High-real-time quantitative ultrasonic detection method based on multi-angle stereo matching

A technology of stereo matching and ultrasonic testing, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of loss of real-time detection, time-consuming, and low degree of defect quantification, and achieve significant real-time detection capabilities and complete portability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

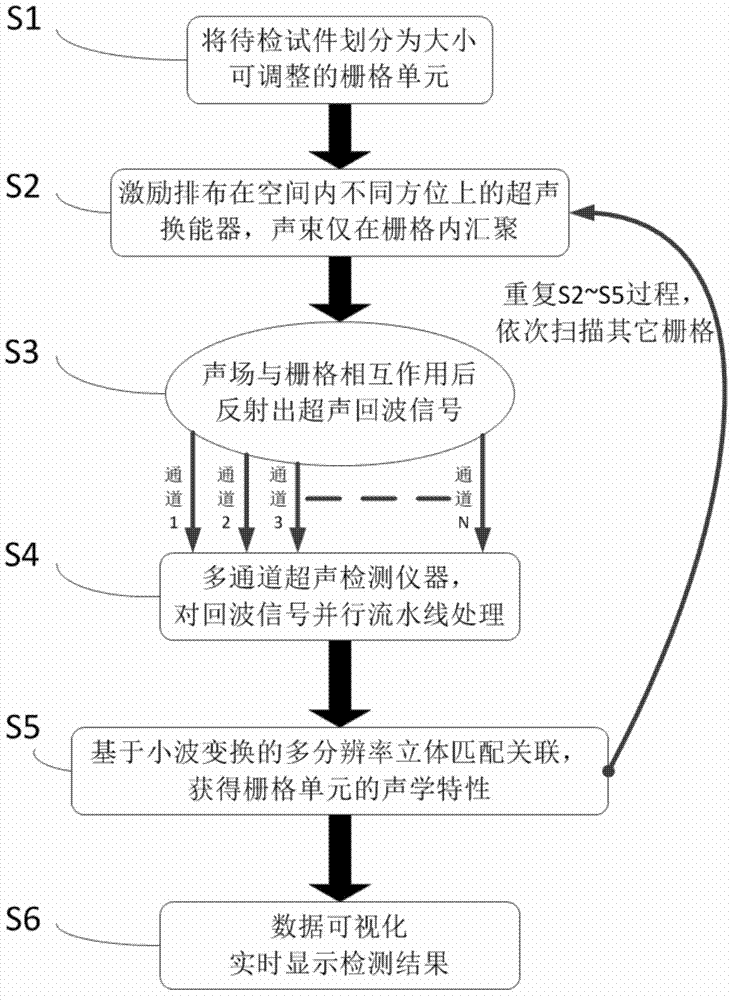

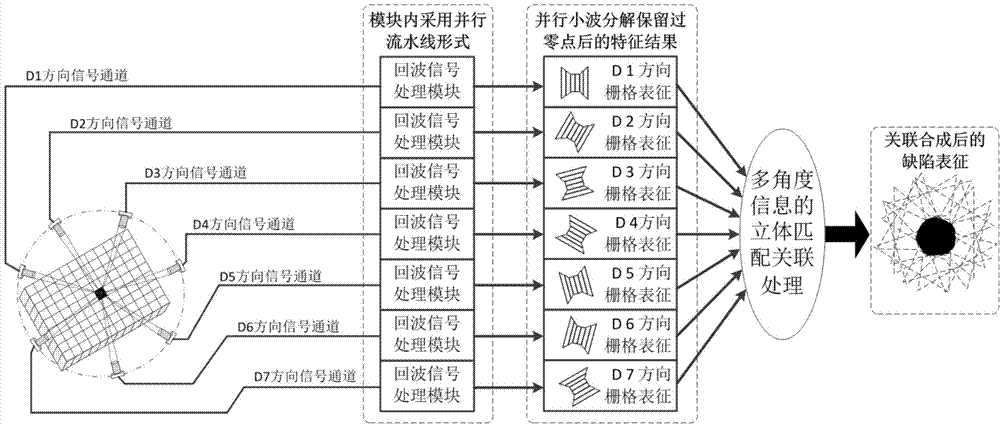

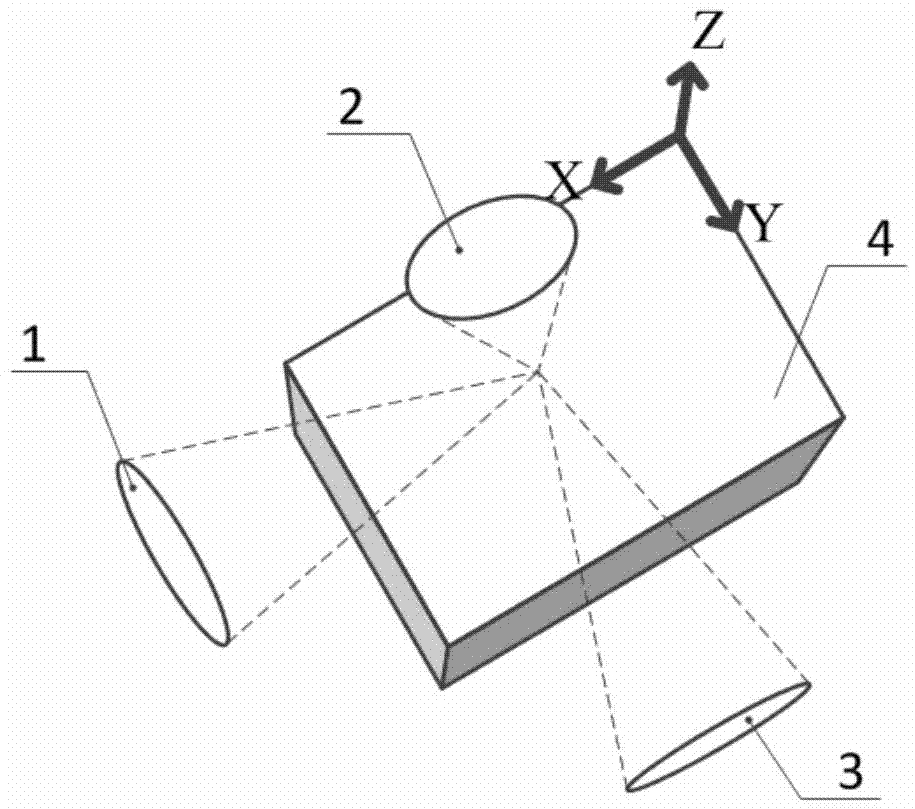

[0031] Such as figure 1As shown, the general process of the high-real-time quantitative ultrasonic testing method based on multi-angle stereo matching includes: S1 indicates that the test piece is divided into adjustable grid units, which are used as the basic unit for defect reconstruction and material characterization; Arrange two or more ultrasonic transducers in different orientations, adjust the attitude of the ultrasonic transducers, so that the sound beams of each ultrasonic transducer only converge in the grid unit space, and each beam of sound waves is transmitted from the ultrasonic transducer The sound path experienced by the transducer surface converging to the grid unit is the same; S2 indicates that each ultrasonic transducer is excited, and the sound waves emitted by them will form a sound field with the highest energy at the corresponding grid unit; S3 indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com