Centrifuge tube with cell filter

A cell filter and centrifuge tube technology, applied in the field of centrifuge tubes, can solve problems such as unfavorable energy saving and environmental protection, energy transition loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

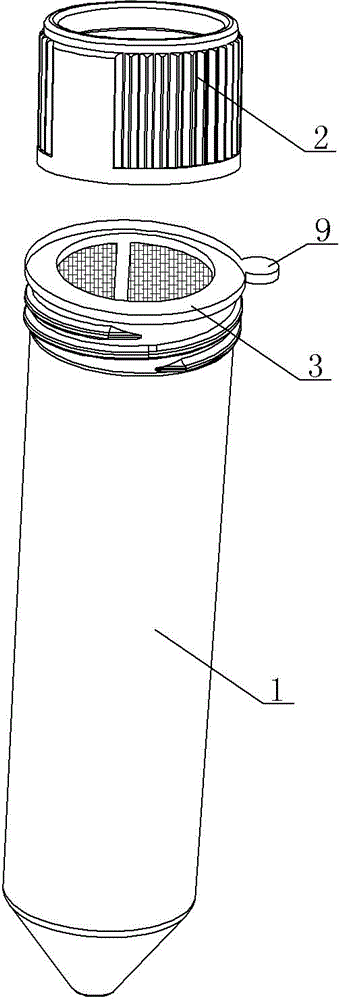

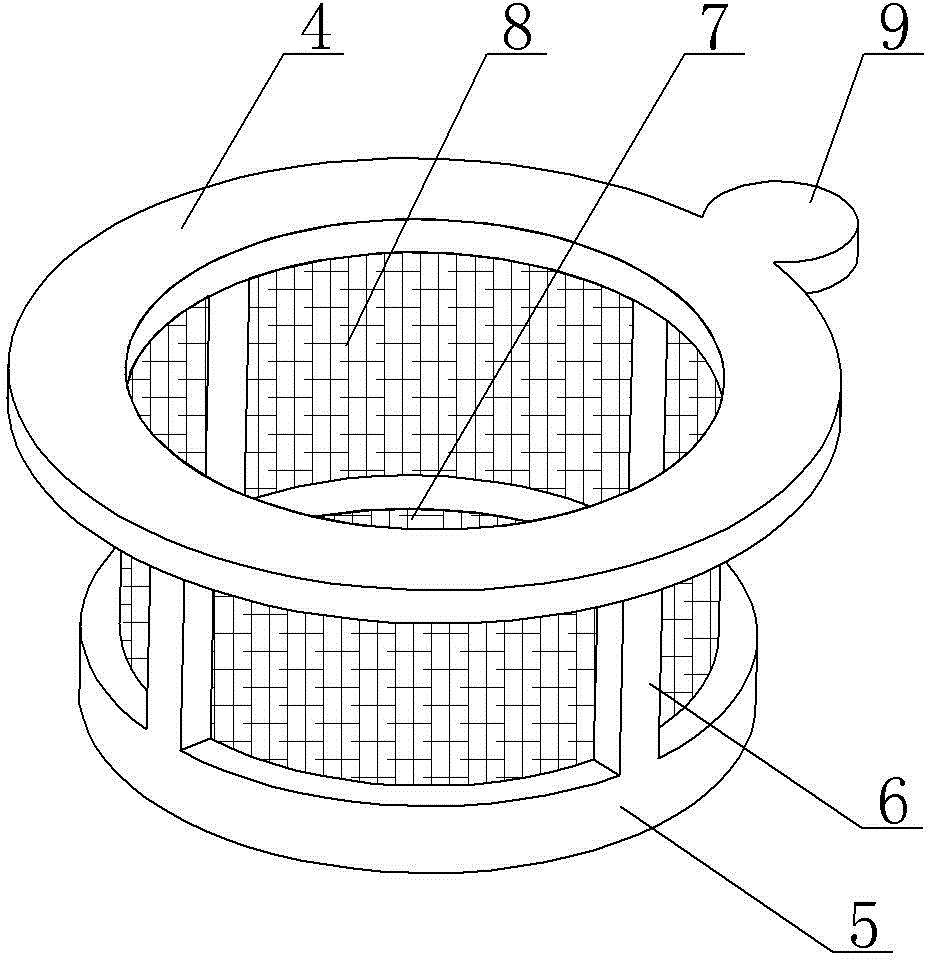

[0010] See figure 1 , figure 2 , which includes a tube body 1 and a cover 2. The cover 2 in a centrifugal state is connected to the upper end of the tube body 1 by threads, and it also includes a cell filter 3. The cell filter 3 specifically includes a frame and a filter membrane, and the frame includes an upper annular surface 4. The lower annular surface 5, the middle connecting rod 6, the upper annular surface 4, and the lower annular surface 5 are connected by the intermediate connecting rod 6. The filter membrane includes a bottom filter membrane 7 and an outer annular filter membrane 8. The lower end surface of the outer circle part of the bottom filter membrane 7 is supported on the inner upper end surface of the lower annular surface 5, the upper end surface of the outer circle part of the bottom filter membrane 7 is connected to the outer annular filter membrane 8, and the outer annular filter membrane 8 is close to the middle connecting rod 6 surrounded by the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com