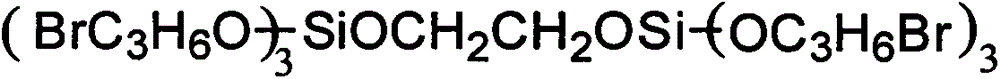

Flame retardant ethylenedioxy dual-silicate propyl bromide and preparation method thereof

A flame retardant and compound technology, which is applied in the field of flame retardant bis[trisilyloxy]ethane compound and its preparation, can solve the problems such as difficulty in finding substitutes, and achieve good symmetry, low volatility, and relative good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

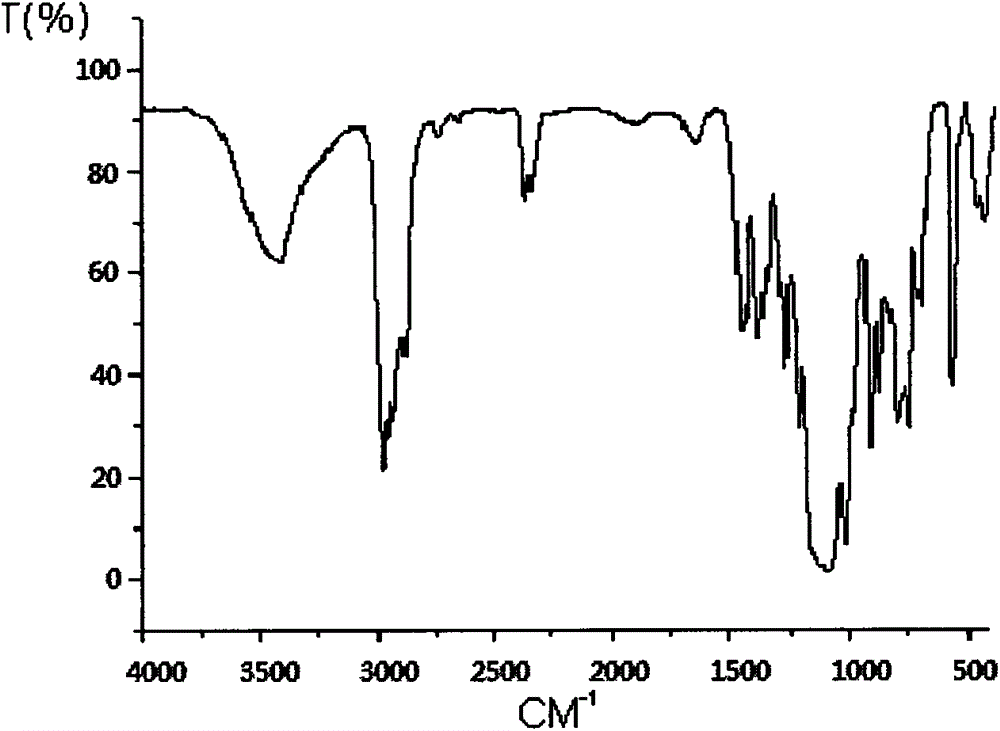

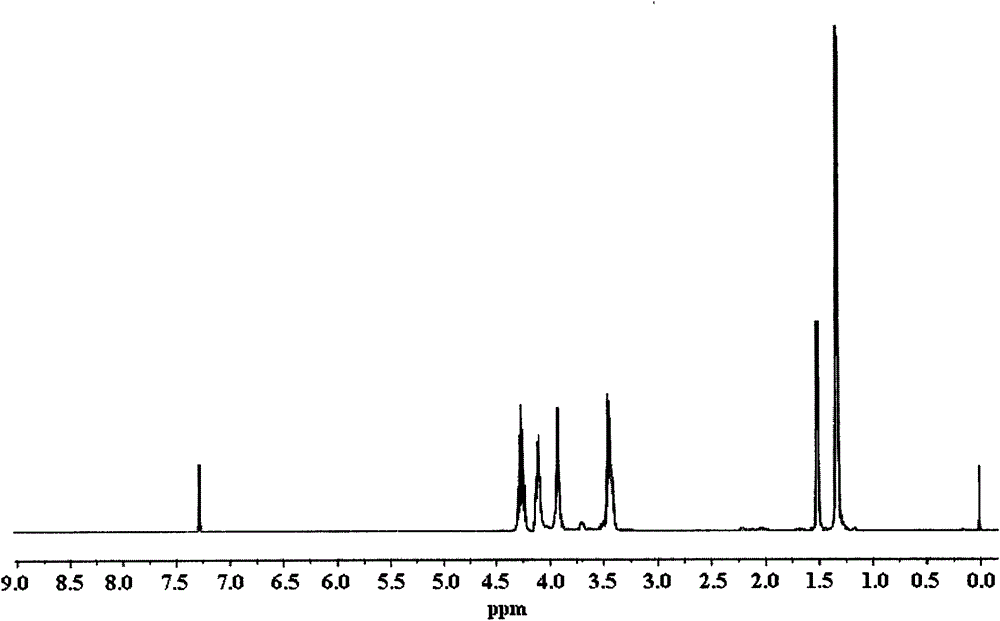

Method used

Image

Examples

Embodiment 1

[0033]Embodiment 1 In the 250ml four-necked flask that stirrer, thermometer and high-efficiency reflux condenser are housed, and drying tube is housed on the condenser upper mouth, replace the air in the bottle with nitrogen, add 60ml carbon tetrachloride and 17g (11.47ml, 0.1mol) silicon tetrachloride, under stirring, cool with cold water bath, make reaction system temperature drop below 25 ℃, dropwise add 13.9g (8.92ml, 0.1mol) bromopropanol, dropwise process control The reaction temperature is not higher than 30°C. After dropping, raise the temperature to 45°C and keep the temperature for 2 hours; The dropping rate controls the reaction temperature not to be higher than 50°C. After the dropping, the temperature is raised to 55°C and reacted for 10 hours; after the HCl gas is released, the temperature of the system is lowered to below 40°C, and 27.939g (17.93ml, 0.201mol) of bromine is added dropwise Propanol, control the reaction temperature not higher than 55°C with the dr...

Embodiment 2

