A dual excitation ultrasonic elliptical vibration machining device

An elliptical vibration and processing device technology, applied in the field of machining, can solve the problems of poor sensitivity of rigid connection, lack of displacement amplification function, poor air cooling effect, etc., to achieve large magnetostrictive strain, easy installation and clamping in, The effect of transferring large displacements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

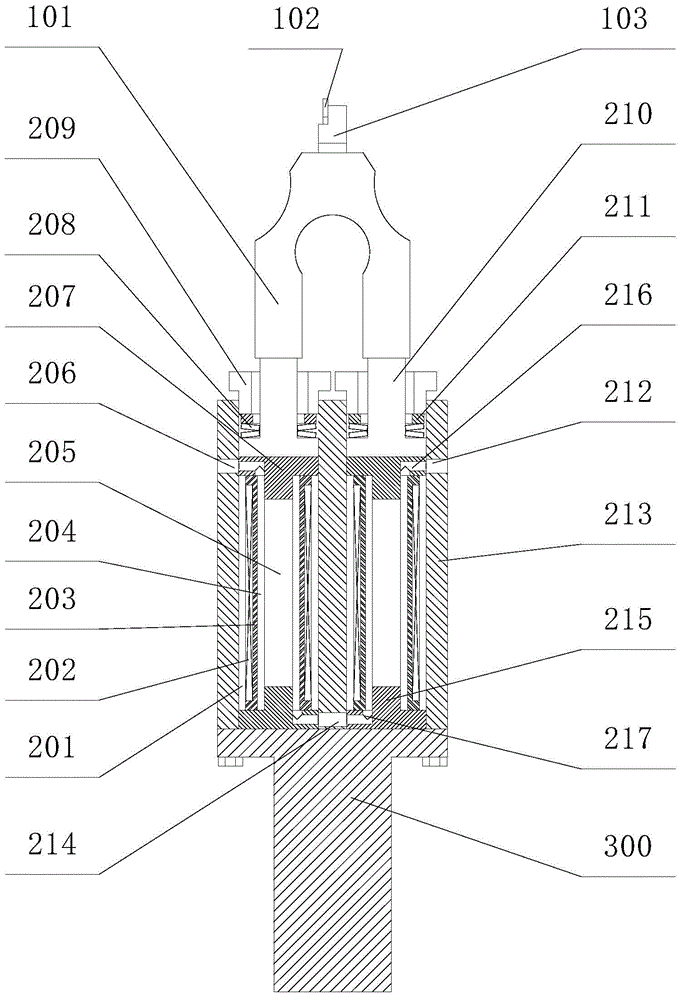

[0022] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

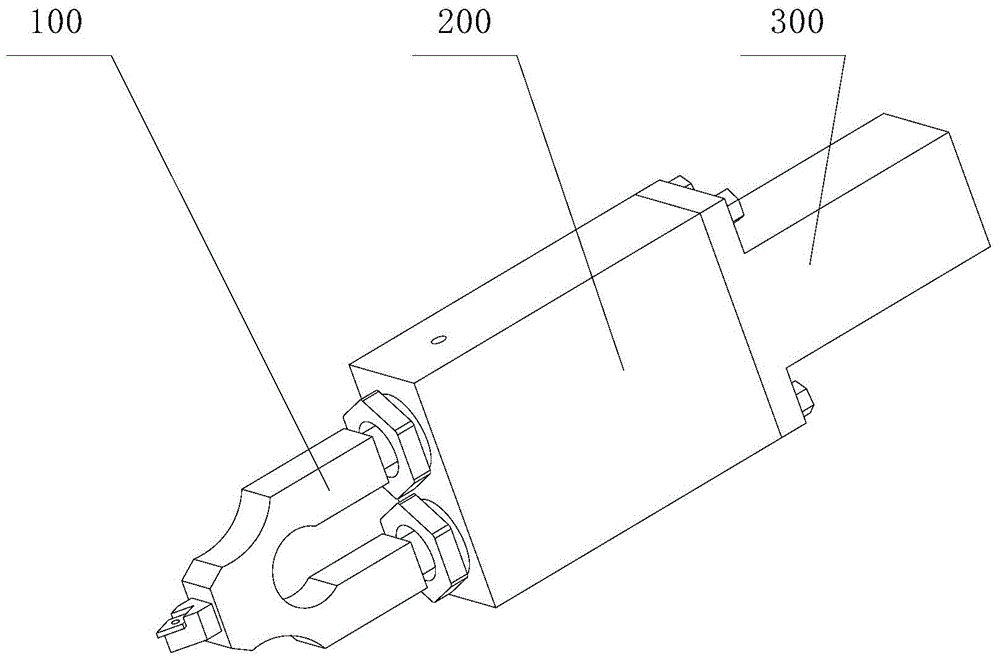

[0023] A dual-excitation ultrasonic elliptical vibration processing device provided by the present invention includes a front cutter 100, a vibration generating unit 200, and a rear tool handle 300. The vibration generating unit 200 includes two sets of giant magnetostrictive transducers arranged in parallel, and each set of ultra- The magnetostrictive transducer comprises giant magnetostrictive rods 205 made of giant magnetostrictive material. The present invention uses giant magnetostrictive materials to make giant magnetostrictive transducers. Compared with transducers using piezoelectric materials in the prior art, it has the advantages of large magnetostrictive strain, high output power, fast response speed, and high load capacity. Strong and other significant advantages.

[0024] see figure 2 , a schematic structural diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com