Automatic molding technique for tungsten alloy holding-up hammer and device for realizing technique

An automatic forming, tungsten alloy technology, applied in the application of ultra-high pressure process and other directions, can solve the problem of automatic feeding and forming method of tungsten alloy top hammer not found, to avoid weighing inaccurate or block bridging, avoid damage, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

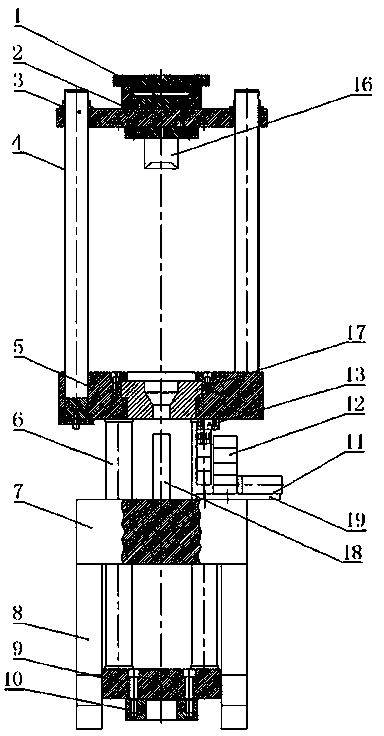

[0036] The upper limit device is a buffer limit cylinder 14 located on both sides of the upper template. The buffer limit cylinder 14 includes a buffer cylinder, a buffer piston rod and an adjusting bolt. The buffer cylinder is installed on the upper template 2, and the buffer piston rod is vertically downward. The lower end of the buffer piston rod is threadedly connected with the adjusting bolt 15. The buffer piston rod of the buffer limit cylinder 14 is pressed against the female template to realize the lower limit that the upper die punches in the female template.

[0037] The lower limiting device is a lateral limiting cylinder 11 horizontally installed on the middle template, the cylinder body of the lateral limiting cylinder 11 is fixed on the middle template 7 through a backing plate 19, and the end of the piston rod of the lateral limiting cylinder 11 passes through The T-shaped block is connected to the lateral limit slide block 12, and some lower limit blocks A are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com