Hydraulic system for stratum sampling instrument

A technology of hydraulic system and sampler, which is applied to fluid pressure actuating system components, fluid pressure actuating devices, servo motors, etc., can solve the problems of high use cost, complex system, low reliability, etc., and achieve reliable working performance, Good high temperature performance and the effect of simplifying the hydraulic circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

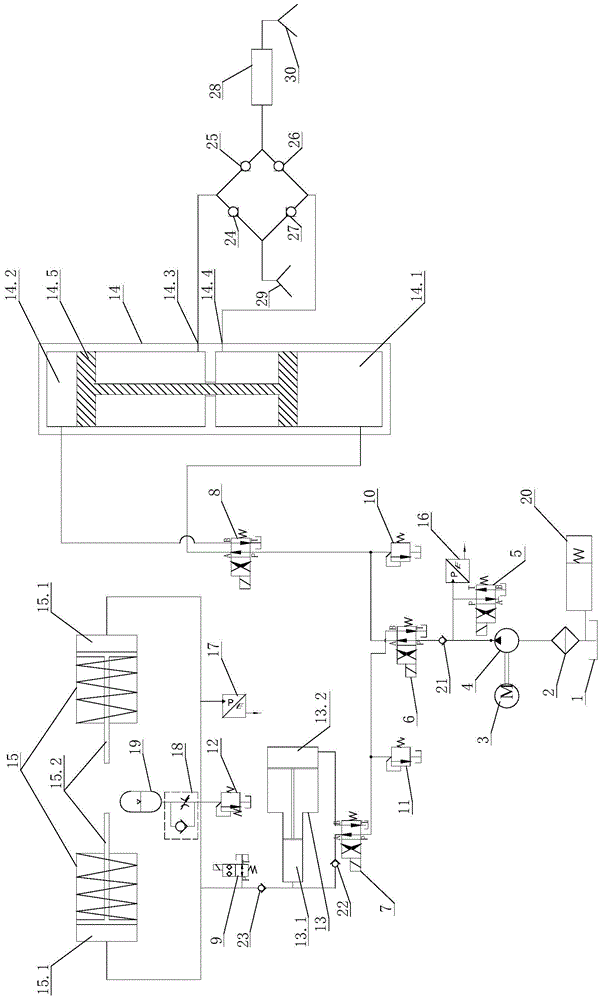

[0027] Such as figure 1 As shown, the hydraulic system used for the stratum sampling instrument includes a fuel tank 1, a filter screen 2, a high-speed plunger pump 4, a high-speed motor 3 for driving the high-speed plunger pump 4, a balance oil bag 20, a booster cylinder 13, a pump Oil suction cylinder 14, two sealing oil cylinders 15, four electromagnetic reversing valves, seven check valves,

[0028] The oil suction port of the high-speed plunger pump 4 is respectively connected with the hydraulic oil cavity of the balance oil bag 20 and the oil outlet of the closed oil tank 1 through the filter screen 2;

[0029] The oil outlet of the high-speed plunger pump 4 is divided into two paths, one path is connected to the P port of the first electromagnetic reversing valve 5, and the other path is connected to the inlet of the first che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com