Preparation method for ultrahigh-concentration wort

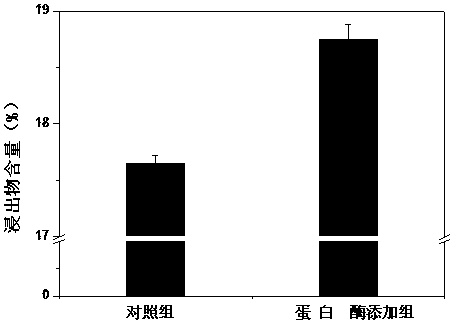

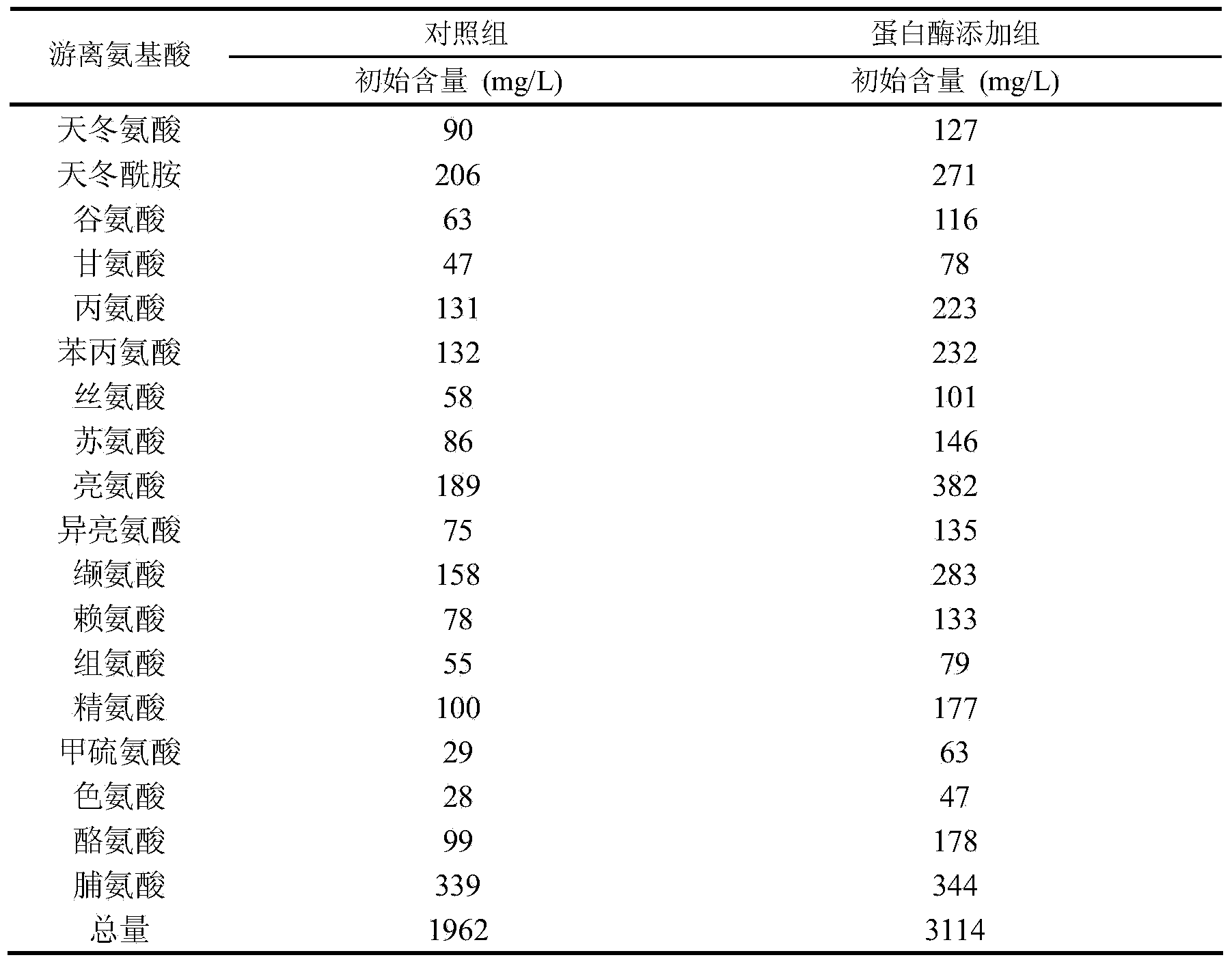

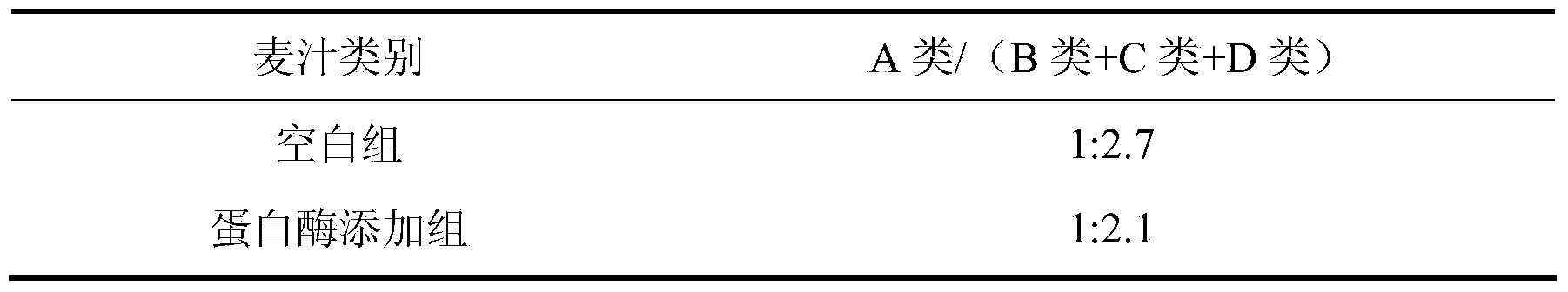

A wort, ultra-high technology, applied in the field of preparation of ultra-high-concentration wort, can solve the problems of nitrogen source shortage and unreasonable nitrogen source composition, and achieve the effects of reasonable composition, quality improvement, and high fermentation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) Take an appropriate amount of malt, coarsely crush it, adjust the pH of the feeding water to 5.2 with lactic acid, and then feed and mix it with a material-to-water ratio of 1:5 to obtain a mash. Add a compound protease (provided by Novozymes) and neutralizing The mixture of protease (provided by Novozymes) was incubated at 40°C for 25min, the total amount of the compound protease and neutral protease added was 0.5g / L mash, and the mass ratio of compound protease and neutral protease was 1:1 Then heat up to 50°C and add flavor protease (provided by Novozymes), the amount of flavor protease added is 0.3g / L mash, and saccharify for 25min; heat up to 60°C, add compound protease again, the amount added is 0.2g / L mash The temperature was raised to 70°C and saccharified for 8 minutes; finally the temperature was raised to 76°C and the enzyme was inactivated for 10 minutes; the speed of the temperature increase was 1°C / min; / w) Boil in a boiling pot for 80 minutes, gyrate ...

Embodiment 2

[0018] (1) Take an appropriate amount of malt, coarsely crush it, adjust the pH of the feeding water to 5.2 with lactic acid, and then feed and mix it with a material-to-water ratio of 1:6 to obtain a mash. Add a compound protease (provided by Novozymes) and neutralizing The mixture of protease (provided by Novozymes) was incubated at 45°C for 30min, the total amount of the compound protease and neutral protease added was 0.8g / L mash, and the mass ratio of compound protease and neutral protease was 2:1 Then heat up to 55°C and add flavor protease (provided by Novozymes), the amount of flavor protease added is 0.6g / L mash, and saccharify for 30min; heat up to 63°C, add compound protease again, the amount added is 0.4g / L mash solution, maintained for 30min; heated to 72°C, saccharified for 10min; finally raised to 78°C, enzyme inactivated for 10min; the speed of the heating was 1°C / min; and then filtered to obtain clarified wort, adding granular hops 0.1% (w / w) Boil in a boilin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com