Lasting type anti-fogging polyethylene film master batch

A polyethylene film and anti-fog technology, applied in the field of polyethylene resin composition, can solve the problems of not meeting application requirements, poor film discharge, poor compatibility, etc., achieving a simple and easy preparation method and avoiding material slippage , Environmental pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

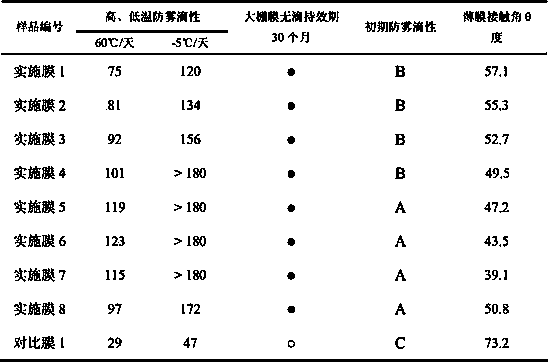

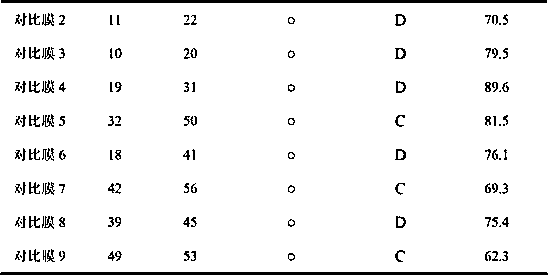

Examples

Embodiment 1

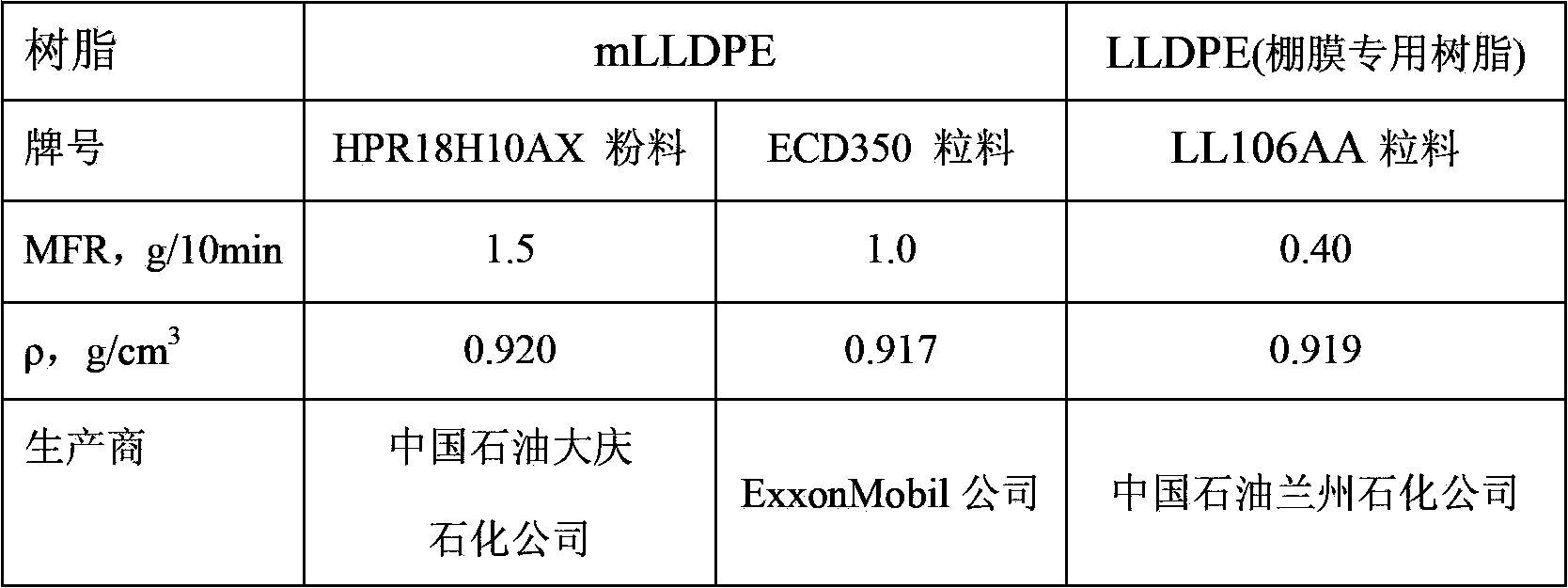

[0045] (1) Preparation of mLLDPE grafts: According to the weight percentage of mLLDPE, put 0.03 parts of DCP and 0.1 parts of acetone into a beaker and mix; then mix the mixed solution with 100 parts of mLLDPE (HPR18H10AX), 2.5 parts of methacrylic acid Put methyl ester (MMA) together in a 10L high-speed mixer, and mix at high speed for 3 minutes; finally, add the mixed material into the Φ67 twin-screw extruder, and the reaction temperature (°C) of each section of the screw is: 170, 175, 180 , 190, 200, 200, 195, 180, 175; after melt-grafting reaction for 6 minutes, extrude, cool, and granulate to obtain mLLDPE-g-MMA grafts (grafting rate: 0.7%).

[0046] (2) Preparation of mLLDPE anti-fogging film masterbatch: put 100 parts of mLLDPE (HPR18H10AX) and 1.2 parts of mLLDPE-g-MMA graft (grafting rate: 0.7%) into a 10-liter high-speed mixer, Mix at high speed for 5 minutes; then add 5.5 parts of polyoxyethylene sorbitan monolaurate (T-20), 1.5 parts of polyvinyl alcohol, 0.1 part ...

Embodiment 2

[0048] (1) Preparation of mLLDPE-g-MMA graft: Same as Example 1.

[0049] (2) Preparation of mLLDPE anti-fogging film masterbatch: put 100 parts of mLLDPE (HPR18H10AX) and 1.4 parts of mLLDPE-g-MMA graft (grafting rate: 0.7%) into a 10-liter high-speed mixer, Mix at high speed for 5 minutes; then add 6.1 parts of polyoxyethylene sorbitan monolaurate (T-20), 1.7 parts of polyvinyl alcohol, 0.15 parts of antioxidant 1010, 0.15 parts of calcium stearate, and mix at high speed for 5 minutes; The mixed material is fed into the Φ67 twin-screw extruder, and the reaction temperature (°C) of each section of the screw is: 170, 180, 190, 200, 210, 220, 200, 190, 180; after 4 minutes of reaction, extrude and cool and granulation to obtain the mLLDPE anti-fogging film masterbatch.

Embodiment 3

[0051] (1) Preparation of mLLDPE-g-MMA graft: Same as Example 1.

[0052] (2) Preparation of mLLDPE anti-fogging film masterbatch: Put 100 parts of mLLDPE (HPR18H10AX) and 1.7 parts of mLLDPE-g-MMA graft (grafting rate: 0.7%) into a 10-liter high-speed mixer, Mix at high speed for 5 minutes; then add 6.7 parts of polyoxyethylene sorbitan monolaurate (T-20), 1.9 parts of polyvinyl alcohol, 0.15 parts of antioxidant 1010, 0.15 parts of calcium stearate, and mix at high speed for 5 minutes; The mixed material is fed into the Φ67 twin-screw extruder, and the reaction temperature (°C) of each section of the screw is: 170, 180, 190, 200, 210, 220, 200, 190, 180; after 4 minutes of reaction, extrude and cool and granulation to obtain the mLLDPE anti-fogging film masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com