Modified attapulgite clay composite artificial stone material and production method thereof

A technology of attapulgite clay and artificial stone, which is applied in the field of modified attapulgite clay composite artificial stone and its production, which can solve the problems of high polymerization conditions, polymerization reaction time, increased production costs, and large performance differences, and achieve shortening The effect of production cycle, improvement of production efficiency and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The steps of attapulgite clay modification are:

[0052]Step 1, add 3% (v / v) γ-aminopropyltriethoxysilane (KH550) to the high-viscosity attapulgite clay, and use hydrochloric acid to adjust its pH value to 3-4 for later use;

[0053] Step 2, at room temperature, disperse the above slurry for 30 minutes with a disperser at a speed of 2000r / min;

[0054] Step 3, adjusting the temperature to 60°C, and stirring at a low speed of 50r / min for 8h;

[0055] In step 4, the above slurry is separated, dried, crushed and passed through a 200-mesh sieve to obtain modified attapulgite clay.

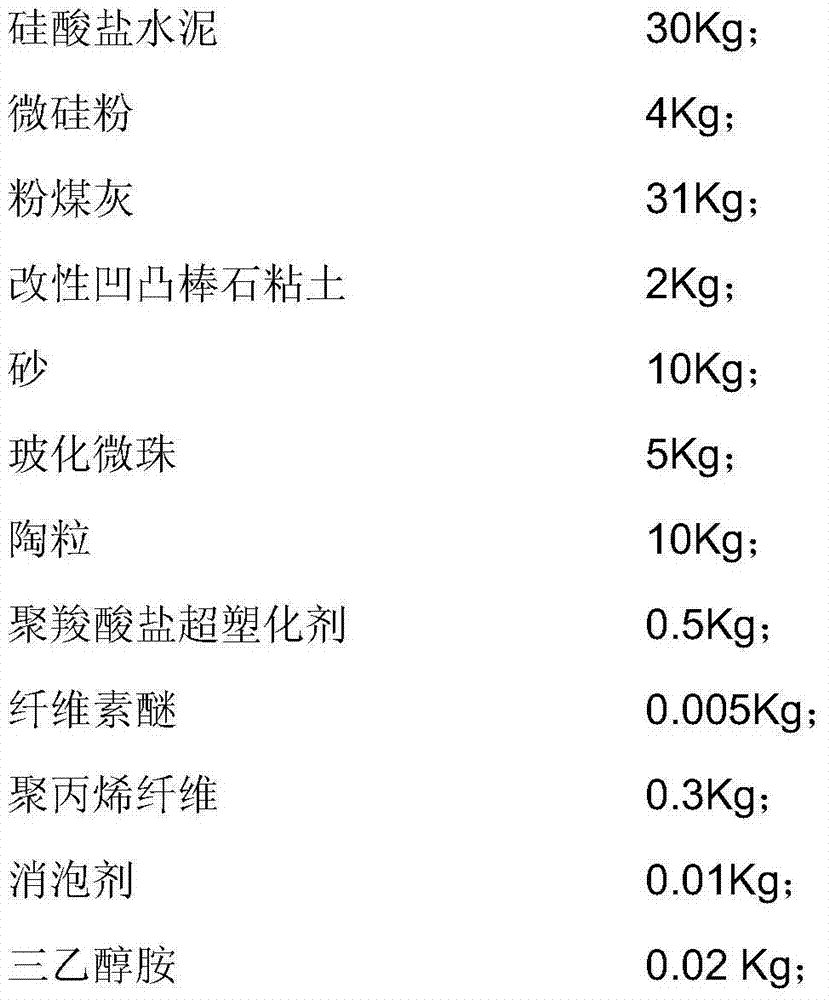

[0056] In this embodiment, the composite artificial stone structure slurry components include:

[0057]

[0058] The production method of the modified attapulgite clay composite artificial stone described in the present embodiment, the steps include:

[0059] Step 1, prepare color slurry, surface layer slurry, isolation middle layer slurry and structure slurry.

[0060] Step 2: Add the mo...

Embodiment 2

[0067] The steps of attapulgite clay modification are:

[0068] Step 1, add 3% (v / v) of γ-(methacryloyloxy)propyltrimethoxysilane (KH570) to high-viscosity attapulgite clay, and use hydrochloric acid to adjust its pH value to 3-4 standby;

[0069] Step 2, at room temperature, disperse the above slurry for 30 minutes with a disperser at a speed of 2500r / min;

[0070] Step 3, adjust the temperature to 60°C, and use 70r / min low-speed stirring for 7h;

[0071] In step 4, the above slurry is separated, dried, crushed and passed through a 200-mesh sieve to obtain modified attapulgite clay.

