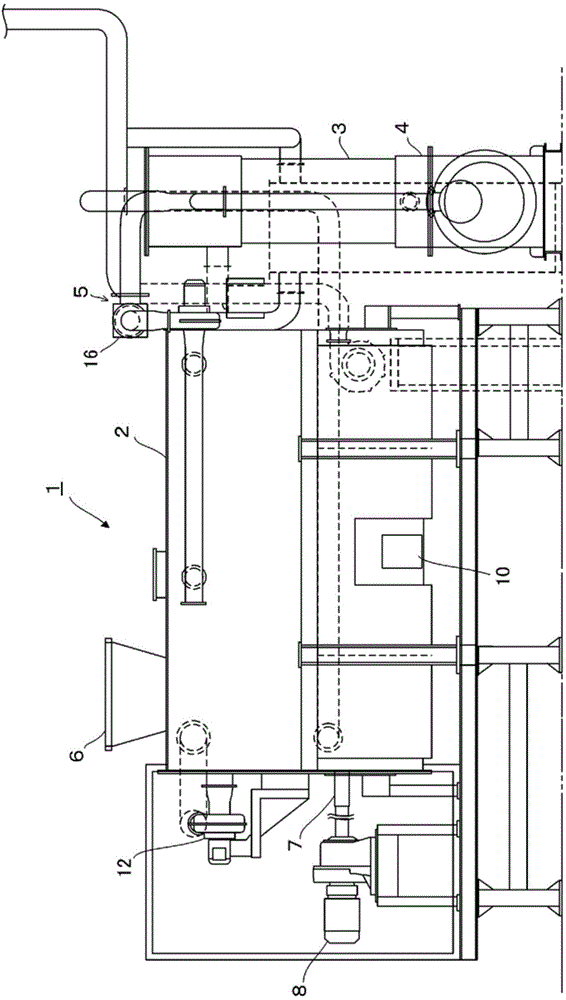

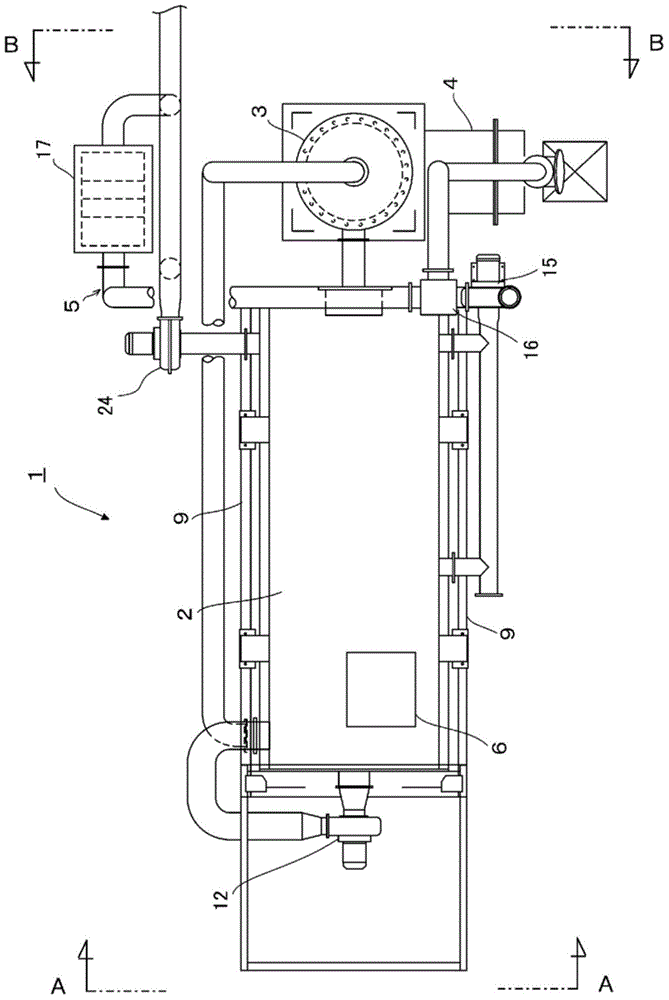

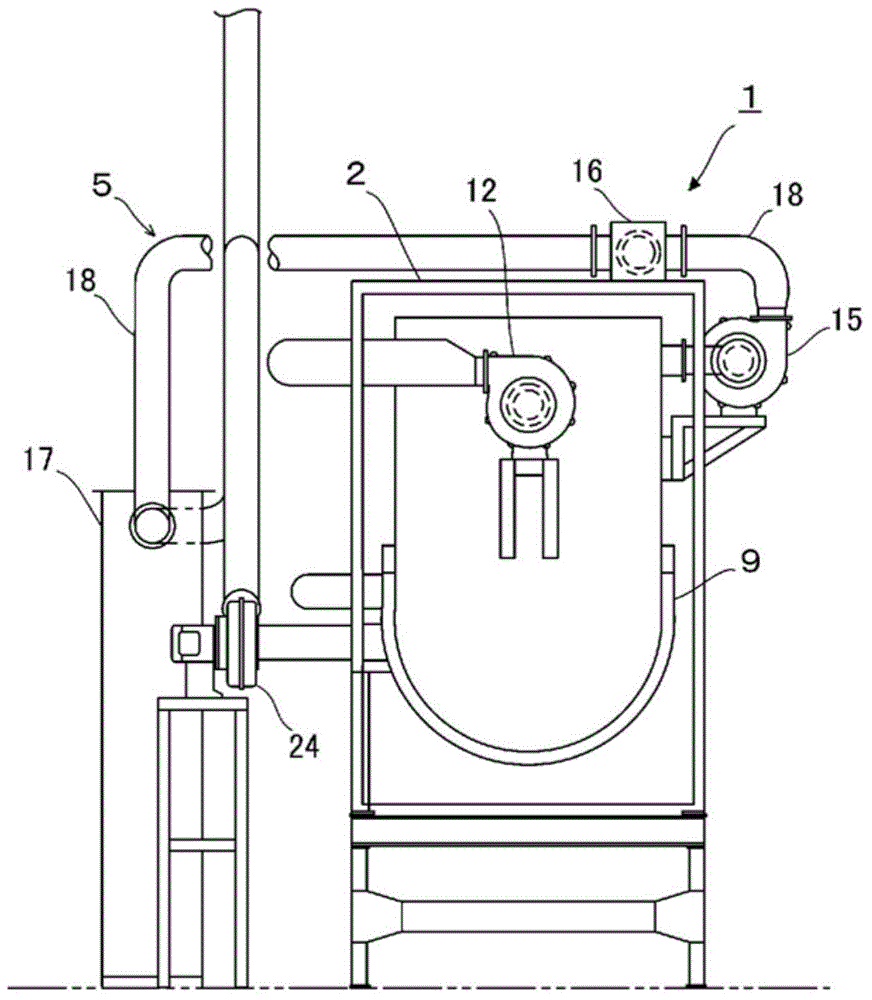

Organic waste treatment device

A treatment device and waste technology, applied in biological sludge treatment, animal husbandry wastewater treatment, food industry wastewater treatment, etc., can solve problems such as dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Next, an example of organic waste treatment by the organic waste treatment apparatus of the present invention will be described.

[0043] (organic waste)

[0044] Animal residue 1000Kg

[0045] Wild vegetable residue 1000Kg

[0046] (moisture adjustment material)

[0048] (bacteria for fermentation)

[0049] Inner city bacteria (inner city bacteria) 265Kg

[0050] (processing conditions)

[0051] Heating time 10-13 hours

[0052] Cooling time 2 to 2.5 hours

[0053] (result)

[0054] The resulting product is a coarse powder with a water content of 15% or less, without the generation of bad odor, and can be used as a raw material for fertilizer and feed.

[0055] As described above, according to the organic waste treatment device of the present invention, the combustion gas of the main burner is used as external heating of the treatment tank, and the outside air heated by the heat exchanger circulates in the treatment tank and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com