[0034] Example 2 In a 250ml four-necked flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, and a drying tube on the condenser, replace the air in the bottle with nitrogen, add 60ml of acetonitrile and 17g (11.47ml , 0.1mol) silicon tetrachloride, under stirring, cool with a cold water bath, make the reaction system temperature drop below 25 ℃, dropwise add 13.9g (8.92ml, 0.1mol) bromopropanol, dropwise process control reaction temperature not If the temperature is higher than 30°C, after dropping, raise the temperature to 45°C, and keep it warm for 2 hours; after the HCl gas is released, drop 3.1g (2.78ml, 0.05mol) of ethylene glycol into the four-necked flask, controlled by the dropping rate The reaction temperature was not higher than 50°C. After the dropwise addition, the temperature was raised to 60°C and reacted for 9 hours; after the HCl gas was released, the temperature of the system was lowered to below 40°C, and 29.19g (18.73ml, 0.21mo...

Embodiment 3

[0035] Example 3 In a 250ml four-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, and a drying tube on the upper mouth of the condenser, replace the air in the bottle with nitrogen, add 60ml of dioxane and 17g (11.47ml, 0.1mol) silicon tetrachloride, under stirring, cool with cold water bath, make reaction system temperature drop below 25 ℃, dropwise add 13.9g (8.92ml, 0.1mol) bromopropanol, dropwise process control The reaction temperature is not higher than 30°C. After dropping, raise the temperature to 45°C and keep the temperature for 2 hours; The dropping rate controls the reaction temperature not to be higher than 50°C. After the dropping, the temperature is raised to 70°C and reacted for 7 hours; after the HCl gas is released, the system is cooled down to below 40°C, and 30.58g (19.62ml, 0.22mol) of bromine is added dropwise For propanol, the reaction temperature should not be higher than 55°C at the rate of addition. After the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com