Method of preparing biaryl compounds in pure water

A compound and pure water technology, applied in the direction of preparation of amino compounds from amines, preparation of organic compounds, organic chemical methods, etc., to achieve the effect of solving difficult reactions, wide application prospects, and rapid reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 14

[0014] The preparation of embodiment 14-phenyl anisole

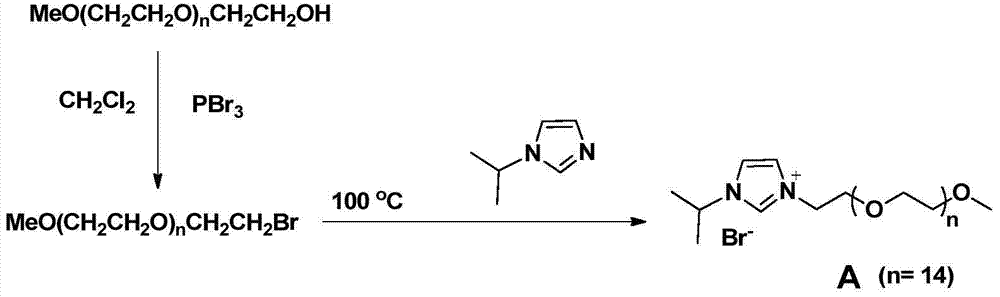

[0015] Add palladium acetate (0.0025 mmol), imidazolium salt A (0.01 mmol), 4-bromoanisole (0.5 mmol), phenylboronic acid (0.75 mmol), triethylamine (1.0 mmol) and water (1 mL) to the circle in sequence In a bottom flask, the reaction was stirred at 100°C for 5 minutes. After the reaction was completed, 10 mL of saturated brine was added to quench the reaction, the reaction mixture was extracted with 10 mL of ethyl acetate for 3 times, the organic phase was combined and concentrated to obtain a crude product, and the target product was obtained by column chromatography (eluent was petroleum ether). product structure through 1 H NMR and mass spectral identification. The isolated yield was 98%.

Embodiment 24

[0016] The preparation of embodiment 24-phenylnitrobenzene

[0017] Add palladium acetate (0.0025 mmol), imidazolium salt A (0.01 mmol), 4-bromonitrobenzene (0.5 mmol), phenylboronic acid (0.75 mmol), triethylamine (1.0 mmol) and water (1 mL) to the circle in sequence In a bottom flask, the reaction was stirred at 100°C for 5 minutes. After the reaction was completed, 10 mL of saturated brine was added to quench the reaction, the reaction mixture was extracted with 10 mL of ethyl acetate for 3 times, the organic phase was combined and concentrated to obtain a crude product, and the target product was obtained by column chromatography (eluent was petroleum ether). product structure through 1 H NMR and mass spectral identification. The isolated yield was 98%.

Embodiment 34

[0018] The preparation of embodiment 34-phenylacetophenone

[0019] Add palladium acetate (0.0025 mmol), imidazolium salt A (0.01 mmol), 4-bromoacetophenone (0.5 mmol), phenylboronic acid (0.75 mmol), triethylamine (1.0 mmol) and water (1 mL) to the circle in sequence In a bottom flask, the reaction was stirred at 100°C for 5 minutes. After the reaction was completed, 10 mL of saturated brine was added to quench the reaction, the reaction mixture was extracted with 10 mL of ethyl acetate for 3 times, the organic phase was combined and concentrated to obtain a crude product, and the target product was obtained by column chromatography (eluent was petroleum ether). product structure through 1 H NMR and mass spectral identification. The separation yield reached 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com