A processing equipment, process and application of shaped straw powder

A processing equipment and technology for straw powder, applied in the field of processing equipment for forming straw powder, can solve problems such as difficulty in straw transportation and storage, energy waste, air pollution, etc., and achieve the effects of saving primary energy coal, reducing costs, and improving bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In the present invention, the preparation process of shaped straw and the shaped straw powder preparation process may not be in the same area, but may be separated by several kilometers, or they may be in the same area. The shaped straw storage can be set in the area where the shaped straw is prepared, or in the area where the shaped straw powder is prepared, or can be set in both areas, or neither can be set.

[0041] Various machines involved in the processing equipment of the present invention can adopt the prior art, and other powder metering and conveying equipment are equally applicable to the present invention. In the present invention, the connection between the formed straw powder burner and the decomposition furnace is not limited to one.

[0042] The process principle of the processing technology of the molded straw powder of the present invention is: when the straw is compressed and molded, due to the temperature above 70°C, the structure of the straw change...

Embodiment 1

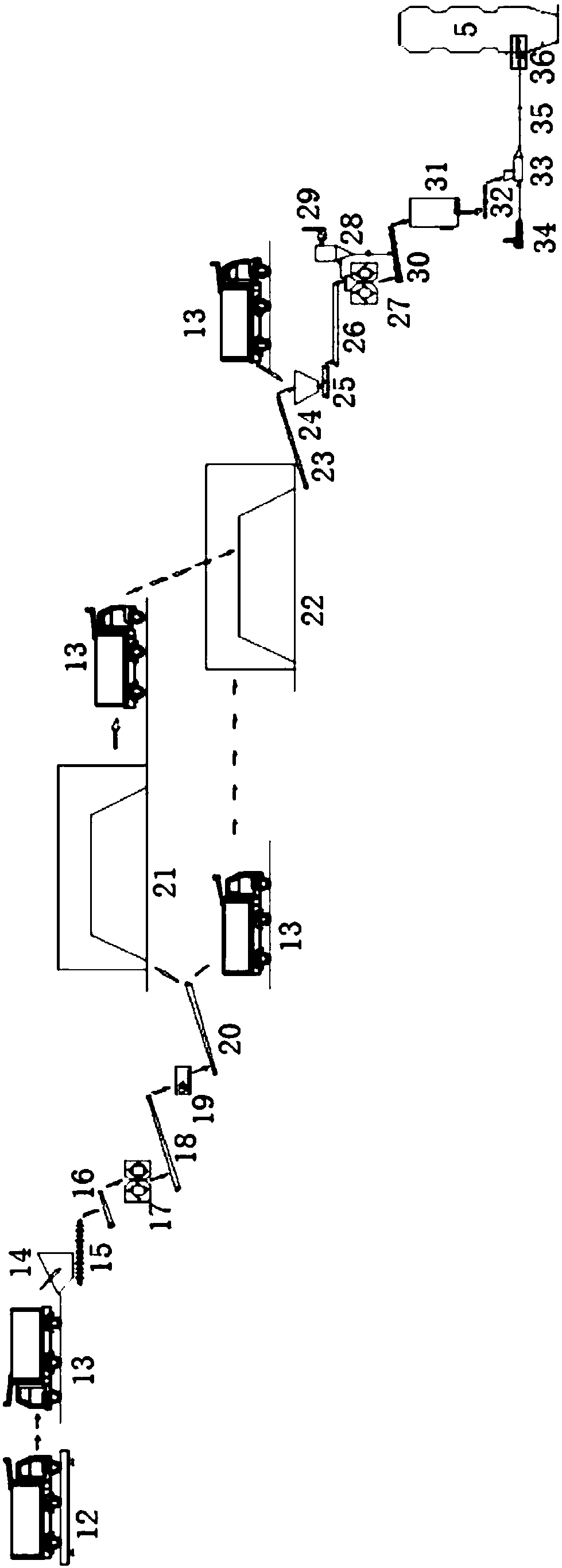

[0045] The processing equipment for forming straw powder in this embodiment includes a straw measuring ground balance 12, a straw collecting hopper 14, a straw feeder 15, a first belt conveyor 16, a straw crusher 17, a second belt conveyor 18, and a straw forming machine. 19. The third belt conveyor 20, the formed straw unloading pit 24, the quantitative feeder 25, the fifth belt conveyor 26, the formed straw pulverizer 27, the bag dust collector 28, the exhaust fan 29, the formed straw powder screw conveyor 30 and forming straw powder storage bin 31; above-mentioned straw metering ground balance 12, straw collecting hopper 14, straw feeder 15, first belt conveyor 16, straw crusher 17, second belt conveyor 18, straw molding machine 19 and the third belt conveyor 20 are connected in turn according to the process conditions, and the materials in the third belt conveyor 20 are directly poured into the first forming straw storage warehouse 21 or transported to the second forming st...

Embodiment 2

[0051]The connection relation of the processing equipment of the molding straw powder of this embodiment and the step of process are the same as that of Embodiment 1, the difference is that the first molding straw storage house 21 is not set for the straw of this embodiment, and the molding straw is directly delivered by the transportation means (truck 13) Enter the second molding straw storage warehouse 22 or molding straw unloading pit 24. This embodiment is applicable to the situation that the molded straw storage can be arranged on the site of the cement factory.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com