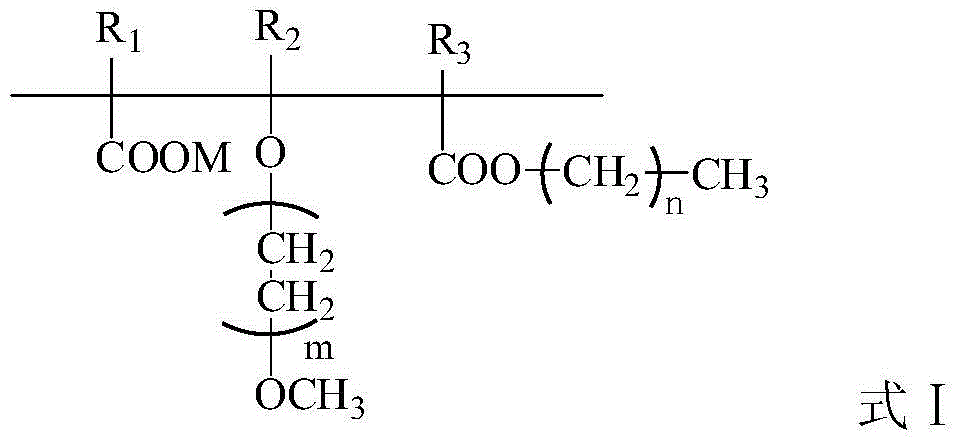

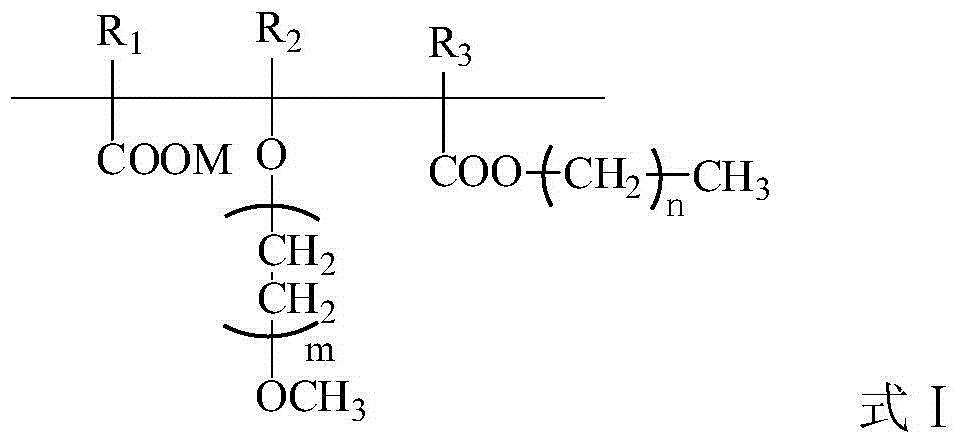

Viscosity-control type polycarboxylate superplasticizer and preparation method thereof

A technology of polycarboxylic acid and water reducer, which is applied in the field of concrete admixtures, can solve problems such as retention and performance affecting stability, and achieve the effects of improved flow performance, stable performance and good working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

[0030] Example 1-13, Preparation of viscosity-adjusting polycarboxylate superplasticizer (VCPC)

[0031] Examples 1-13 The raw material formula and main process parameters of the viscosity-adjusting polycarboxylate water reducer are shown in Table 1:

[0032] Table 1 Example 1-13 Raw material formula and main process parameters of viscosity-adjusting polycarboxylate superplasticizer

[0033]

[0034]

[0035] Embodiment 1-13 Preparation of viscosity-adjusting polycarboxylate water reducer:

[0036] 1) Preparation of viscosity-adjusting monomer C: Prepare a surfactant aqueous solution with a concentration of 0.2-6g / L; according to the dosage of viscosity-adjusting monomer (C) listed in Table 1, dissolve in 30-60mL of surfactant aqueous solution (dosage 2wt% of the mass of the viscosity adjusting monomer). The surfactant can be one or more of sodium dodecyl sulfate, sodium dodecylbenzene sulfonate, spanner type surfactant, tween type surfactant, etc., and it is used here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com