Preparation method of corn stigma tea

A manufacturing method, corn silk technology, applied in the field of corn silk tea manufacturing, can solve the problems of no involvement, expensive removal, lower tea preference, etc., and achieve the effect of increasing taste and aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

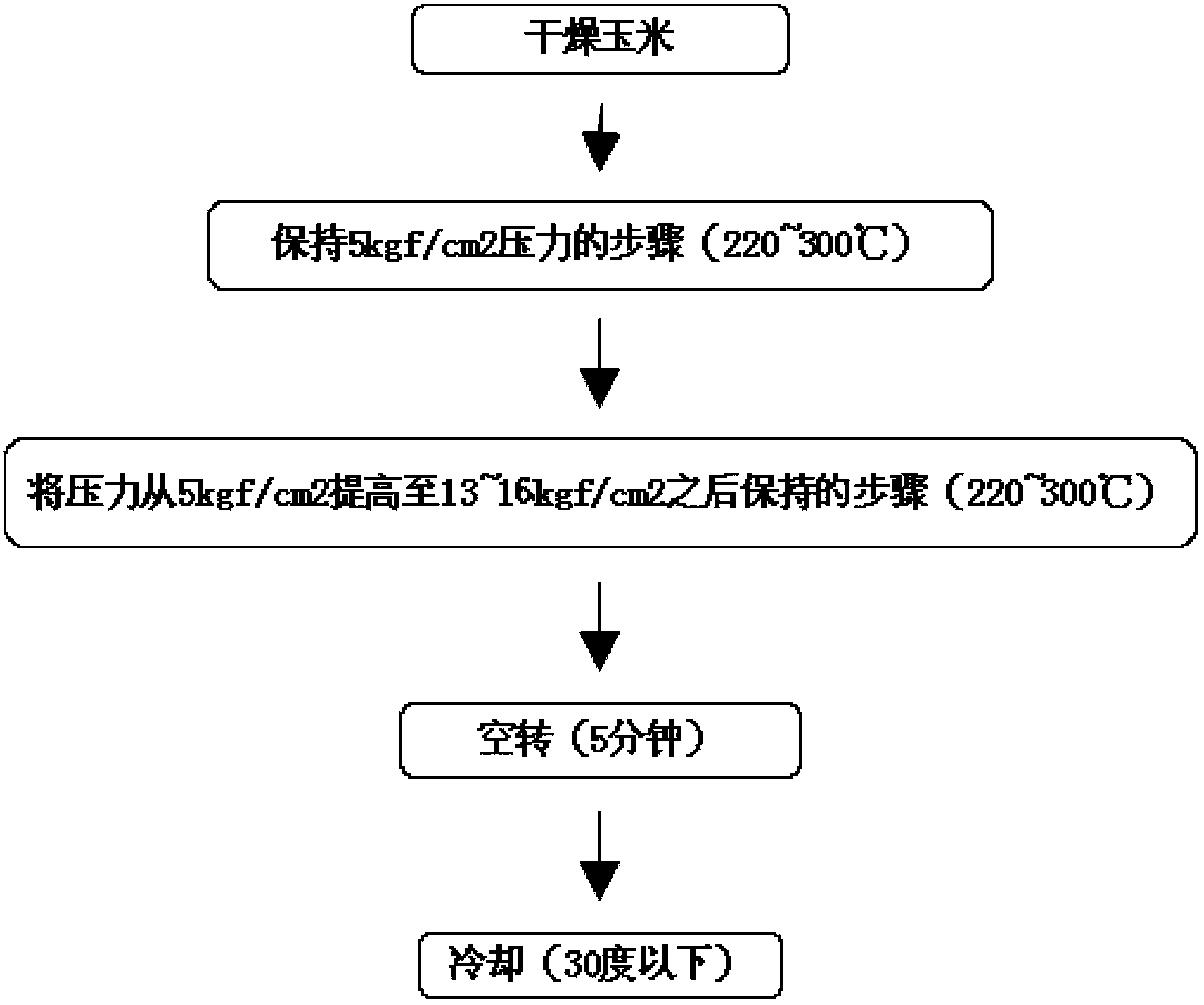

[0050] Example 1 The manufacture of corn silk tea according to the present invention

[0051] first step: Manufacture of Corn Silk Concentrate

[0052] After washing 300 kg of corn silk raw material with flowing water for about 3-5 minutes, it was sterilized at 135° C. for 1 hour. After washing the sterilized corn silk material for the second time with running water for about 3-5 minutes, add about 25 times the amount of purified water for extraction at 98-100°C, and cool the extract to After 40°C, filter with 300 mesh. 85-90 kg of diatomaceous earth (1.0-1.5 volume % diatomite relative to the total filtrate) was put into the filtrate, stirred, and filtered through diatomaceous earth for about 1 hour. Because there may be tiny particles passing through the filter cloth in the filtrate, after filtering the filtrate with a microfilter, the filtrate is concentrated under reduced pressure to obtain 40Brix° at a temperature below 60°C The above solid components are sterilized...

