Device and method for driving monodisperse micro-droplet to spray and solidify based on giant magnetostriction

A technology of giant magnetostriction and giant magnetostrictive rods, which is applied in the field of devices and methods based on giant magnetostriction-driven monodisperse micro-droplet injection and solidification, and can solve the problems affecting the effect of piezoelectric ceramic droplet injection, piezoelectric Problems such as the permanent disappearance of ceramic polarization and the difficulty of miniaturization of the droplet ejection system have achieved the effects of easy miniaturization design, large output force, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

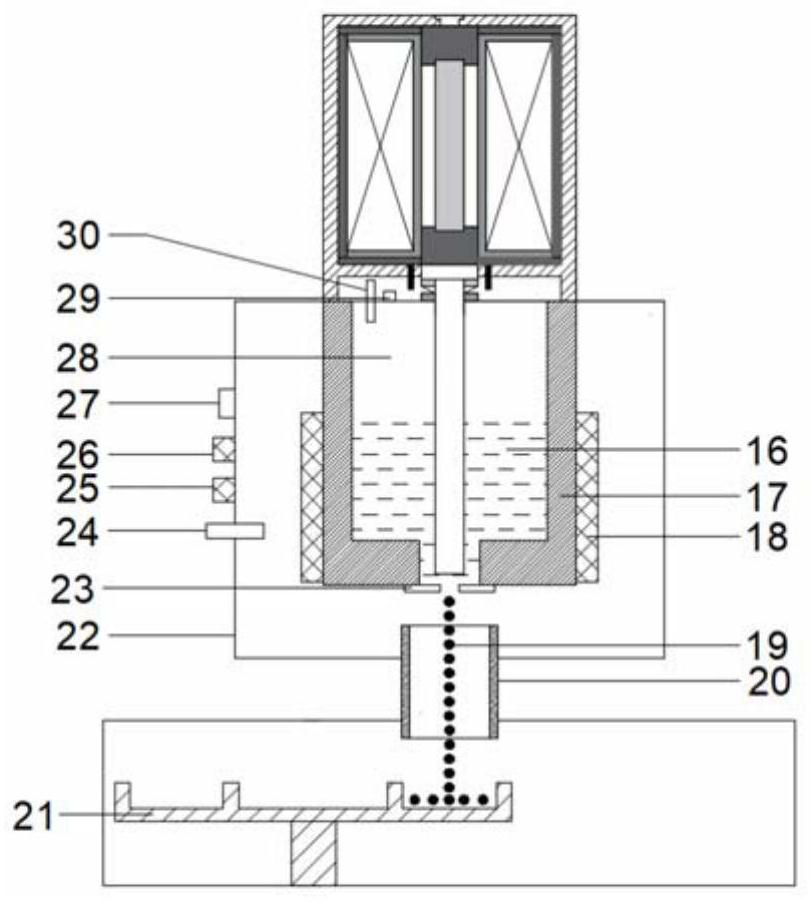

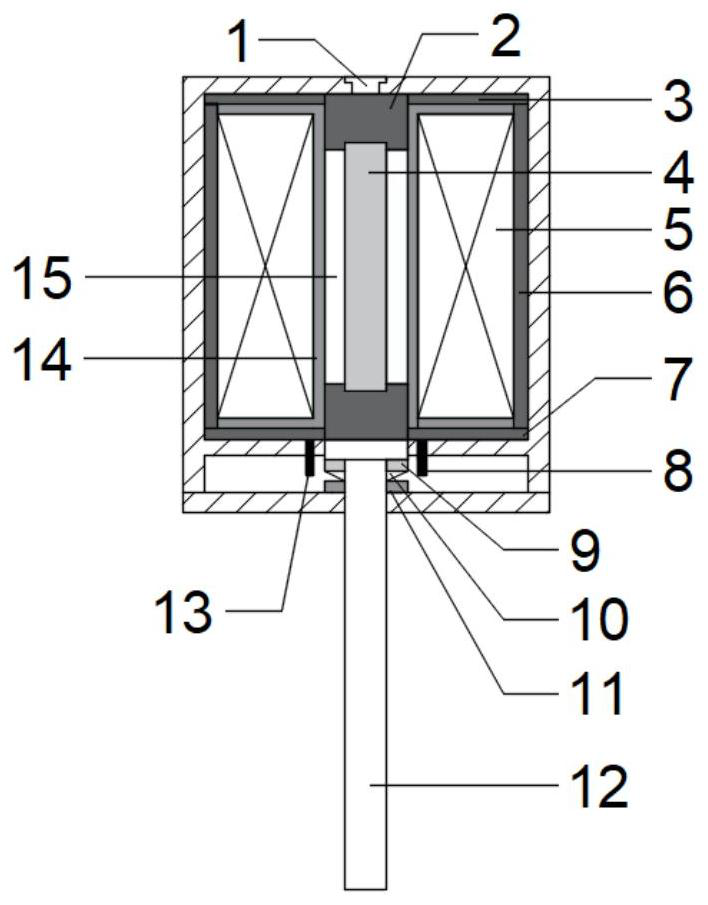

[0043] Such as Figure 1-2 As shown, the present invention provides a device based on giant magnetostrictive driven monodisperse micro-droplet ejection and solidification, comprising: an upper casing 22, a lower casing, and a giant magnetostrictive device placed above the upper casing 22 outside. The micro-displacement driver, the crucible 17 placed in the upper housing 22 and the particle collection area placed at the bottom of the lower housing, the crucible 17 is placed on the top of the particle collection area, and the giant magnetostrictive micro-displacement driver is located on the top of the crucible 17.

[0044] The crucible 17 is provided with a crucible cavity 28 for containing the melt 16; the crucible 17 is provided with a transmission rod 12 connected to the giant magnetostrictive driver, and the position where the transmission rod 12 is connected to the top of the crucible 17 is sealed by a dynamic sealing ring, and the transmission The lower end of the rod 12 ...

Embodiment 2

[0051] On the basis of embodiment 1, the present invention also provides a kind of method based on giant magnetostriction driven monodisperse droplet ejection and solidification, comprising the following steps:

[0052] S1, charging: put the metal material to be melted into the crucible cavity 28 of the crucible 17 in the upper housing 22 and then seal it; wherein, the amount of metal material loaded into the crucible cavity 28 is the crucible cavity 28 About two-thirds of the volume;

[0053] S2. Low vacuum and gas washing: Use the mechanical pump 25 and the diffusion pump 26 to vacuum the crucible 17, the upper casing 22 and the lower casing, turn on the mechanical pump 25 to pump low vacuum to below 5Pa, and fill it with high-purity inert protective gas , and then pumped to below 5Pa, this operation was repeated 3 times to ensure that the oxygen content in all shells was lower than 10ppm; vacuuming and scrubbing were to reduce the oxygen content and prevent the metal from h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com