A method for preparing jasmine extract by utilizing high-frequency ultrasonic cavitation technology

A jasmine extract and ultrasonic technology, applied in the chemical/physical/physicochemical process of applying energy, fat production, solid solvent extraction, etc., to achieve the effect of improving extraction efficiency and final quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

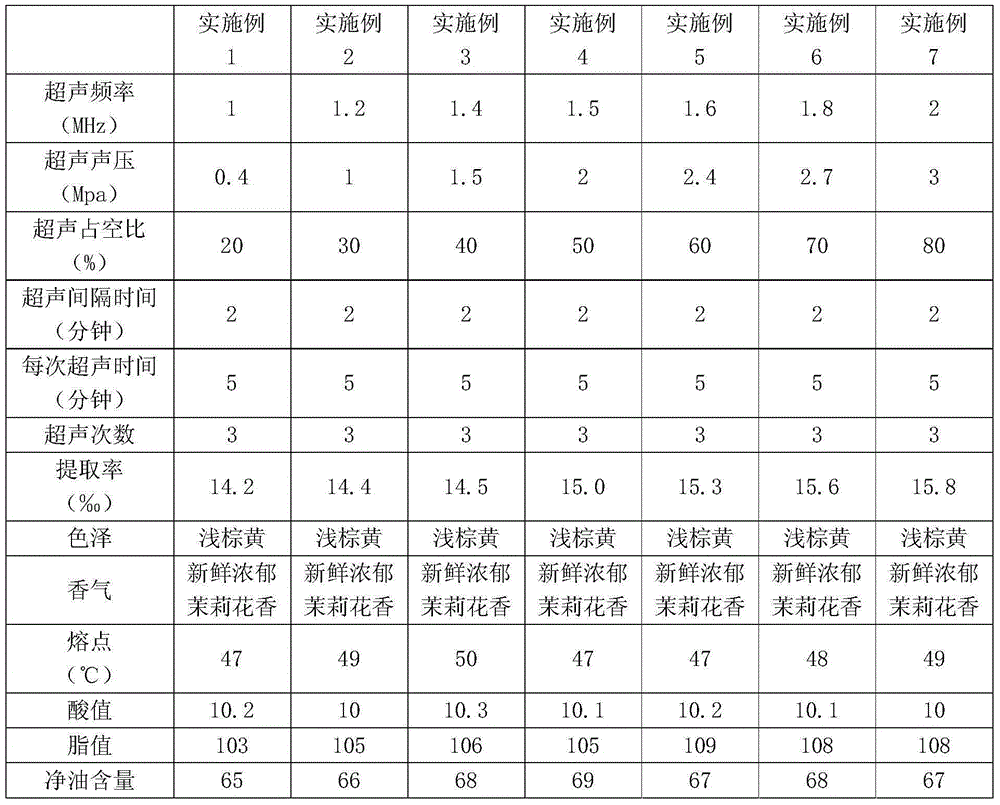

Examples

Embodiment

[0026] A method utilizing high-frequency ultrasonic cavitation technology to prepare jasmine extract, comprising the following steps:

[0027] A. Add the extraction solvent in the ultrasonic extraction tank, put the jasmine flower into the extraction solvent, make the solvent submerge the jasmine flower, and stir evenly;

[0028] B. During the stirring process, the ultrasonic generator is turned on intermittently, and the megahertz band ultrasonic wave is directly applied to the mixed liquid;

[0029] C. filtering the supernatant of the extract, and squeezing the raffinate, merging the filtrate and the squeezing liquid;

[0030] D. Extract the combined filtrate and squeezed liquid to obtain jasmine extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com