Ultra-large dual-layer steel plate concrete silo prestressed technology and structure of ultra-large dual-layer steel plate concrete silo

A steel plate concrete and super-large technology, applied in the storage field, can solve the problems of bottom corridor deformation, vertical load increase, and high overall cost, and achieve the effect of increasing construction speed, reducing overall cost, and high overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

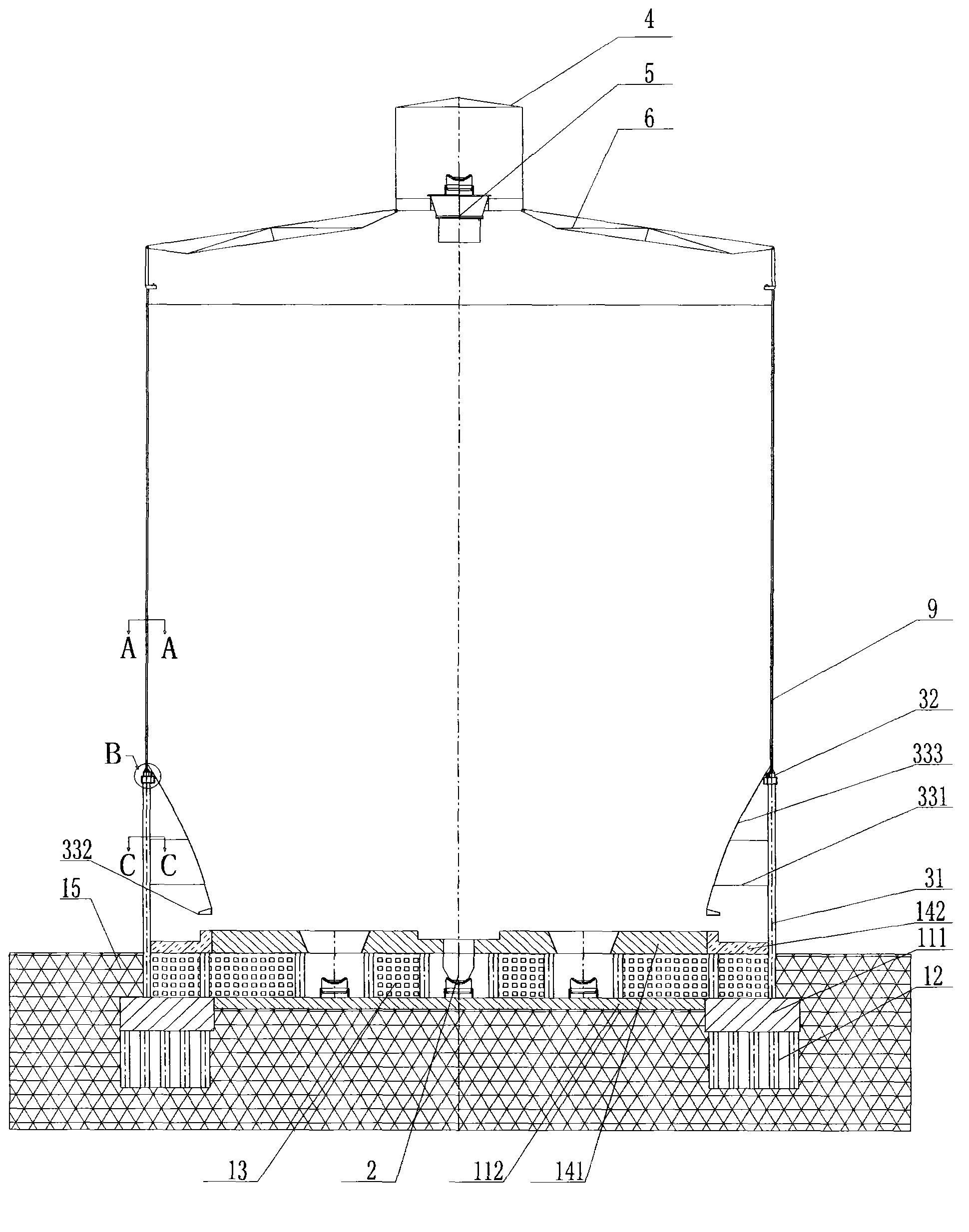

