Printed circuit board and method for manufacturing a printed circuit board

A technology for printed circuit boards and manufacturing methods, applied in the directions of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of uneven tin consumption, component offset, components cannot be accurately aligned, and reduce solder paste. The effect of layer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above and other objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention are listed below and described in detail in conjunction with the accompanying drawings.

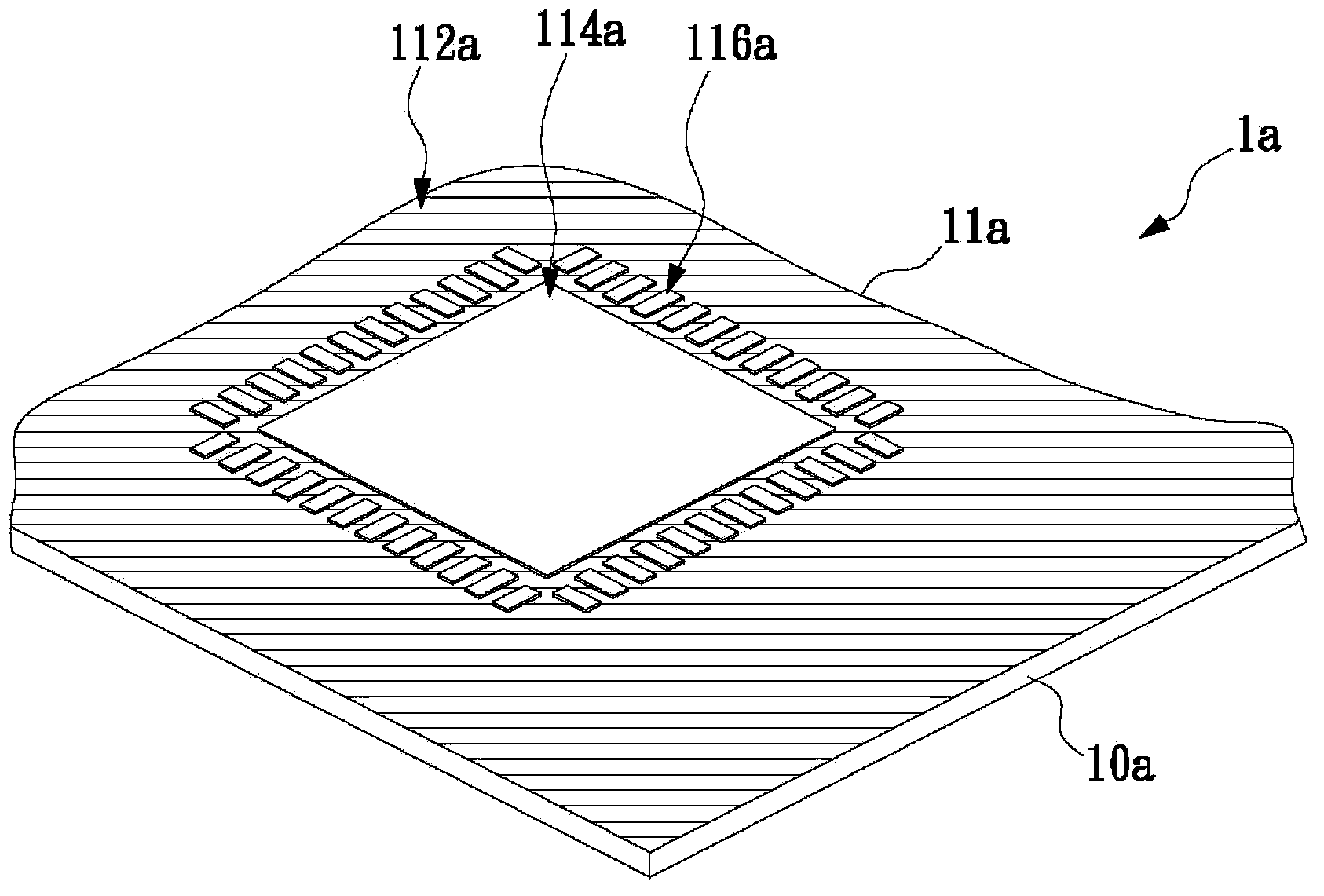

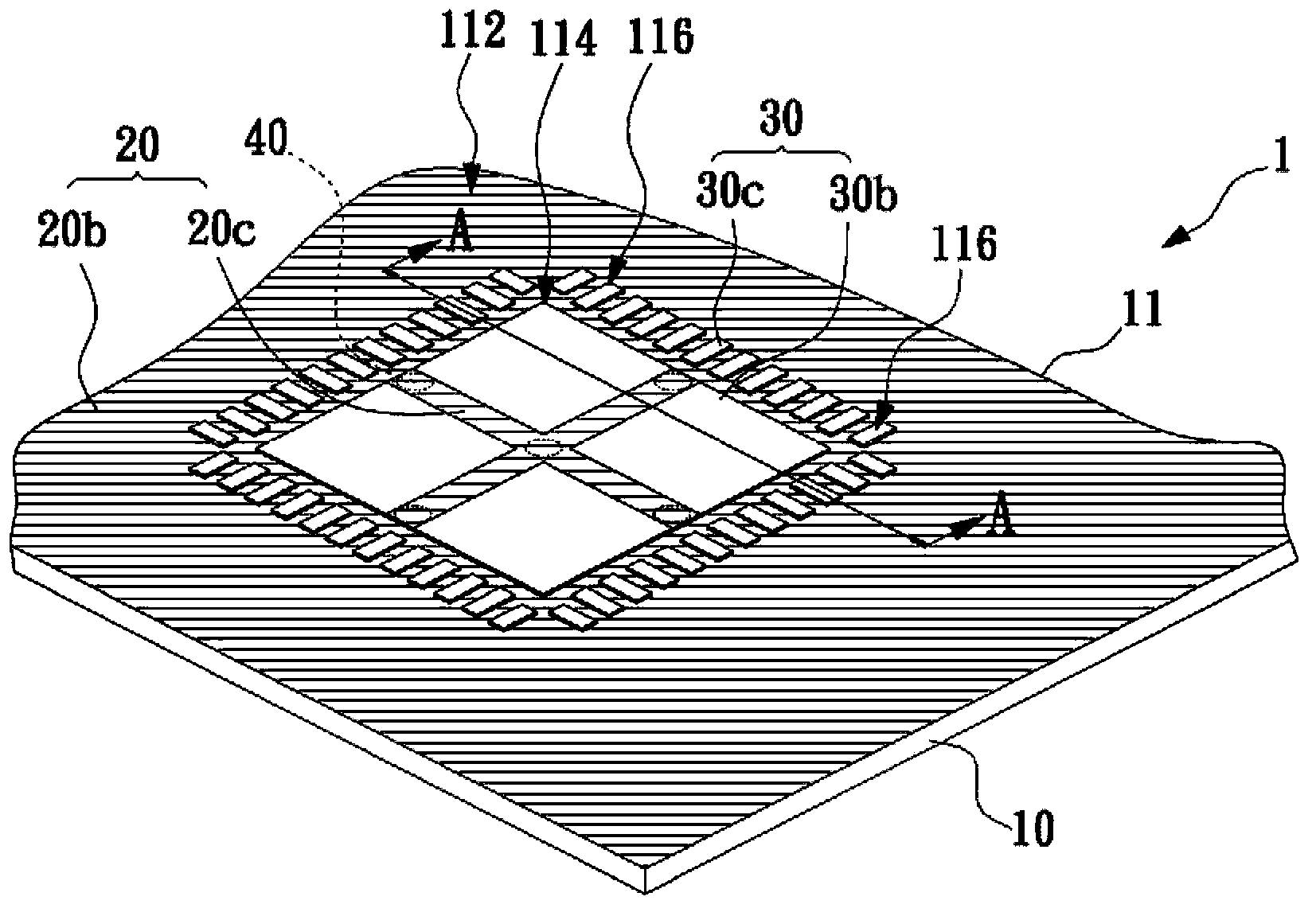

[0026] Please refer to the following figure 2 and image 3 The structure of the printed circuit board of the first embodiment of the present invention is schematically shown.

