Coupling-bionics-based food crispness tester and testing method

A tester and brittleness technology, applied in the direction of testing food, testing material hardness, material inspection products, etc., can solve the problem of no accurate food brittleness testing method, no bionic testing method for judging food brittleness, etc., to overcome subjectivity and simplify structure, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

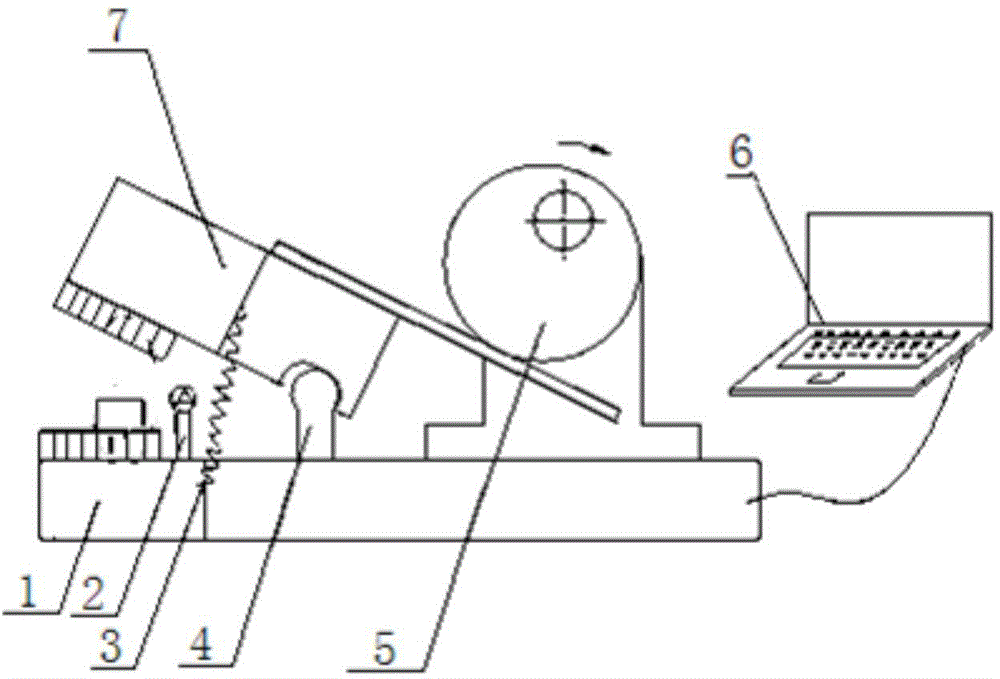

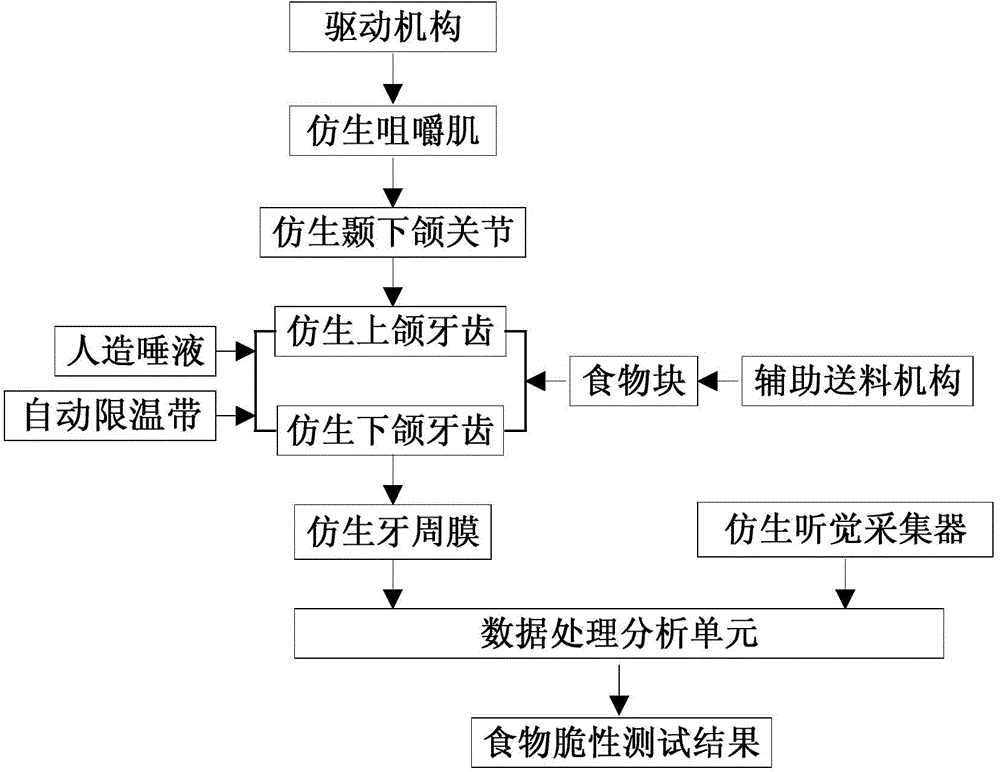

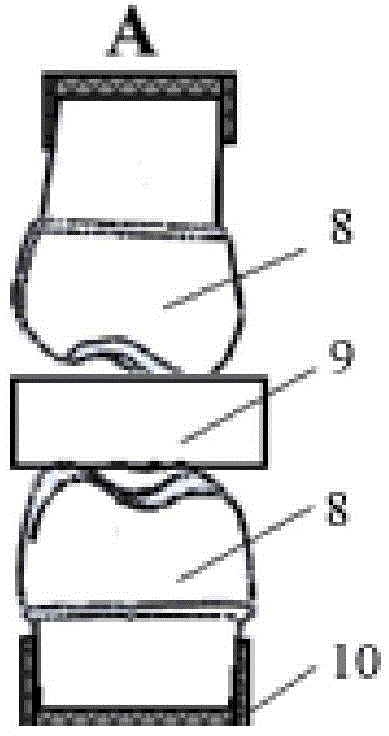

[0083] figure 1 It is a schematic diagram of the structure principle of the bionic brittleness tester, figure 2 For the food brittleness test process diagram, image 3 for bionic teeth, Figure 4 For the bionic jaw, Figure 5 For the bionic temporomandibular joint, Image 6 For the chewing drive mechanism, Figure 7 For the feeding drive mechanism, Figure 8 To imitate the warm and humid environment of the oral cavity, Figure 9 For bionic periodontal ligament, Figure 10 It is a bionic periodontal ligament conversion amplifier circuit, as shown in the figure: a food brittleness tester based on coupling bionics provided by the present invention, including a chewing simulator, a brittle crack signal acquisition system and a data processing and analysis system;

[0084] The chewing simulator is used for simulating the human chewing system to chew broken food;

[0085] The brittle signal acquisition system includes a mechanical brittle signal acquisition unit and a sound...

Embodiment 2

[0140] This embodiment describes in detail the food brittleness tester and testing method based on coupling bionics in conjunction with the accompanying drawings:

[0141] figure 1 It is a schematic diagram of the structure principle of the bionic brittleness tester, figure 2 It is a food brittleness test process, as shown in the figure, the brittleness test process of the present invention is mainly to simulate the process of human eating, chewing, and perception. Firstly, the auxiliary mechanism sends the food block into the bionic mandible, and then the driving mechanism sends the food block into the tooth and maxillofacial surface of the bionic mandible, and at the same time pulls the bionic masticatory muscles to drive the bionic upper jaw to realize chewing and crushing movement in the bionic temporomandibular joint; during this process The medium temperature and humidity environment component inputs artificial saliva to the bionic teeth and food block, and maintains a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com