Process for producing foamed wallpapers

A technology of foam coating and base material, applied in the field of preparation of foam wallpaper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

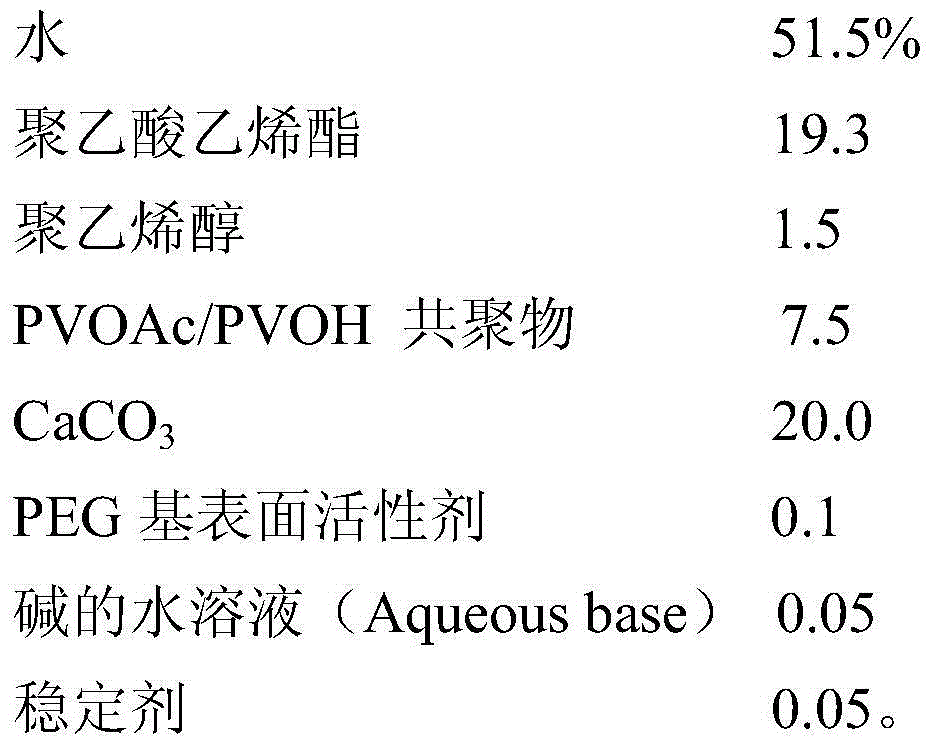

[0054] Prepare a mixture of:

[0055]

[0056] The pigment is ground and homogenized in the dispersed phase. Adjust the pH to about 7.

[0057] The viscosity is about 3500mPas, 25°C (EN ISO2555, Brookfield viscometer).

[0058] Density is about 1.45g / cm 3 .

[0059] The resulting mixture was processed in a foam generator using air as gas to obtain a foam; ratio of coating agent to air=55:45.

[0060] A 2 mm thick layer was obtained from the foam on a sheet of paper (10x10 cm) using a doctor blade.

[0061] The resulting layer was dried in a circulating air oven at 130° C. for 30 seconds.

[0062] A paper substrate was obtained with a dry layer; the layer thickness was about 1.8 mm. The surface is non-stick and soft, and can be embossed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com