Manufacturing method of additive for complete feed

A technology of full-price feed and manufacturing method, applied in animal feed, animal feed, application, etc., can solve the problems of affecting health, large amount of medicine, and large drug residue, so as to enhance the immunity of poultry and livestock without residue of harmful ingredients , The effect of simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] A method for manufacturing additives for complete feed, comprising the following steps:

[0048] A, select bamboo leaf, sealwort, gallinacea powder to dry respectively, pulverize into 100 mesh size with pulverizer, obtain bamboo leaf powder, sealwort and gallinacea powder after sieving; set aside;

[0049] B. Stir the yeast or spores with the grain buds together, stir for 40 minutes, wrap them in plastic cloth, ferment at 45 degrees Celsius for 3 days, and set aside;

[0050] C, the protein powder, plant enzymes. After the lipase and yam powder are mixed, the mixture obtained in step B is stirred evenly and then granulated,

[0051] D. During the granulation process of step C, the mixture obtained in step B is used as a coating to wrap the outer surface of the granules to obtain additives for full-price feed, packed in small bags, 1 kg per bag, and stored at 18 degrees Celsius.

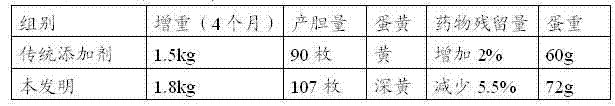

[0052] The additives for full-price feed prepared by the manufacturing method of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com