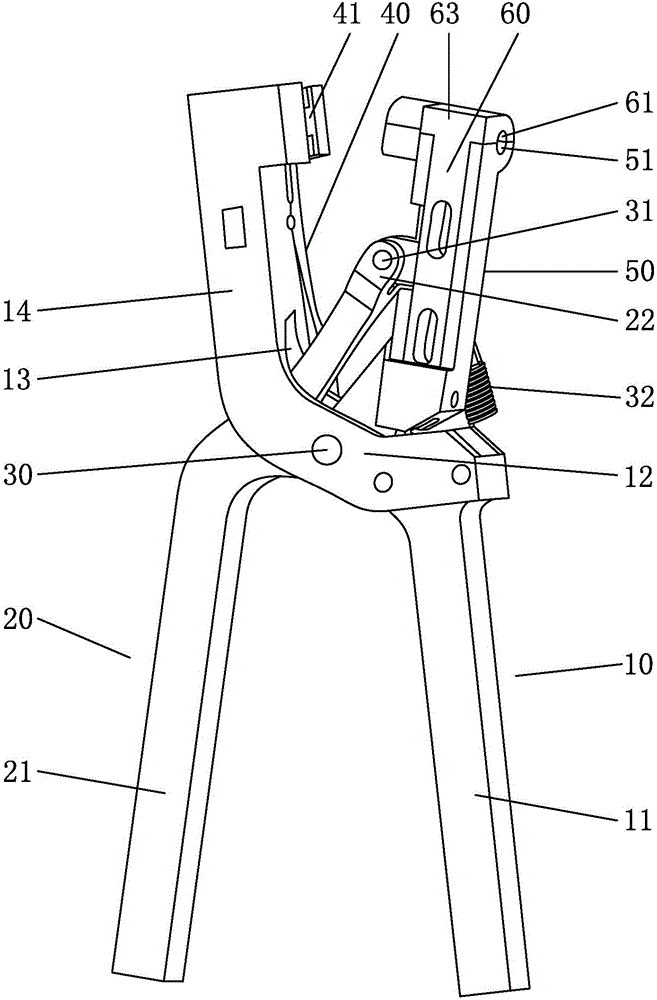

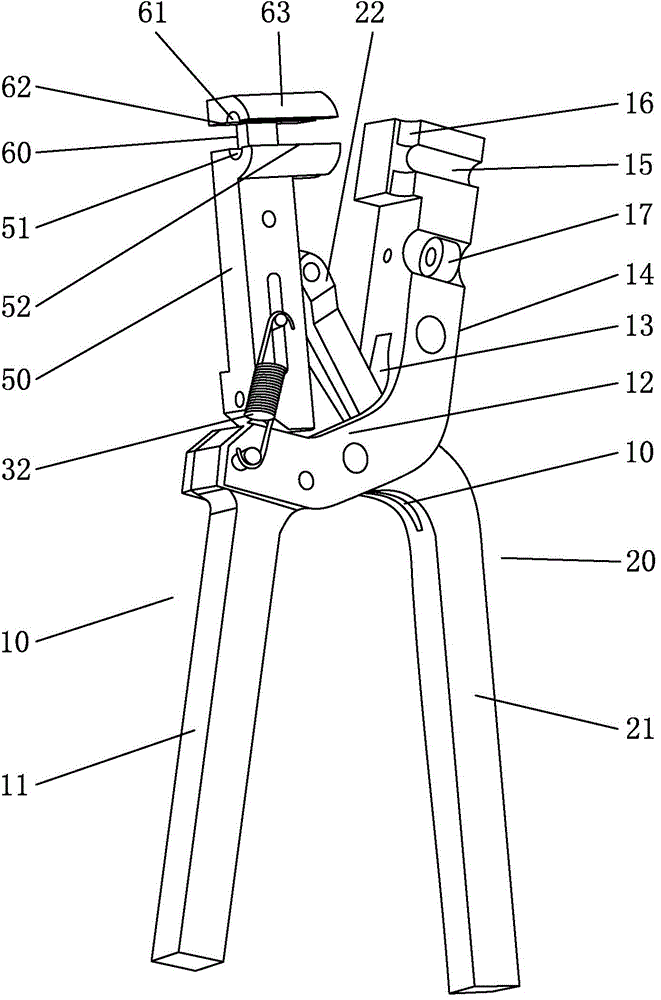

Pipe assembly pliers for right-angle multi-way joints

A multi-way joint and right-angle technology, which is applied in the field of assembly tools for hoses and joints, can solve problems such as skin inflammation and pain on the hands, damage to the hose head, long installation time, etc., to protect the health and safety of the body, High productivity and short installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — figure 2 :

[0019] Connecting pipe assembly pliers for right-angle multi-way joints, the left side of the transverse part 12 of the right pliers arm 10 extends upwards to form the left clamping part 14, and the right side extends downwards to form the right handle 11, and the left side of the transverse part 12 passes through the left pliers arm 20 The hinged shaft 30 is hinged into a cross structure, and the transverse portion 12 on the right side of the hinged shaft 30 is hinged with a right clamping part 50, and the upper end 22 of the left pincer arm 20 is hinged with the middle part of the right clamping part 50 through the hinged shaft 31. The left clamping part 14 is provided with a right-angle multi-way joint clamping device, and the right clamping part 50 is provided with a hose clamping device, and the installation directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com