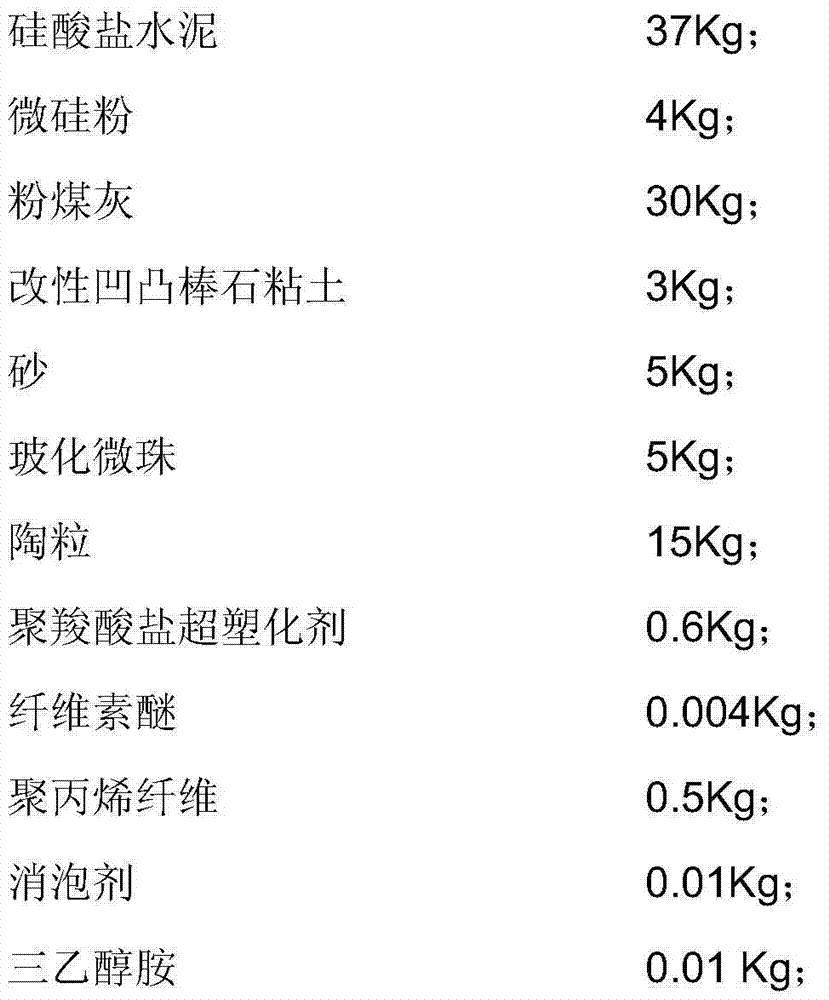

[0072] In this embodiment, the composite artificial stone slurry component includes:

[0073]

[0074] The production and preparation method of modified attapulgite clay composite artificial stone in this embodiment, the steps include:

[0075] Step 1, prepare color slurry, surface layer slurry, isolation middle layer slurry and structure slurry.

[0076] In step 2, the modified attapulg...

Embodiment 3

[0083] The steps of attapulgite clay modification are:

[0084] Step 1, add 3% (v / v) γ-aminopropyltriethoxysilane (KH550) to the high-viscosity attapulgite clay, and use hydrochloric acid to adjust its pH value to 3-4 for later use;

[0085] Step 2, at room temperature, disperse the above slurry for 30 minutes with a disperser at a speed of 3000r / min;

[0086] Step 3, adjusting the temperature to 60°C, and stirring at a low speed of 100r / min for 6h;

[0087] In step 4, the above slurry is separated, dried, crushed and passed through a 200-mesh sieve to obtain modified attapulgite clay.

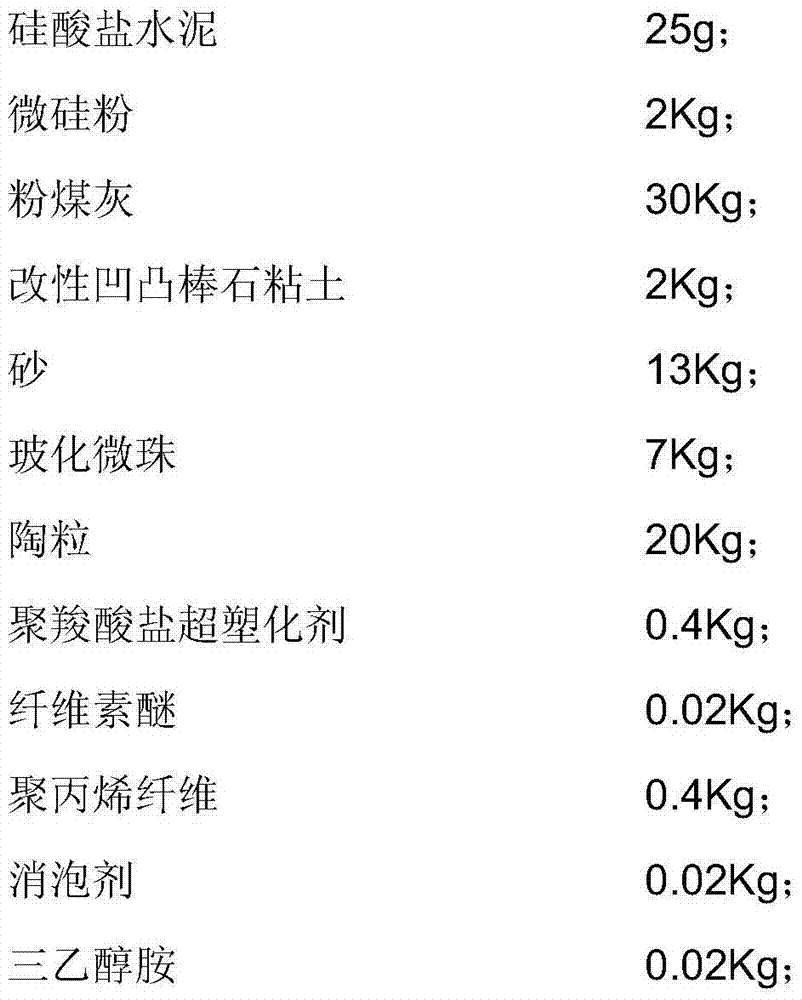

[0088] Among them, the composite artificial stone slurry components include:

[0089]

[0090] The production and preparation method of modified attapulgite clay composite artificial stone in this embodiment, the steps include:

[0091] Step 1, prepare color slurry, surface layer slurry, isolation middle layer slurry and structure slurry.

[0092] Step 2: Add the modified attapulgite cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com