Inertial separation and dust removing device on catering stove

An inertial separation and dust removal device technology, applied in the field of inertial separation dust removal device and dust removal device, can solve the problems of complex structure, increased manufacturing cost, easy corrosion, etc., and achieve the effect of good dust removal effect, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

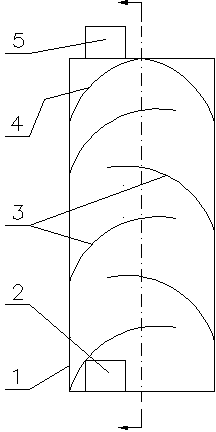

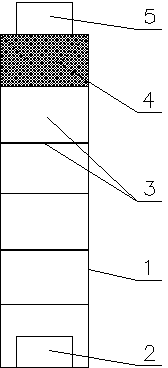

[0010] as attached figure 1 As shown, the casing 1 is a box-shaped structure, the smoke inlet pipe 2 is placed in the lower part of the casing 1, and the smoke outlet pipe 5 is placed in the upper part of the casing 1; the opposite inner walls of the casing 1 are provided with a plurality of relatively staggered partitions 3; The plate 3 is provided with a circular arc, and the concave surface of the circular arc faces the smoke inlet pipe 2; the filter screen 4 is closed in the lower passage of the smoke outlet pipe. The smoke inlet pipe 5 in the device is connected to the smoke outlet of the stove, and the dust-laden flue gas discharged from the stove enters through the smoke inlet pipe 2, and passes through a plurality of partitions 3 with arcs, and the smoke is discharged. The flow direction of the gas changes sharply, and the ash particles in it will be blocked and changed by the movement trajectory of the partition plate 3, and an inertial force will be generated to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com