Embodiment 2 to 6

[0063] Examples 2 to 6 Manufacture of corn silk tea according to the present invention

[0064] The first step, the third step to the sixth step are manufactured by the same method as in the above-mentioned embodiment 1. In the second step, fried corn was produced by the same method as in the second step of Example 1 with the baking conditions in the following Table 1 and used as Examples 2 to 6.

[0065] Table 1

[0066] differentiate

experiment example 1

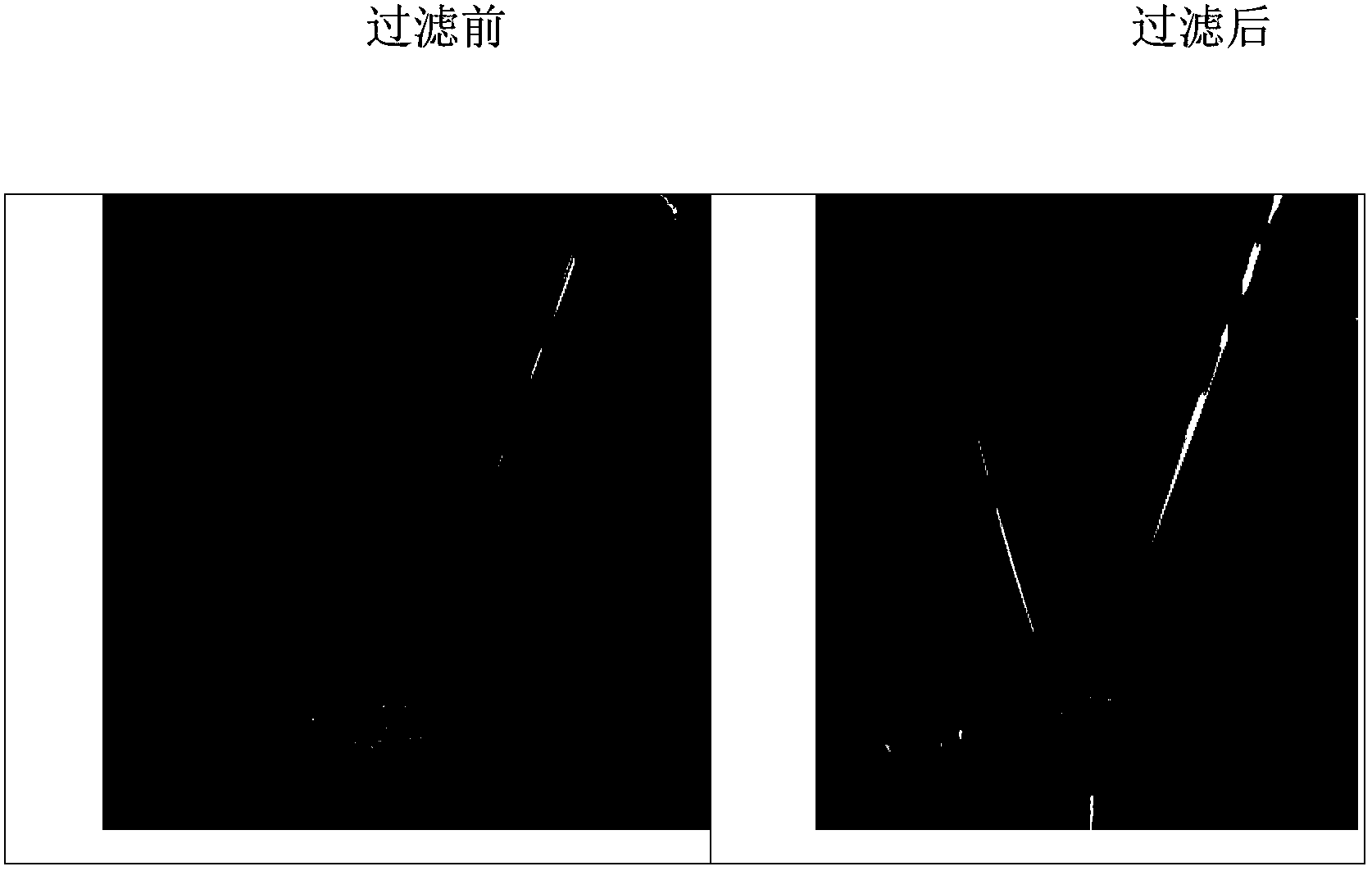

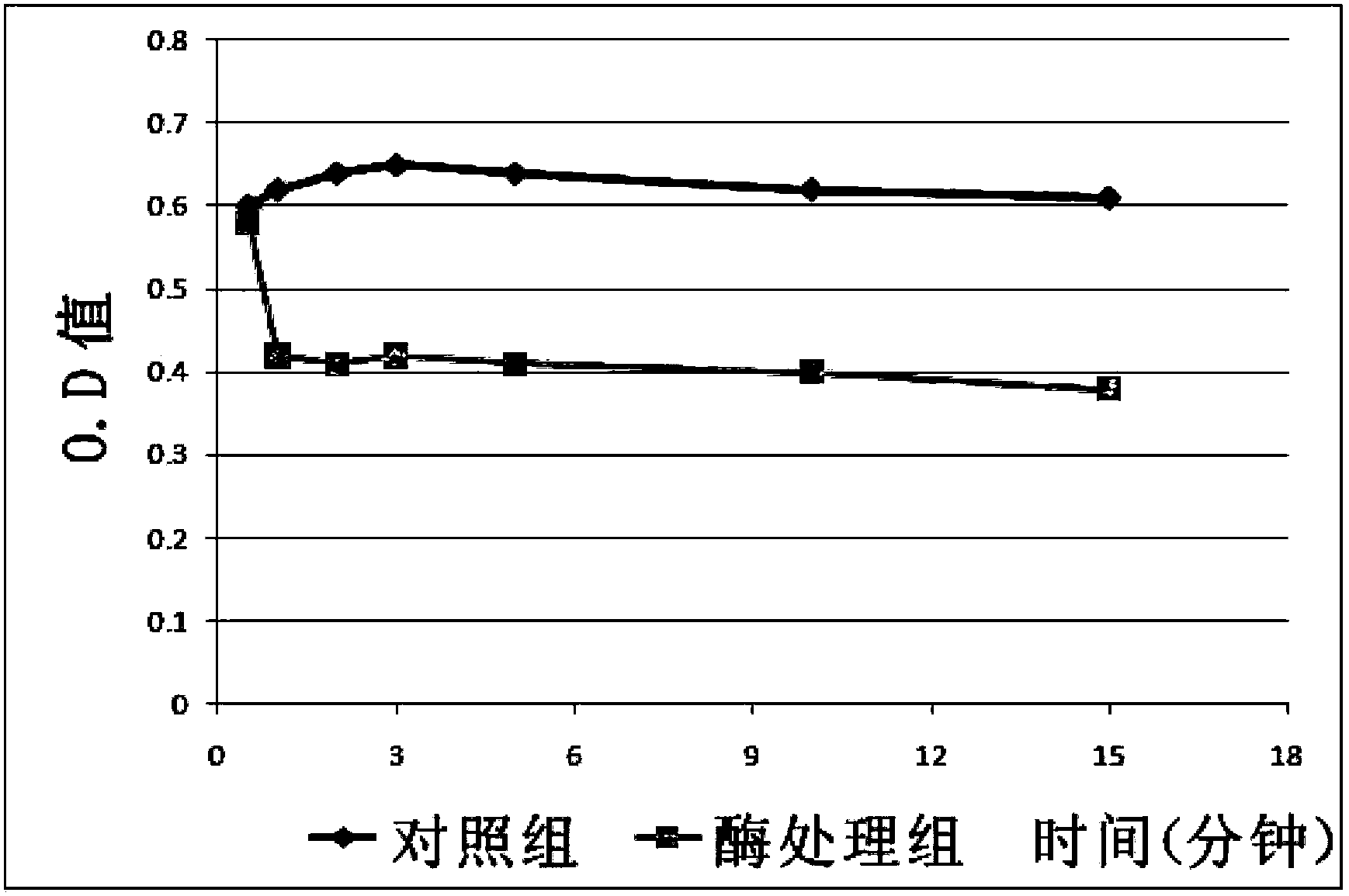

[0071] Experimental example 1 Confirm the removal effect of sediment and impurities in corn silk concentrate

[0072] Through the filtrate before and after filtration with diatomaceous earth, the effect of removing sediment and impurities in the corn silk extract produced by the present invention was confirmed. After uniformly mixing a certain amount of diatomite and corn silk extract, use a filter press filter device and filter cloth to filter and compare the sediment before and after filtration. The results of the sensory and filtration comparison experiments based on different amounts of diatomite are shown in the following table 3.

[0073] *Sensory evaluation: 20 adult males and females, using the standard 5-point method (comprehensively evaluate the aroma and taste and score. 5 points: very good; 4 points: good; 3 points: general; 2 points: not good; 1 point: very not good)

[0074] *Precipitation experiment: compare the precipitation rate produced by using the corn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com