Drier coating film

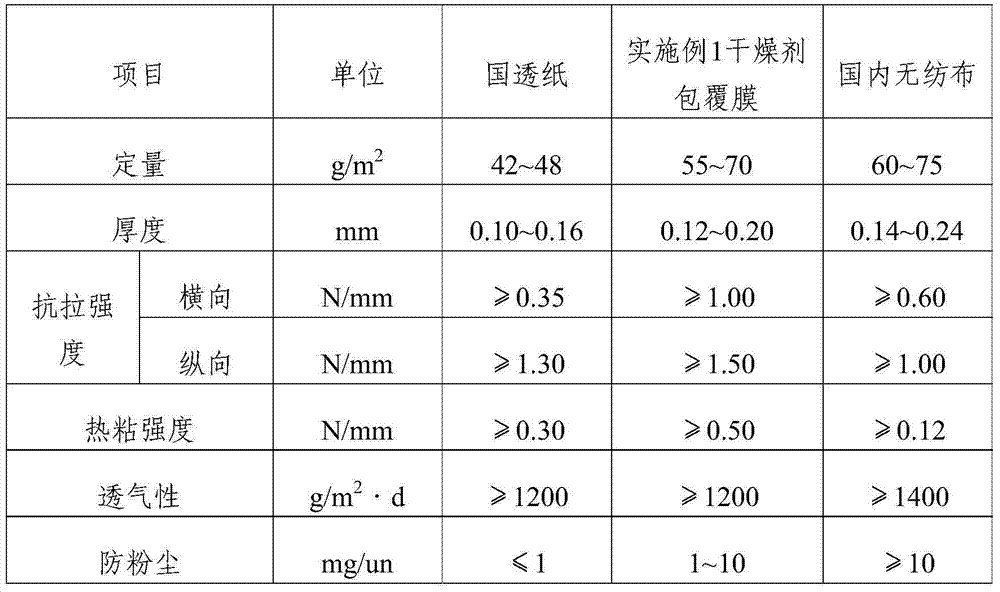

A technology of desiccant and coating film, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., which can solve the problems of non-adaptability, poor strength of national permeable paper or non-woven fabrics, and dust resistance of non-woven fabrics To solve problems such as poor ability, achieve the effect of high dust resistance performance, consistent appearance and surface performance, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Preparation of desiccant coating film of the present invention

[0039] The first step: choose 30g / m 2 PP spunbond nonwoven fabric, 30g / m 2 PP / PE staple fiber spunbond nonwoven fabric

[0040] Step 2: On the non-woven hot-press laminating machine, select a temperature of 140°C, and directly hot-roll and compound it to make 60g / m 2 wit paper.

Embodiment 2

[0041] Example 2 Preparation of desiccant coating film of the present invention

[0042] The first step: choose 20g / m 2 PP spunbond nonwoven fabric, 30g / m 2 PP / PE staple fiber spunbond nonwoven fabric

[0043] Step 2: On the non-woven hot-press laminating machine, select a temperature of 130°C, and directly hot-roll and laminate to make 50g / m 2 wit paper.

Embodiment 3

[0044] Example 3 Preparation of desiccant coating film of the present invention

[0045] The first step: choose 30g / m 2 PP spunbond nonwoven fabric, 20g / m 2 PP / PE staple fiber spunbond nonwoven fabric

[0046] Step 2: On the non-woven hot-press laminating machine, select a temperature of 120°C, and directly hot-roll and compound it to make 50g / m 2 wit paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com