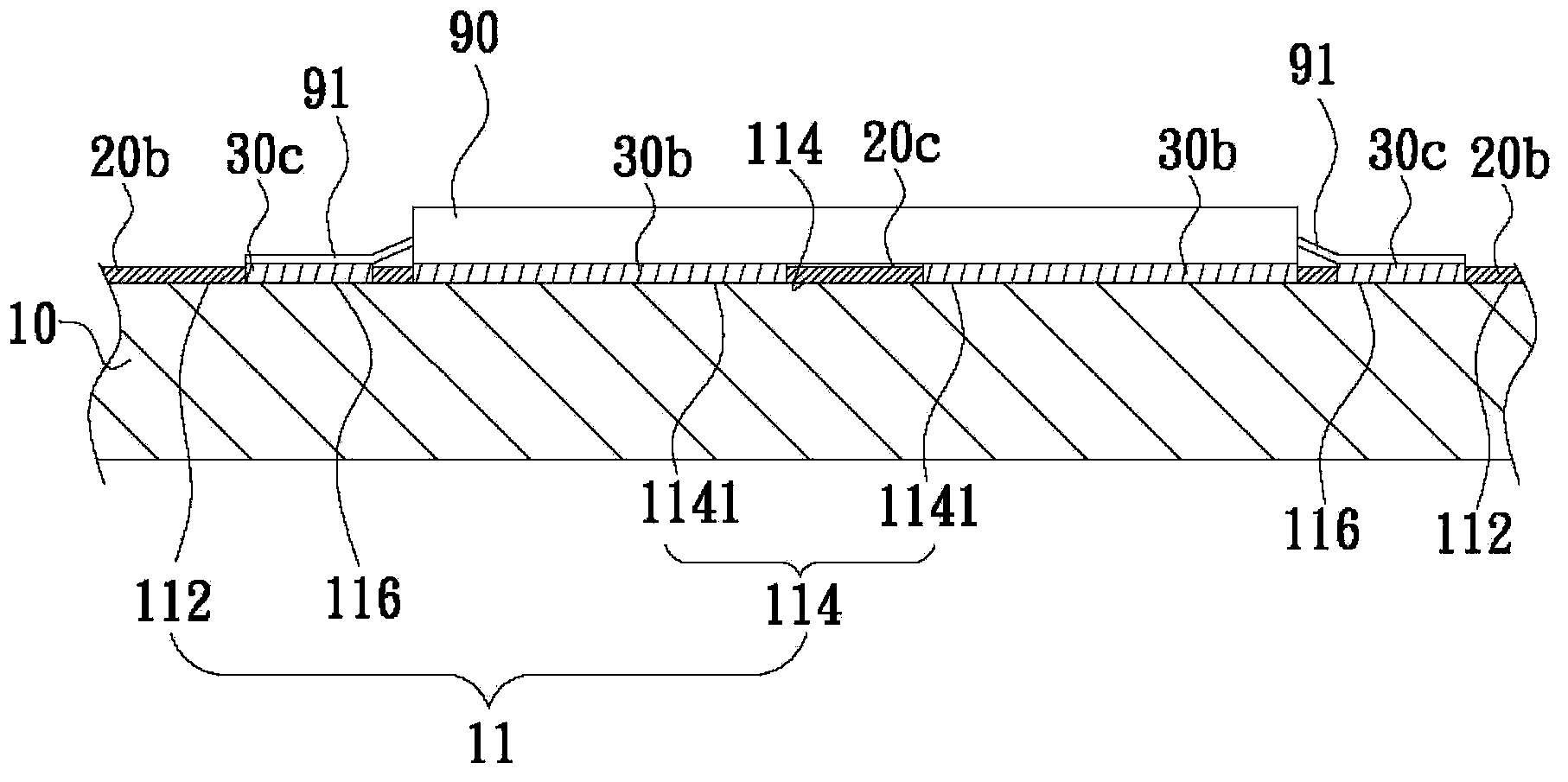

[0027] Such as figure 2 As shown, in one embodiment of the present invention, the printed circuit board 1 of the present invention includes a copper foil substrate 10, a solder resist layer 20, a solder paste layer 30 and at least one through hole 40, wherein the solder resist layer 20 includes a main anti- The solder layer 20b is isolated from the solder resist layer 20c, and the solder paste layer 30 includes a solder paste layer 30b in a sub-attachment area and a solder paste layer 30c in a pin area.

[0028] Such as figure 2 and image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com