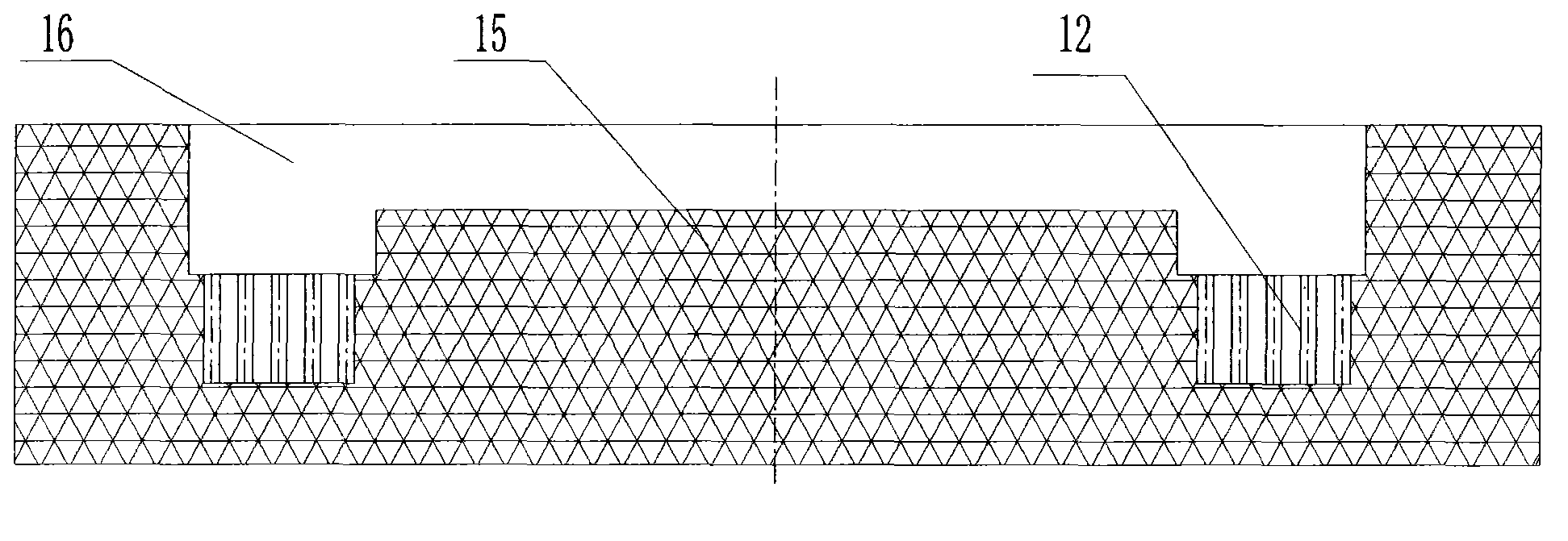

[0036] A super-large double-layer steel plate concrete silo prestressing process is as follows: first excavate the foundation pit 16, and drive the pile foundation 12, such as image 3 Shown; excavate the original soil layer 15, when the underground water content is high, carry out the overall vacuum pumping and compaction of the base surface after the excavation, the base plate 11 is fixed on the original soil layer 15 by the pile foundation 12, as Figure 4 shown.

