Multifunctional protection ball valve for washing machine

A multi-functional, washing machine technology, applied in the direction of functional valve type, other washing machines, valve energy absorption devices, etc., can solve the problems of water hammer damage, shortened service life, water leakage and flushing, etc., to eliminate backflow pollution and reduce Harmful, highly reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

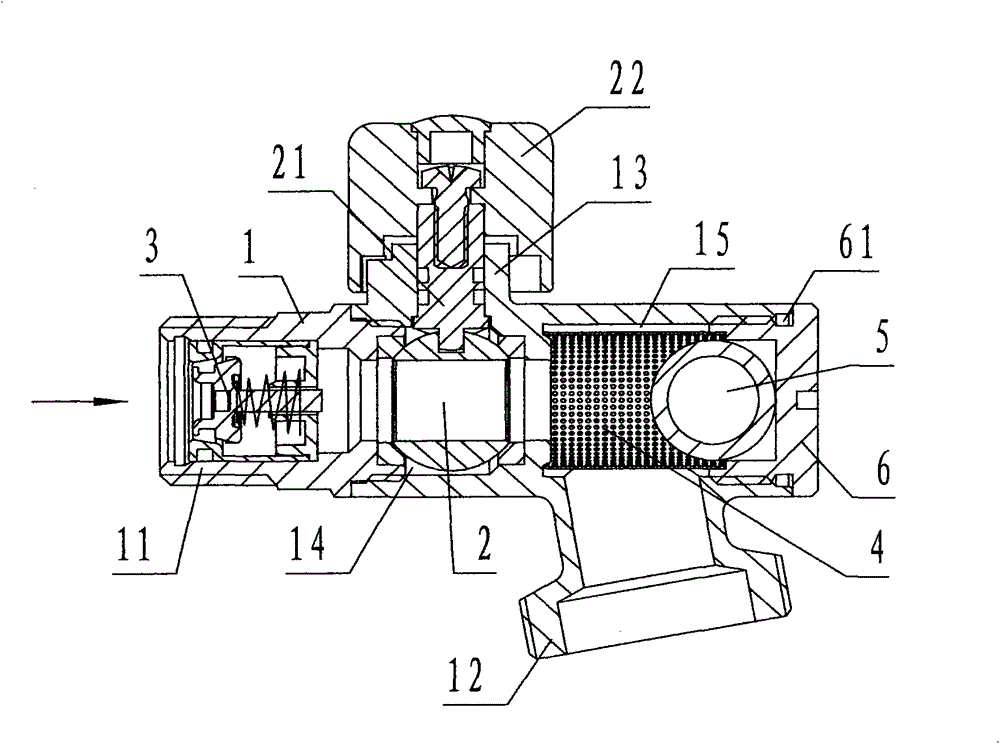

[0025] refer to figure 1 , a multifunctional protective ball valve for washing machines of the present invention, comprising a valve body 1, a ball valve core 2, a ball valve core 2, a valve stem 21, a knob 22, a check core 3, a filter screen 4, a pressure relief ball 5, a plug Cover 6, wherein: the valve body 1 is a hollow four-way tubular copper shell, from left to right, the valve body 1 is provided with a water inlet 11, a valve core chamber 14, a mesh chamber 15, and the valve core A stem seat 13 is provided above the chamber, and a water outlet 12 is provided below the mesh chamber 15, and the outer walls of the water inlet 11 and the water outlet 12 are provided with external threads for connection; the right inner wall of the mesh chamber 15 is provided with There are internal threads connected to the blocking cover 6;

[0026] The non-return core 3 is a spool composed of a piston and a spring, which is unidirectionally conducted from left to right;

[0027] The filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com