Inert gas system for floating type oil storage-and-discharge device

An inert gas and floating technology, applied in the field of inert gas system, can solve the problem of limited effect of flue gas volume, and achieve the effect of reducing diesel consumption and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

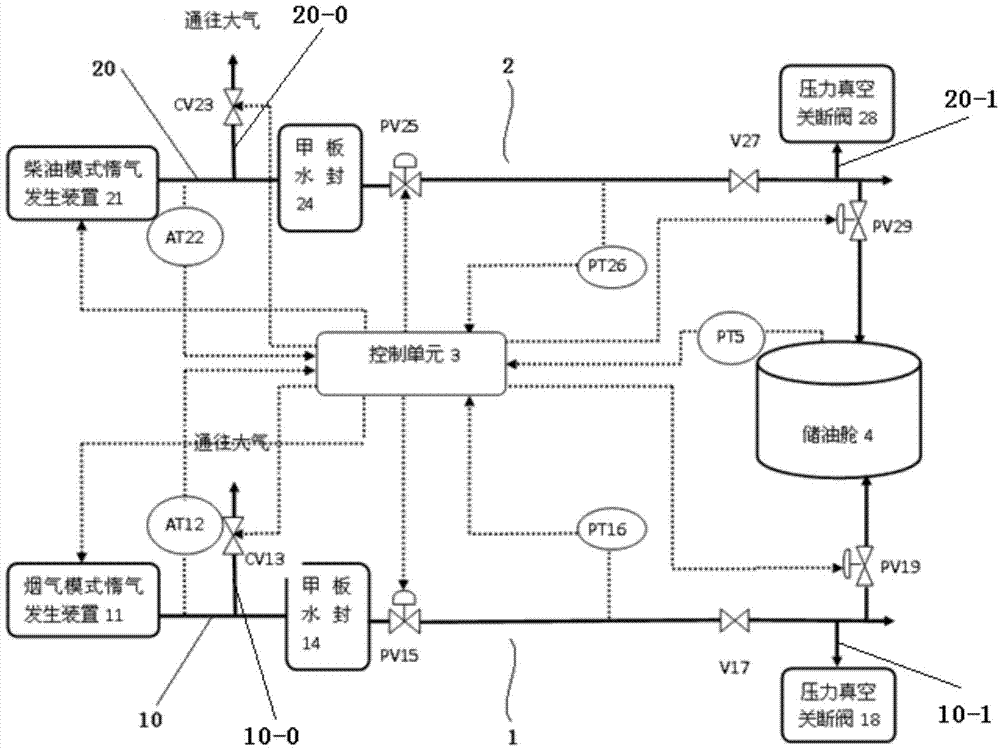

[0013] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the present invention can deliver inert gas to multiple oil storage tanks simultaneously, and now only the inert gas delivery to one oil storage tank will be described in detail.

[0014] like figure 1 As shown, the present invention includes a flue gas mode inert gas unit 1 , a diesel mode inert gas unit 2 , a control unit 3 , an oil storage tank 4 and an oil tank pressure transmitter (PT) 5 . Among them, the smoke mode inert gas unit 1 and the diesel mode inert gas unit 2 are independently connected to the oil storage tank 4, and the inert gas pressure signal in the oil storage tank 4 is detected by the oil tank pressure transmitter 5 and transmitted to the control unit 3 , the control unit 3 adjusts the pressure of the oil storage tank 4 according to the inert gas pressure signal.

[0015] The flue gas mode inert gas unit 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com