 52.0g of sodium silicate nonahydrate in the above mixture, stir for about 10-20min, and mix well. The above solution was transferred to a three-necked flask, stirred and reacted in a water bath at a constant temperature of 60 °C, and the pH value was adjusted to 14 with nitric acid, and the reaction was maintained for 3 hours. The obtained material was transferred into an autoclave and placed in a dry oven for crystallization at 170 °C for 3 h. The crystallized product was taken out and filtered, then fully washed with deionized water, ...

Embodiment 3

[0056] 1. Support body preparation: select stainless steel metal sheet as the support body, first wash it with ethanol ultrasonically, then wash it with deionized water and then dry it.

[0057] 2. Preparation of cancryptite molecular sieve crystal seeds: Weigh 6.0g NaOH and dissolve it in 60.0mL deionized water, stir to dissolve it completely, add 3.0g sodium aluminate to the above NaOH solution and stir until completely dissolved, then Dissolve 52.0g of sodium silicate nonahydrate in the above mixture, stir for about 10-20min, and mix well. The above solution was transferred to a three-necked flask, stirred and reacted in a water bath at a constant temperature of 60°C, and the pH value was adjusted to 13 with sulfuric acid, and the reaction was maintained for 3 hours. The obtained material was transferred into an autoclave and placed in a dry oven for crystallization at 170 °C for 3 h. The crystallized product was taken out and filtered, then fully washed with deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com