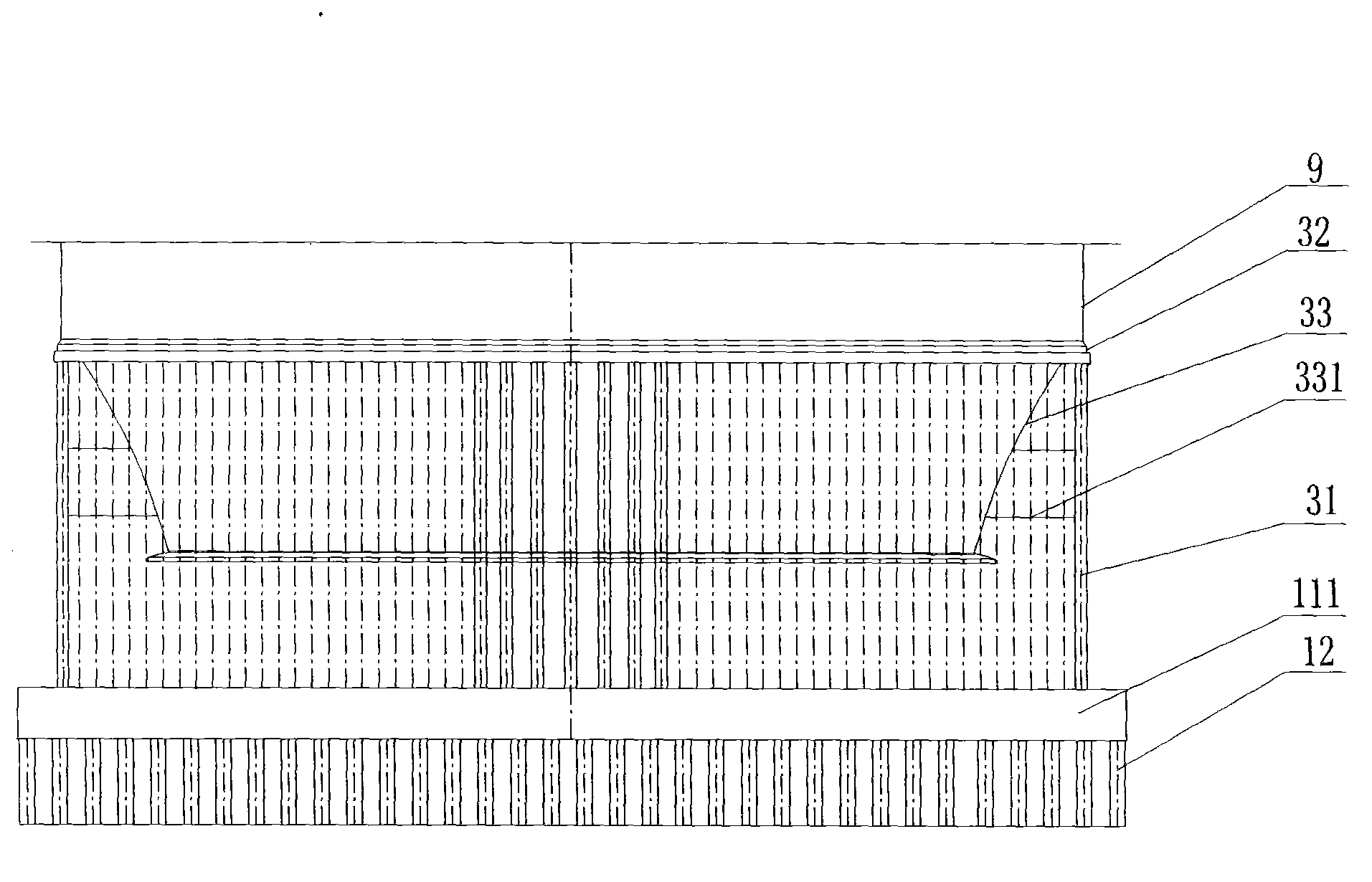

[0037] Installation cylinder assembly 3 - steel pipe pillar 31, combined annular support seat 32, steel structure cone 33, double-layer annular steel plate interlayer 34, canopy 6, central blanking cylinder 5, belt trestle 4, steel pipe pillar 31 is set on the foundation 1 on the base plate 11, such as figure 2 As shown; the double-layer annular steel plate interlayer 34 is connected with the steel pipe pillar 31 through the combined annular support seat 32, and the steel structure cone 33 is set at the combine...

Embodiment 2

[0045] A super-large double-layer steel plate concrete silo prestressing process is as follows: first excavate the foundation pit 16, and drive the pile foundation 12, such as image 3 Shown; excavate the original soil layer 15, when the underground water content is high, carry out the overall vacuum pumping and compaction of the base surface after the excavation, the base plate 11 is fixed on the original soil layer 15 by the pile foundation 12, as Figure 4 shown.

[0046] Installation cylinder assembly 3 - steel pipe pillar 31, combined annular support seat 32, steel structure cone 33, double-layer annular steel plate interlayer 34, canopy 6, central blanking cylinder 5, belt trestle 4, steel pipe pillar 31 is set on the foundation 1 on the base plate 11, such as figure 2 As shown; the double-layer annular steel plate interlayer 34 is connected with the steel pipe pillar 31 through the combined annular support seat 32, and the steel structure cone 33 is set at the combine...

Embodiment 3

[0054] A super-large double-layer steel plate concrete silo prestressing process is as follows: first excavate the foundation pit 16, and drive the pile foundation 12, such as image 3 Shown; when excavating the original soil layer 15, when the underground water content is high, the overall vacuum pumping and compaction of the base surface after excavation is carried out, and the steel pipe pillar 31 in the silo shell assembly 3 is lengthened to replace the pile foundation 12 in the foundation 1, directly Fix the pile foundation 12, save the secondary pouring of the foundation slab 11, and form a super-large double-layer steel plate concrete silo without a foundation slab structure, such as Figure 8 shown.

[0055] Installation cylinder assembly 3 - steel pipe pillar 31, combined annular support seat 32, steel structure cone 33, double-layer annular steel plate interlayer 34, canopy 6, central blanking cylinder 5, belt trestle 4, steel pipe pillar 31 is set on the foundation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com