Immersed-type ultrafiltration membrane pool and on-line chemical cleaning method thereof

An ultrafiltration membrane and submerged technology, which is applied in the field of submerged ultrafiltration membrane pools, can solve the problems of low flux of submerged ultrafiltration membranes, high dosage of chemical washing, and frequent operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

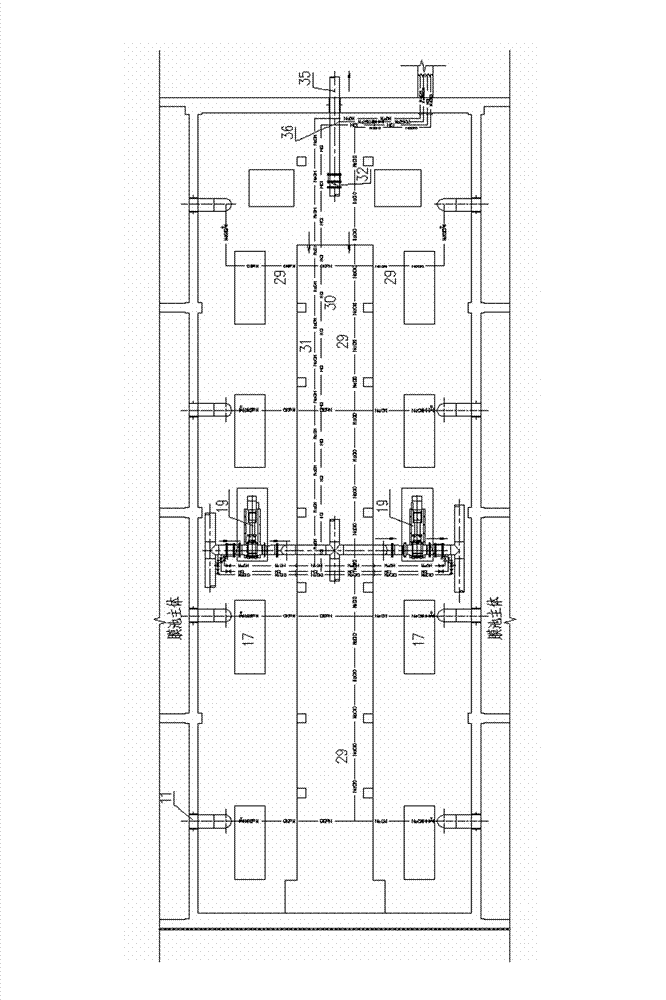

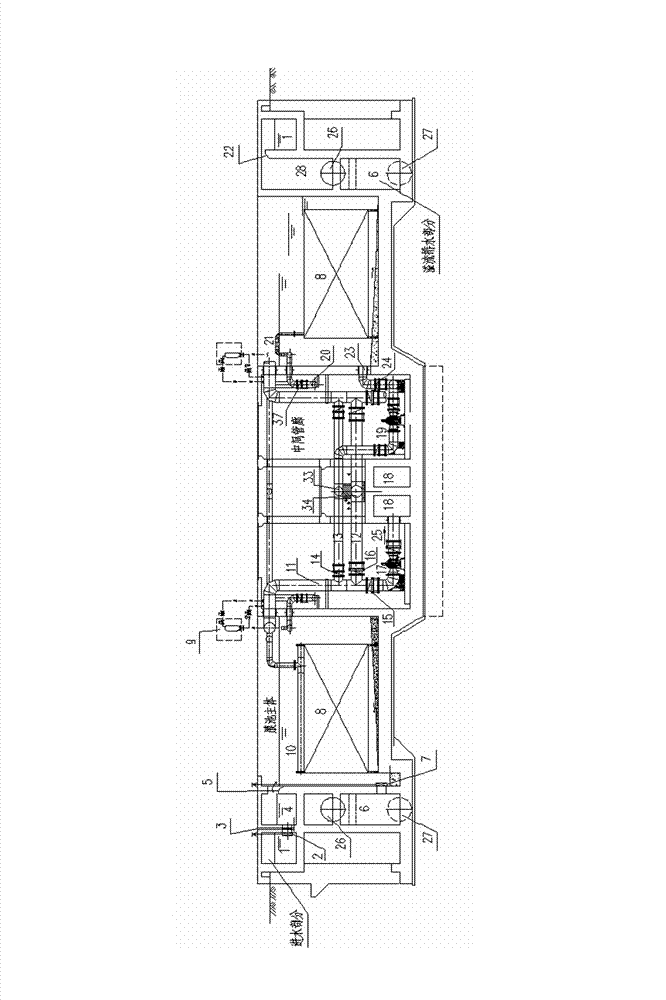

[0020] The present invention will be further described below in conjunction with accompanying drawings and examples.

[0021] The types of agents selected for chemical cleaning of submerged ultrafiltration membrane tanks, cleaning cycle, and cleaning time are related to factors such as raw water quality, operating environment, and the conditions of the membrane equipment itself. You can refer to the parameters provided by the membrane manufacturer, but the final results need to be determined by the pilot test results. Sure. In the present invention, sodium hypochlorite (NaClO) solution is used for maintenance cleaning, and the sequence for restorative cleaning is alkaline cleaning followed by pickling. The pickling uses hydrochloric acid (HCl) solution, and the alkaline cleaning uses sodium hydroxide (NaOH) solution and sodium hypochlorite (NaClO). solution, and sodium sulfite (Na 2 SO 3 ) solution neutralization as an example to illustrate the online maintenance and restora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com