Structure of comprehensive type silicon epitaxy process photoetching alignment mark and manufacturing method

A technology of lithography alignment and silicon epitaxy, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of deformation and disappearance of lithography alignment marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the illustrated embodiment, the details are as follows:

[0030] The selective silicon epitaxy process refers to the growth of a single crystal on a silicon single crystal by adding a precursor containing chlorine atoms to the silicon source during the silicon epitaxial growth process, but not on a certain dielectric film. . Different dielectric films require different components of chlorine-containing precursors. Therefore, when multiple dielectric films exist on the same surface at the same time, silicon epitaxy can be grown on a certain dielectric film under a specific chlorine-containing precursor component. , while silicon epitaxy does not grow on other dielectric films.

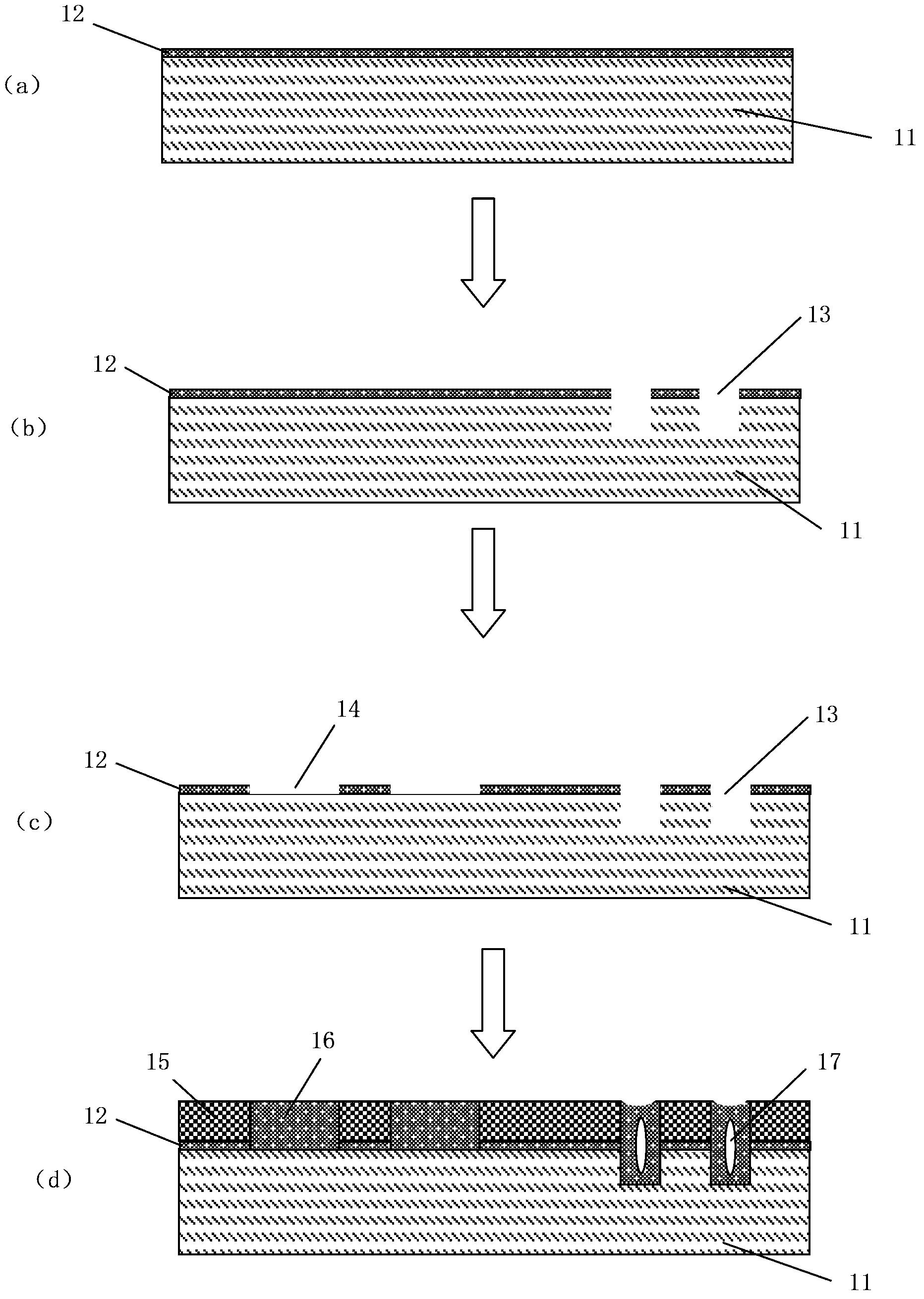

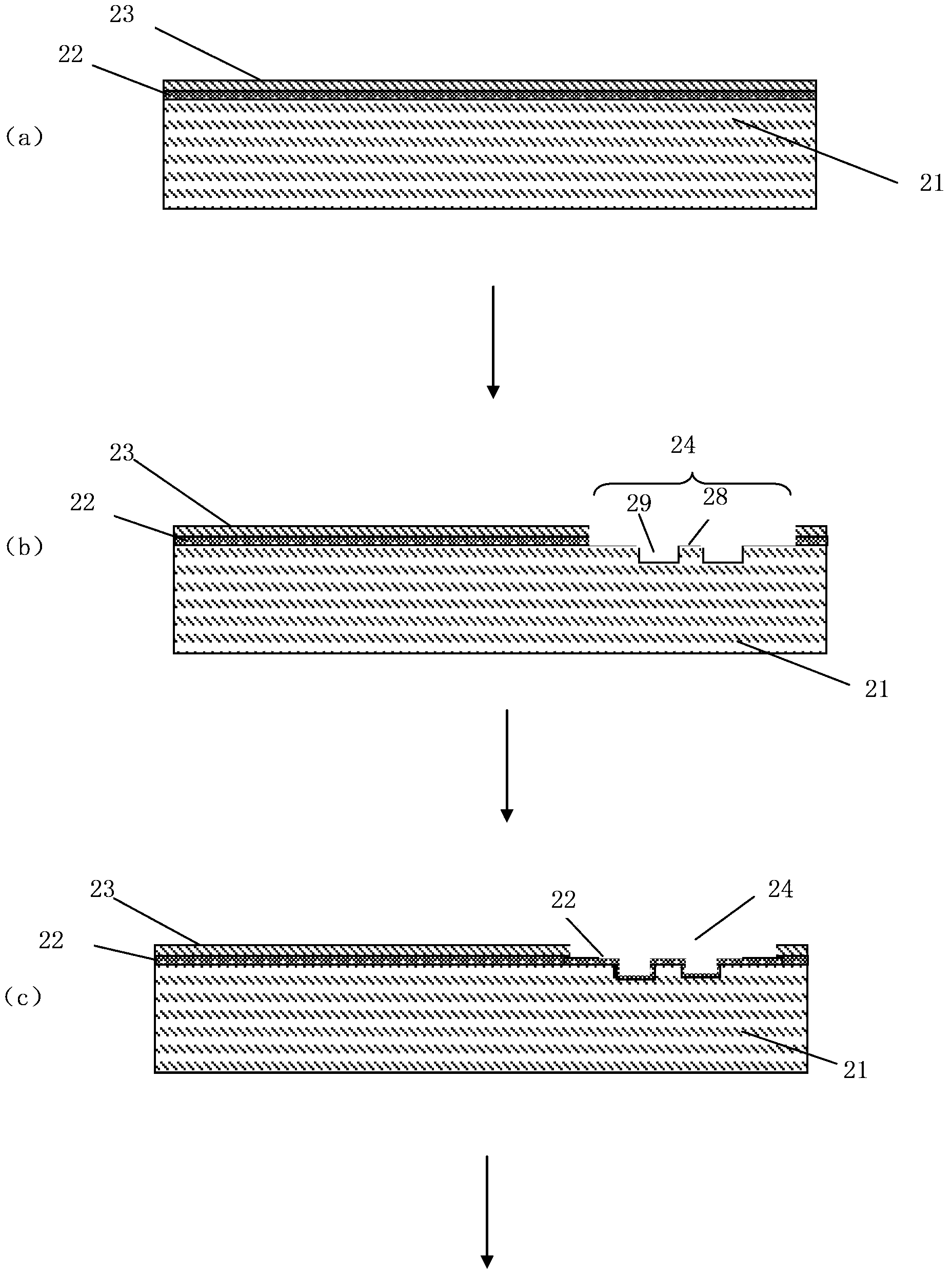

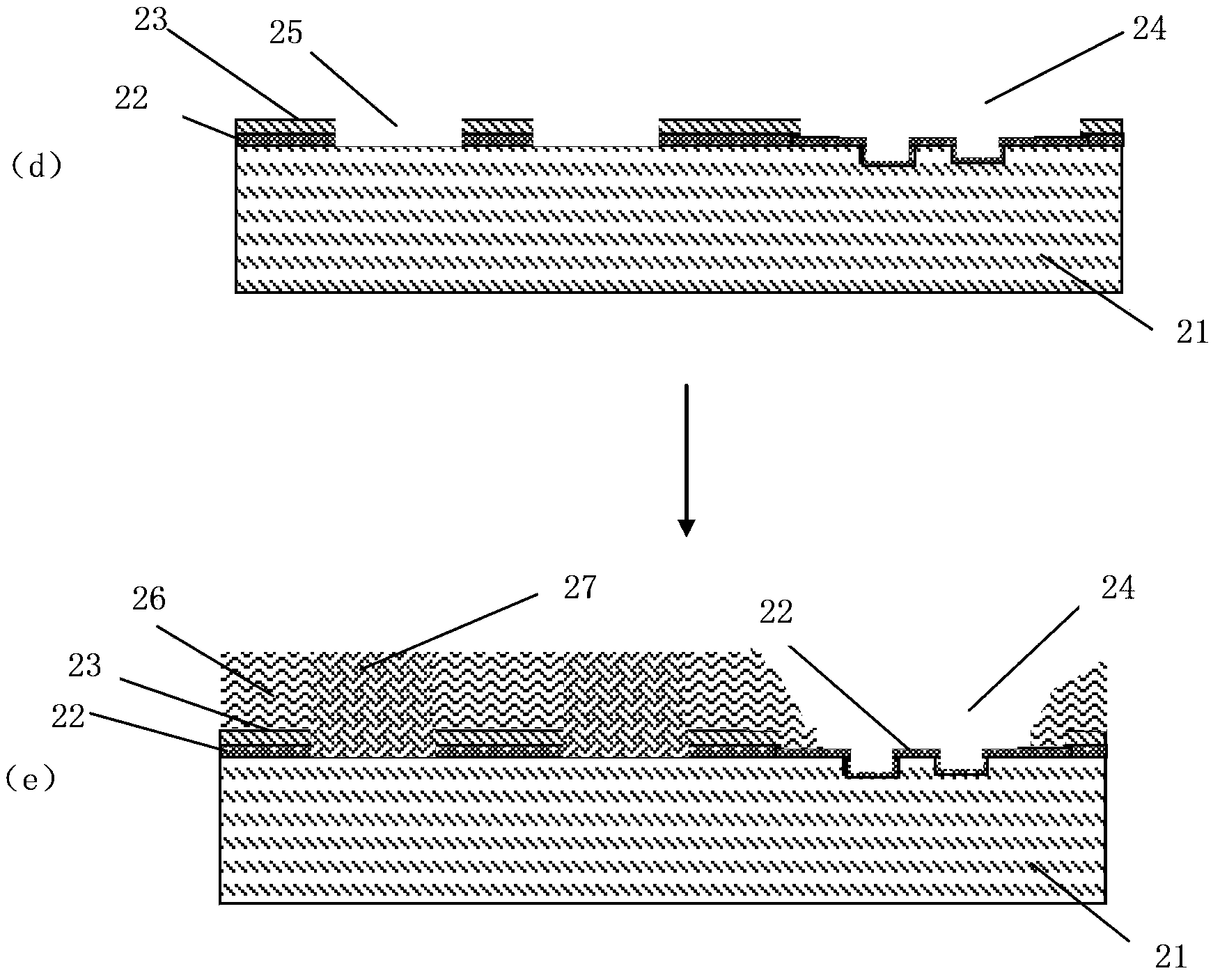

[0031] Utilizing the characteristics of the above-mentioned selective silicon epitaxial process, the present invention has produced the lithograp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com