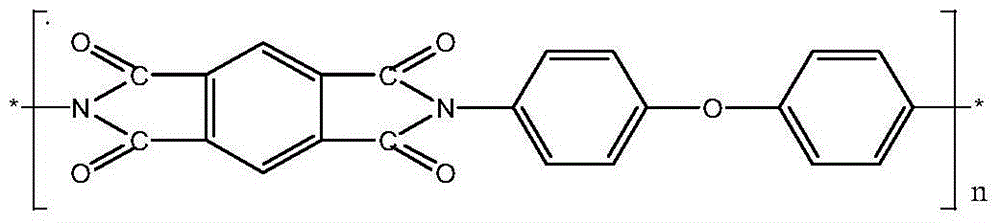

Method of recovering polyimide raw material by hydrolyzing polyimide waste thin film by ammonia water

A polyimide and film technology, which is applied in the field of polyimide raw material recovery from waste polyimide film by ammonia hydrolysis, can solve problems such as poor product quality and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

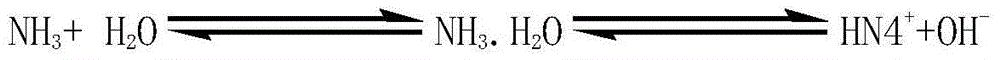

Method used

Image

Examples

Embodiment 1

[0025] 2000g of discarded polyimide film that has been crushed into a length of 7mm is put into 37000ml of ammoniacal liquor with a concentration of 27% by weight, in a stainless steel 316L hydrolysis kettle at a temperature of 200°C and a pressure of 1.4MPa for 3 hours of hydrolysis reaction, cooling, filtering, and Separate the product pyromellitic acid and 4,4'-diaminodiphenyl ether, filter the obtained 4,4'-diaminodiphenyl ether solid, wash with water three times, recrystallize with alcohol, cool to below 40°C, filter , the obtained solid was dried at a temperature of 120°C for 3 hours, then sublimated in a sublimation kettle at a temperature of 190-192°C and a pressure of 0.2-0.3 mmHg, and the purity of the solid product of 4,4'-diaminodiphenyl ether obtained by sublimation was 99.9 %, melting point 192-193°C. The yield is 955g (theoretical yield is 960g).

[0026] The mother liquor obtained by filtration contains pyromellitic acid and unreacted ammonia water, and the hy...

Embodiment 2

[0028] In addition to the input concentration of 3300ml of ammonia water of 30% by weight, pyromellitic acid was dehydrated at a temperature of 260°C for 2 hours, the length of the discarded polyimide film was 10mm, and the sublimation temperature of pyromellitic dianhydride was 260°C. Anhydride yield is except that 1030g, other operation steps and product quality are the same as embodiment 1.

Embodiment 3

[0030] Except that the length of polyimide waste film is 5mm, pyromellitic acid is dehydrated at 250°C for 3 hours, the sublimation temperature of pyromellitic dianhydride is 250°C, and the yield of pyromellitic dianhydride is 1010g, other operations Step and product quality index are the same with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com