Skeleton breaking machine

A bone-breaking and casing technology, applied in the direction of deboning shears/bone-crushing machines, etc., can solve the problems of easy occurrence of fine particles, uneven material size, affecting the treatment of animal bones, etc., to ensure shearing efficiency and reduce energy consumption. , to avoid the effect of cutting power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

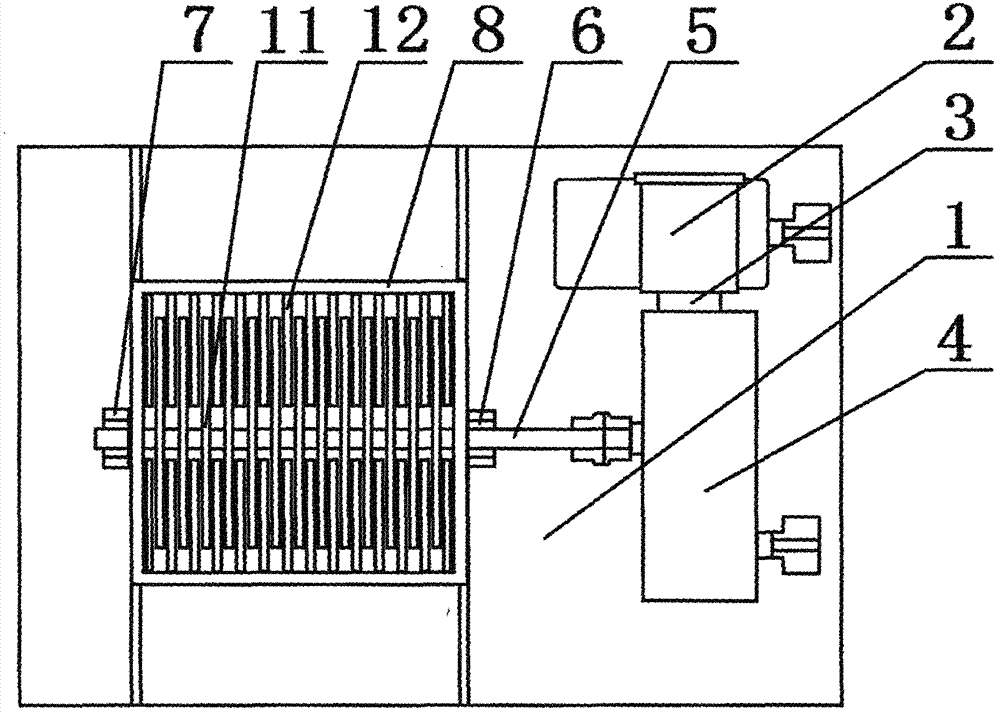

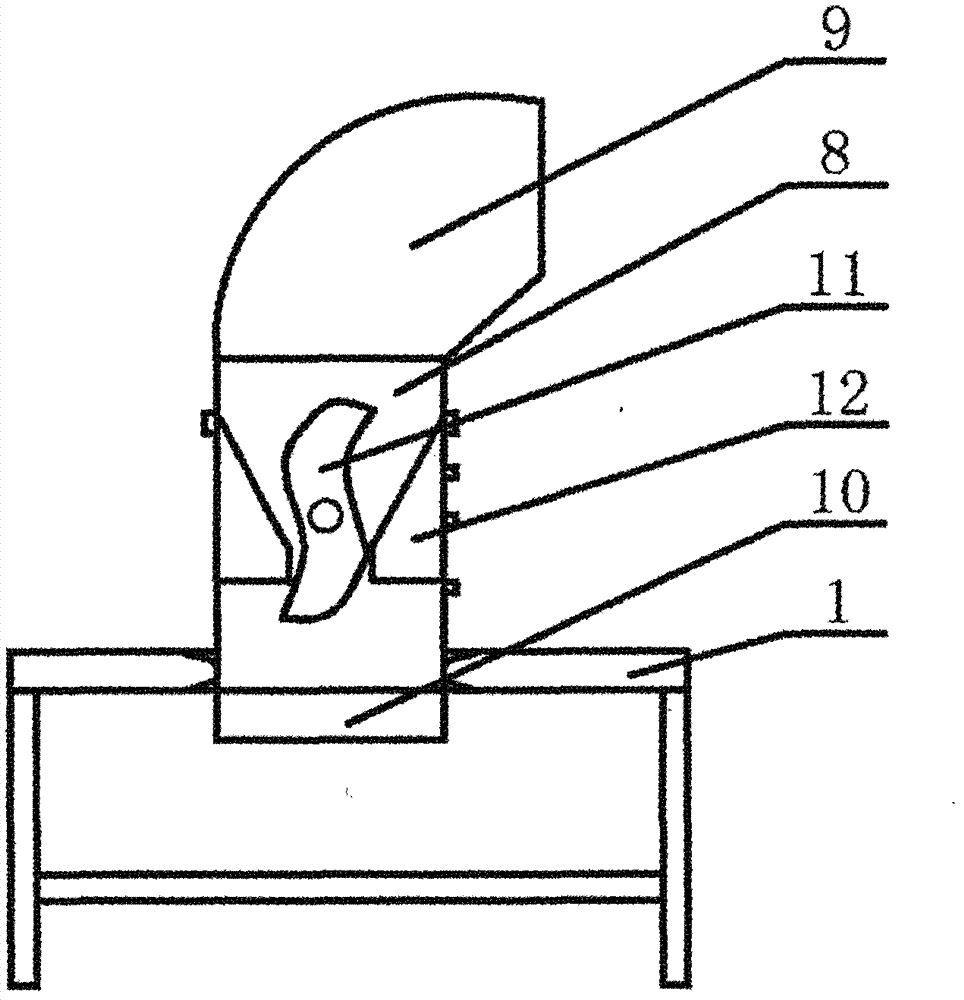

[0014] In the figure, 1-frame, 2-motor, 3-belt, 4-reducer, 5-spindle, 6-bearing, 7-bearing seat, 8-casing, 9-feeding hopper, 10-outlet, 11-moving knife, 12-fixed knife.

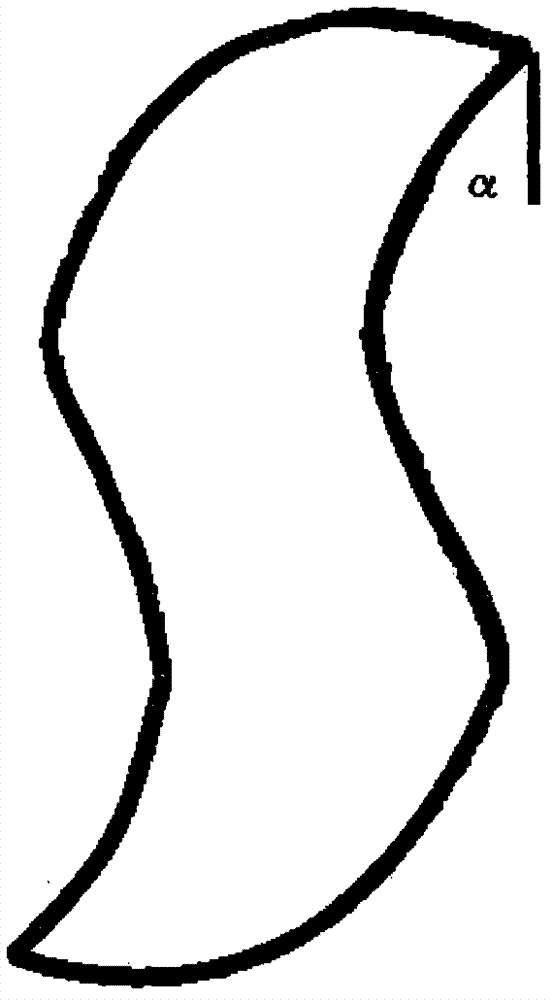

[0015] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the motor 2, the reducer 4 and the casing 8 are located on the frame 1, the motor 2 is connected to the reducer 4 through the belt 3, the reducer 4 is connected to the main shaft 5, the main shaft 5 runs through the casing 8, and passes through the bearing 6 and The bearing sleeve 7 is fixed on the casing 8, the upper part of the casing 8 is connected with the feeding hopper 9, the lower part is connected with the discharge port 10, and the thirteen moving knives 11 are set on the main shaft 5, and the main shaft 5 is arranged in a spiral shape. The knife 11 has an axially symmetrical structure, and the feeding angle α is 10°-45°. Two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com